Disassembling and assembling equipment for waste desktop computer case

A technology for desktop computers and assembly equipment, which is applied to workbenches, hand-held appliances, and electronic waste recycling, etc. It can solve the problem of low disassembly efficiency, install all parts on one side of the chassis partition, and possibly install the hardware on the chassis partition Both sides of the machine, hardware waste, etc., to achieve the effect of improving disassembly efficiency and improving disassembly and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described below in conjunction with drawings and embodiments.

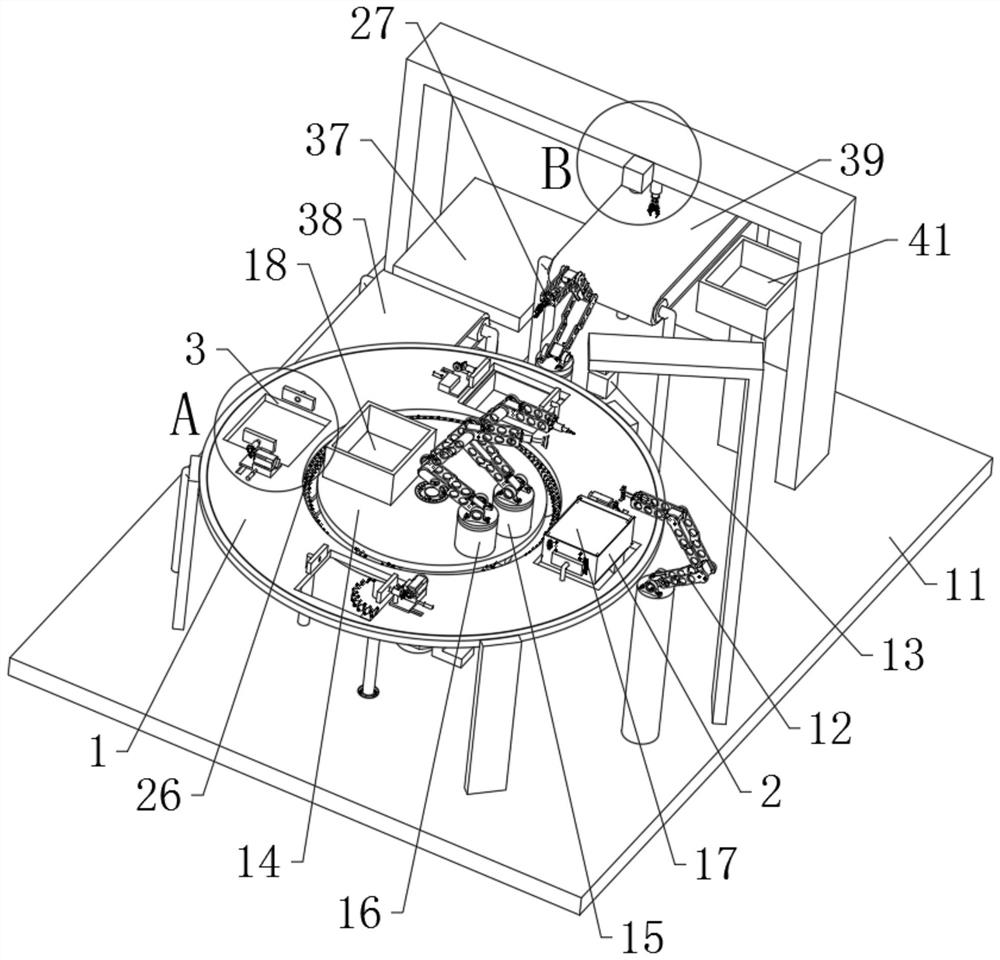

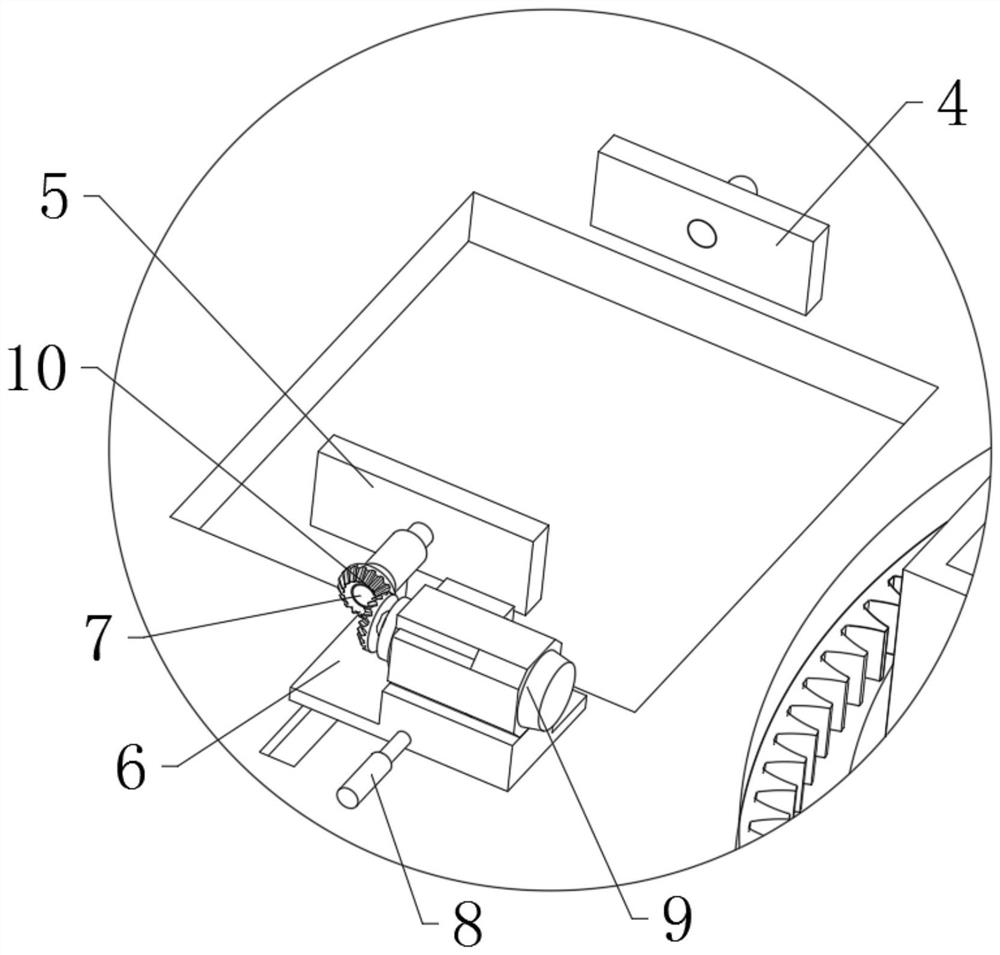

[0040] like Figure 1 to Figure 7 As shown, a disassembly and assembly equipment for waste desktop computer cases includes a rotating ring 1 that can rotate on its own, and a number of flipping and clamping units are arranged in a circular array around the rotating axis of the rotating ring 1, and the flipping and clamping units The units can hold the waste case 2 and drive the waste case 2 to turn and flip;

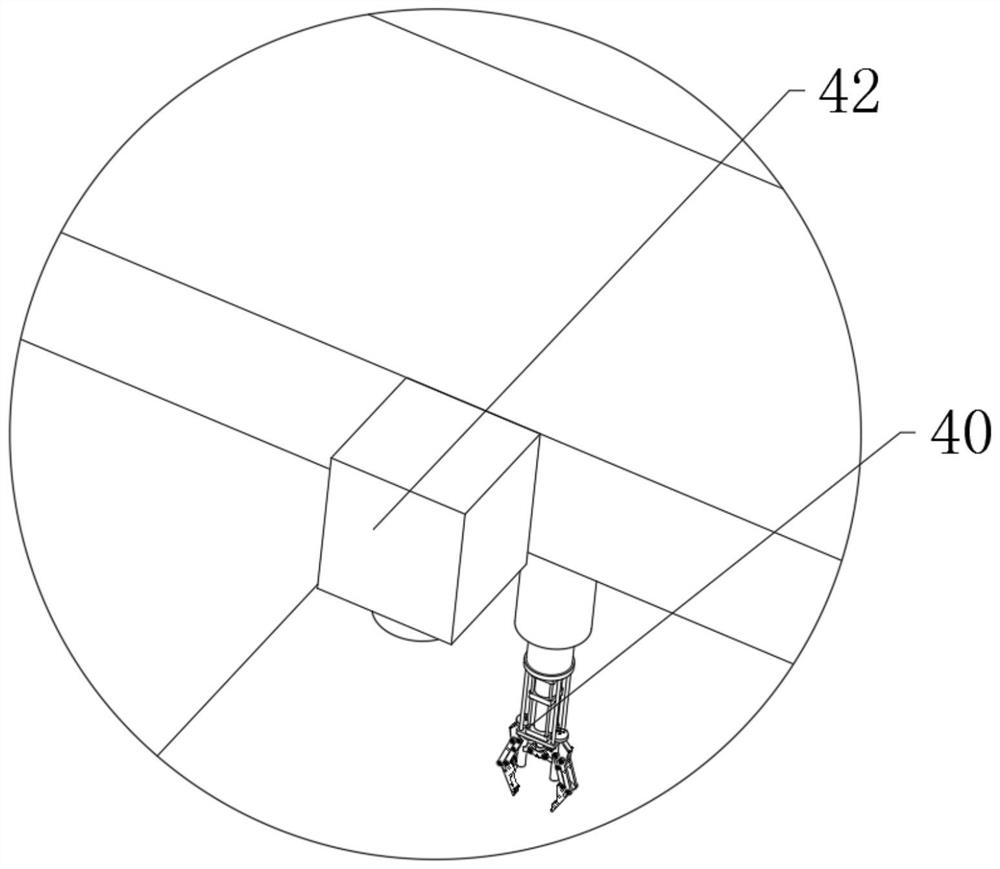

[0041] The moving path of the waste cabinet 2 is sequentially provided with a dismantling and picking unit, a hardware taking unit and a shell lowering unit corresponding to the waste chassis 2, and the disassembling and picking unit, the hardware taking unit and the shell lowering unit are arranged around The rotation axis of the rotating ring 1 is arranged in a circular array and the array angle is equal to the array angle of the flip clamping unit;

[0042] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com