Maintenance device for concrete precast slab production

A prefabricated slab and concrete technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low work efficiency, easy water splashing, and unfavorable cleanliness of the interior of the workshop, and achieves the effect of strong practicability and improved maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

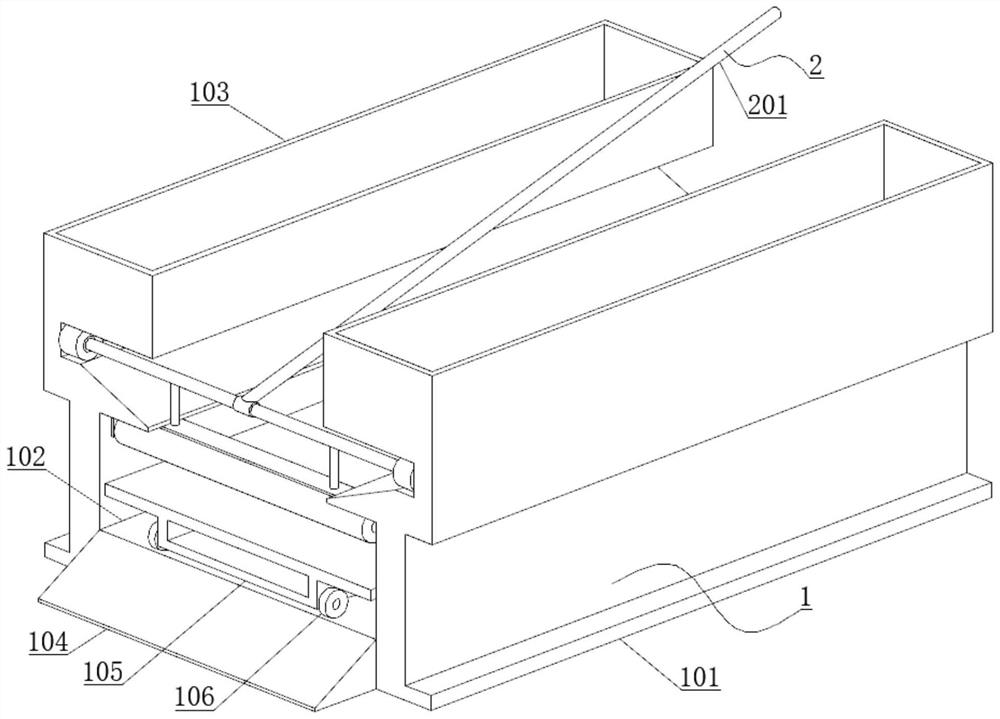

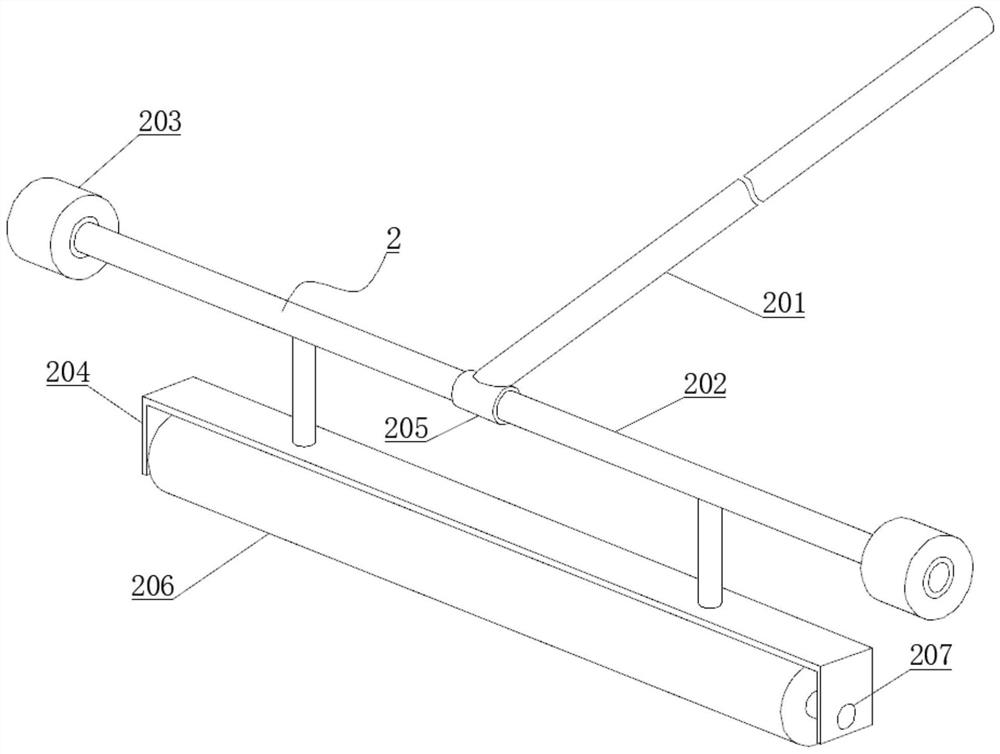

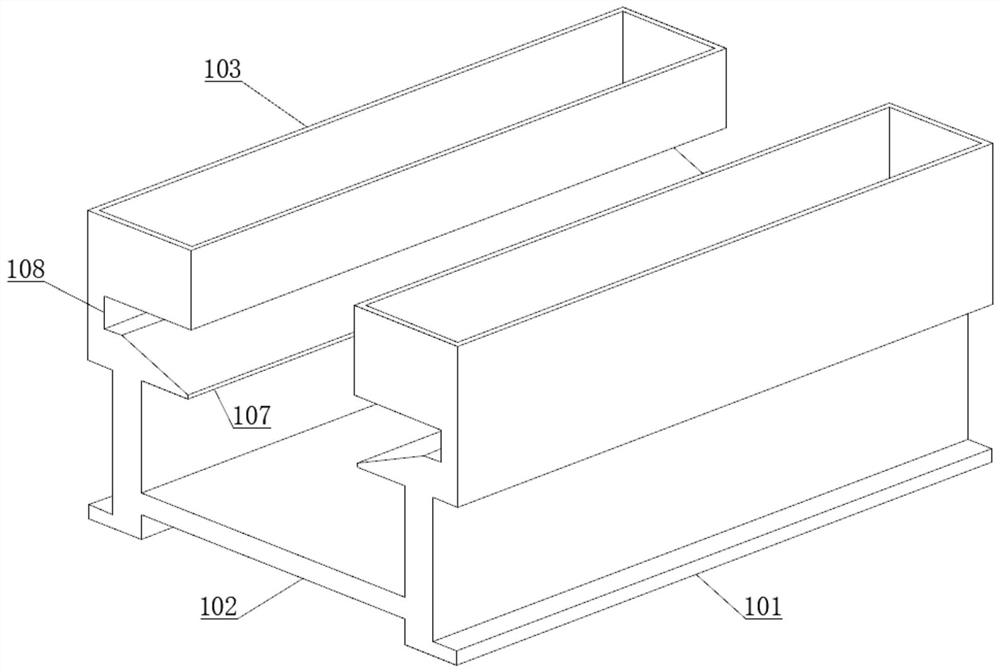

[0022] see Figure 1-Figure 8 , the present invention provides the following technical solutions: a curing device for the production of concrete prefabricated slabs, including a prefabricated slab curing platform 1, the prefabricated slab curing platform 1 includes a curing platform side frame 101, and the curing platform side frame 101 is provided with two, and two The side frames 101 of the curing table are arranged parallel to the mirror image, a trolley placement seat 102 is arranged between the two side frames 101 of the curing table, and a maintenance water storage tank 103 is arranged on the top of the side frames 101 of the curing table, and a bottom end of the side frame 101 of the curing table The side is provided with the slope plate 104 of the maintenance platform,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap