Roundness detection device

A detection device and roundness technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as single detection form, difficulty in detecting roundness, errors, etc., and achieve the effect of simple structure of parts, high level of automation, and great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

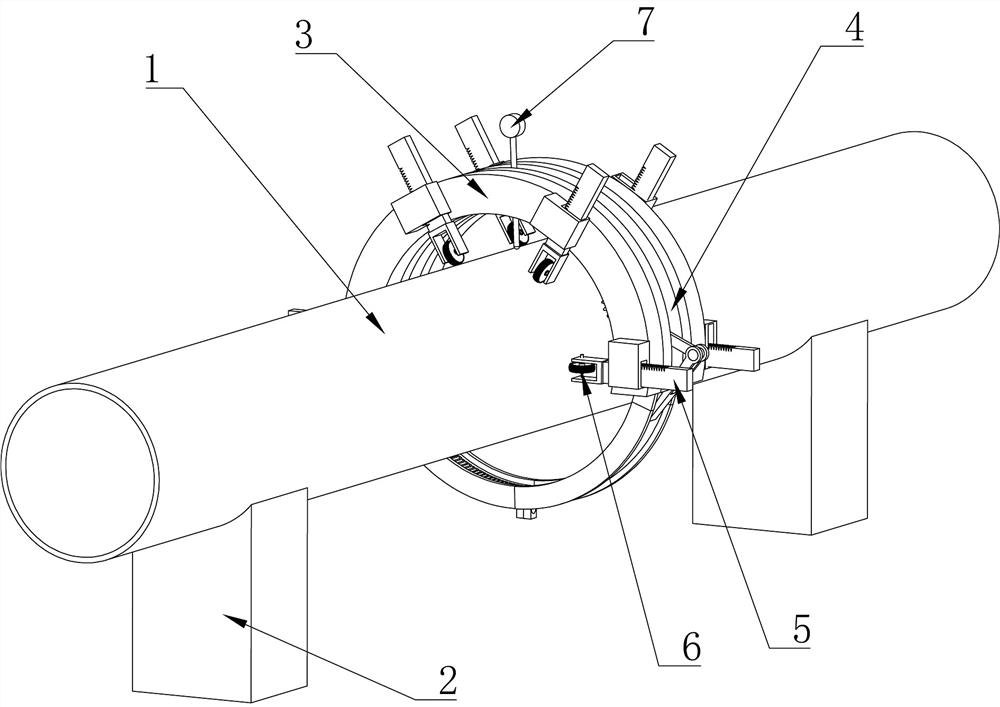

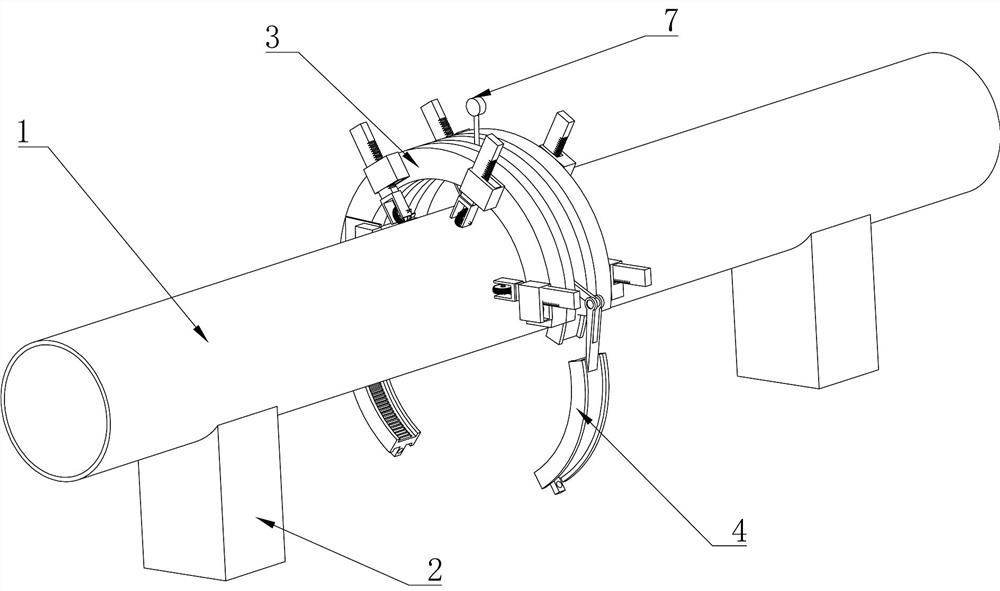

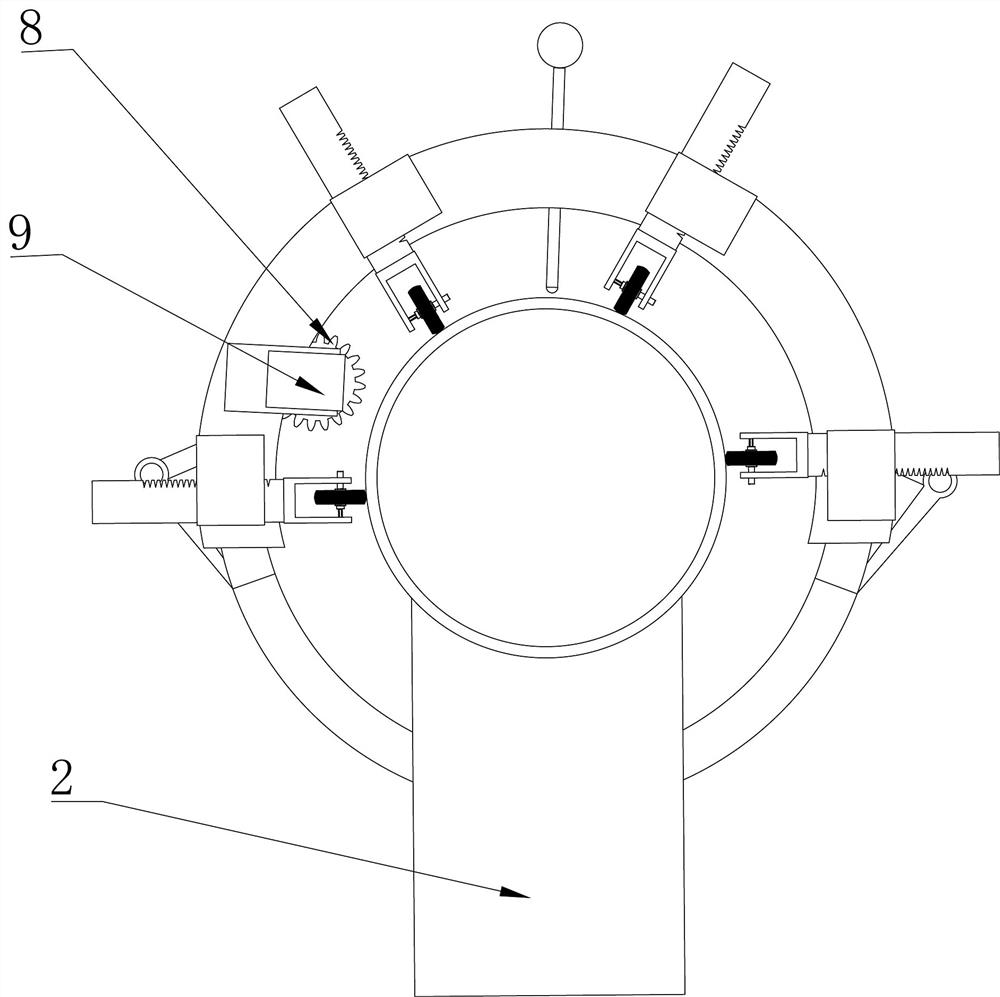

[0031] Such as Figure 1-7 Among them, a roundness detection device, a steel pipe 1 is supported on a bracket 2, which is characterized in that it includes two fan-shaped clamping devices 3 installed on the steel pipe 1, and multiple pointing clamping devices 3 are arranged on the clamping device 3 The telescopic rod 5 in the center of the circle is provided with a rotating device 4 that can be opened and closed between the two clamping devices 3. The rotating device 4 is slidably connected with the two clamping devices 3. Roundness table 7 for up and down adjustment;

[0032] Simultaneously drive a plurality of telescopic rods 5 to expand and contract, so that the center of the clamping device 3 coincides with the center of the steel pipe 1, adjust the roundness gauge 7, make the roundness gauge 7 lean against the steel pipe 1, and drive the rotating device 4 relative to the clamping device 3 Rotate so that the roundness meter 7 measures the roundness of the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com