Safety production risk detection and inspection personnel distribution method based on artificial intelligence

A technology of safe production and artificial intelligence, applied in the direction of neural learning methods, image analysis, biological neural network models, etc., can solve problems such as unreasonable dispatch or allocation of personnel, unfavorable equipment risk investigation, failure to consider the cooperative relationship of faulty equipment, etc., to achieve Reduce risks, avoid blind allocation, and increase safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

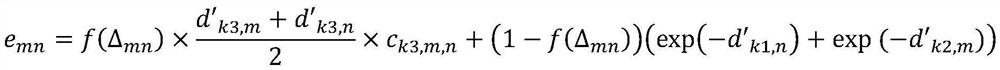

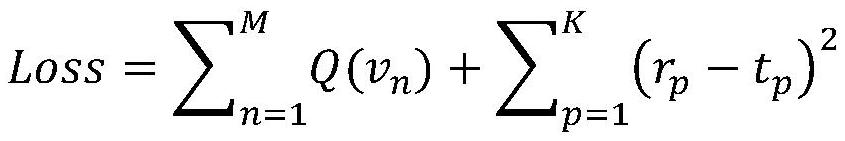

[0023] This embodiment provides an artificial intelligence-based safety production risk detection and inspection personnel assignment method, specifically, the method includes:

[0024] 1) Obtain the first collaborative correlation degree set of each device, the first collaborative correlation degree set includes the first collaborative correlation degree between any two personnel, the first collaborative correlation degree reflects the The degree of need for any two persons.

[0025] Due to differences in the technical ability, job responsibilities, and safety awareness of different personnel, and considering that some equipment requires mutual assistance from multiple personnel to complete the inspection and maintenance of the equipment, the core purpose of the present invention is mainly to allocate personnel reasonably. In groups, people in the same group assist each other to reduce or suppress the probability of specific equipment risks. Therefore, it is first necessary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com