Train collision test waveform simulation system

A crash test and simulation system technology, applied in the field of train crash test waveform simulation system, can solve problems such as difficult implementation and complex structure, and achieve the effects of improving reliability, reducing implementation difficulty, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

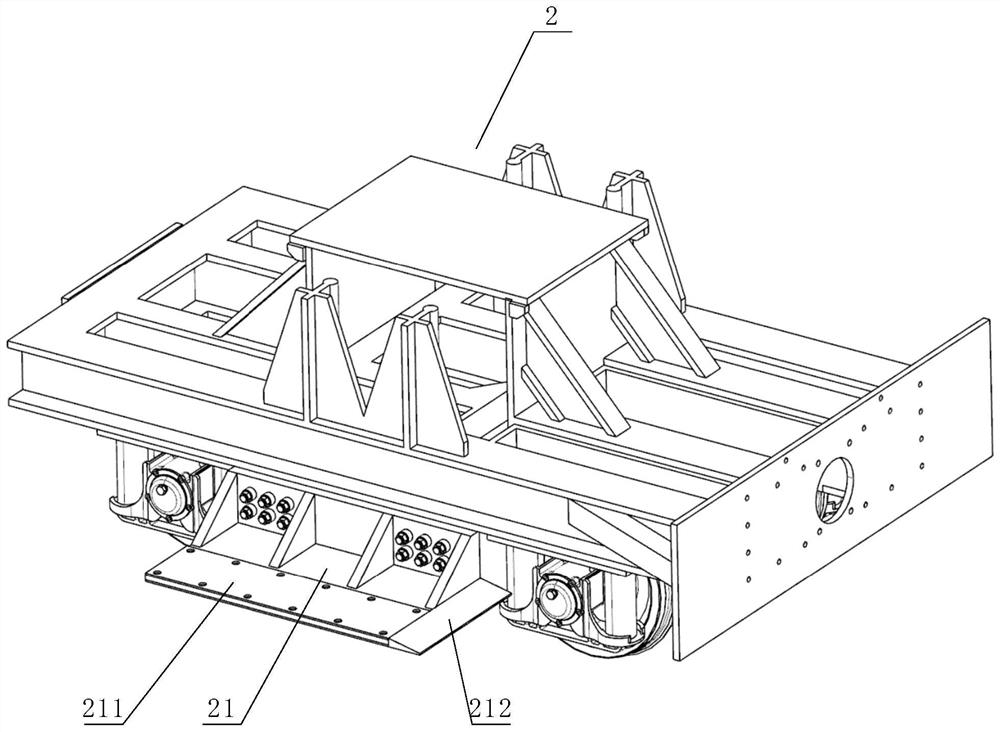

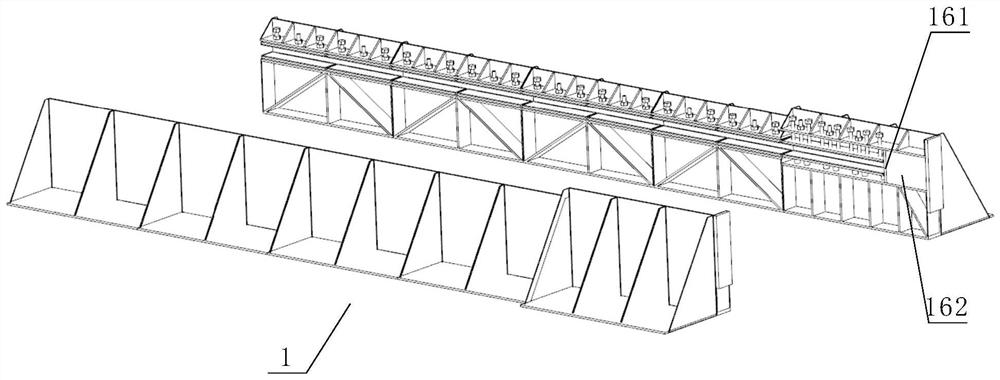

[0032] Such as Figure 1 to Figure 3 As shown, in the first embodiment of the train crash test waveform simulation system of the present invention, it includes: a waveform controller 1 and a trolley 2;

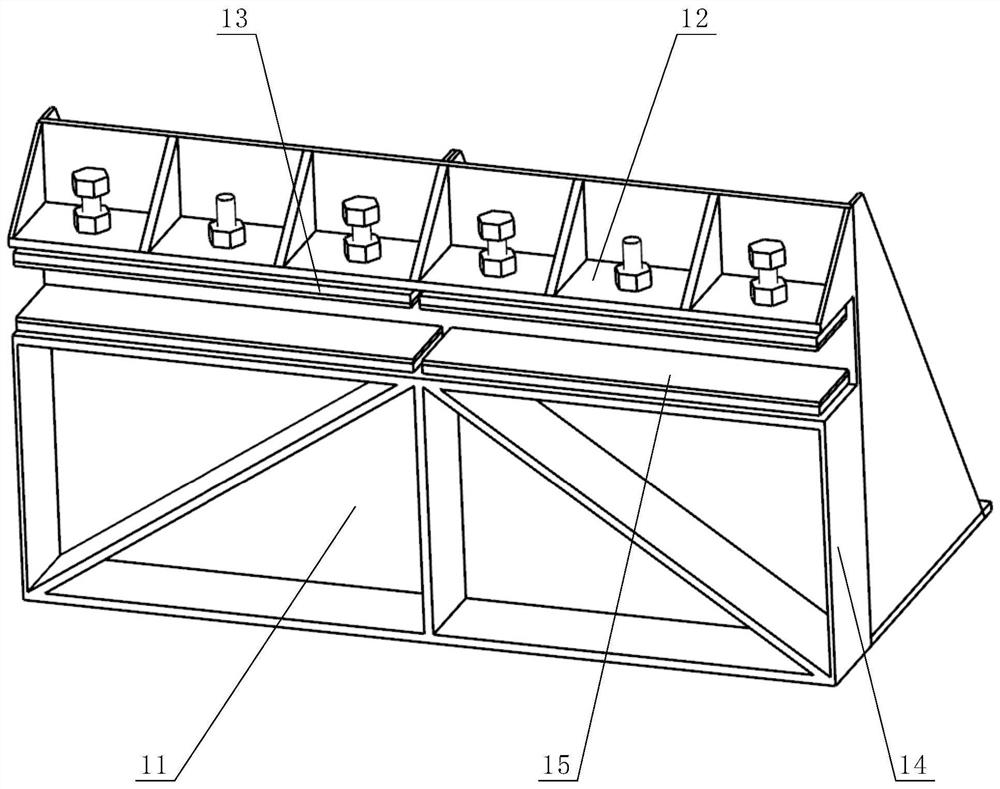

[0033] The waveform controller 1 includes a pair of pedestals 11 mirrored on both sides of the traveling direction of the trolley 2, and the pedestals 11 are fixedly connected to the foundation; the side of the pedestal 11 facing the trolley 2 is provided with an upper support seat 12 extending along the traveling direction , and an upper friction plate 13 is installed under the upper support seat 12;

[0034] The trolley 2 is provided with side wings 21 on both sides along the traveling direction; the upper surface of the side wings 21 can rub against the lower surface of the upper friction plate 13 to reduce the speed of the vehicle to simulate a collision waveform.

[0035] By setting the upper support seat 12 and the upper friction plate 13 on the waveform controller 1 ar...

Embodiment 2

[0037] Such as Figure 4 As shown, the second embodiment of the train crash test waveform simulation system of the present invention, the waveform simulation system is basically the same as Embodiment 1, the difference is:

[0038] In this embodiment, the upper support seat 12 and the upper friction plate 13 are connected by lower jacking bolts 31 and lifting bolts 32 alternately distributed along the traveling direction;

[0039] The tail of the lower jack bolt 31 passes through the upper support seat 12 and abuts against the upper friction plate 13, and the lower jack bolt 31 can push the upper friction plate 13 away from the upper support seat 12;

[0040] A countersunk groove is formed on the lower surface of the upper friction plate 13, the head of the lifting bolt 32 is embedded in the countersink groove, and the tail part passes through the upper support seat 12, and the upper friction plate 13 can be pulled closer to the upper support seat 12 by the lifting bolt 32;

...

Embodiment 3

[0044] The third embodiment of the train crash test waveform simulation system of the present invention, the waveform simulation system is basically the same as Embodiment 2, the difference is that:

[0045] In this embodiment, the side of the pedestal 11 facing the trolley 2 is provided with a lower support seat 14 extending along the direction of travel, and a lower friction plate 15 is installed above the lower support seat 14; 15 friction occurs on the upper surface to reduce the speed of the vehicle to simulate the collision waveform.

[0046] Similar to the function of the upper friction plate 13, in order to increase the friction force, a lower support seat 14 is provided on the side of the pedestal 11 facing the trolley 2, and a lower friction plate 15 is installed above the lower support seat 14, when the trolley 2 slides When reaching the area clamped by the waveform controller 1, the side wings 21 slide into the upper side of the lower friction plate 15. At this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com