Automatic ultrasonic cleaning device for semiconductor chemical mechanical grinding precision part

An ultrasonic cleaning and chemical-mechanical technology, applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as difficulty in placing parts and poor cleaning effect, achieve quality control and improve work. Efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

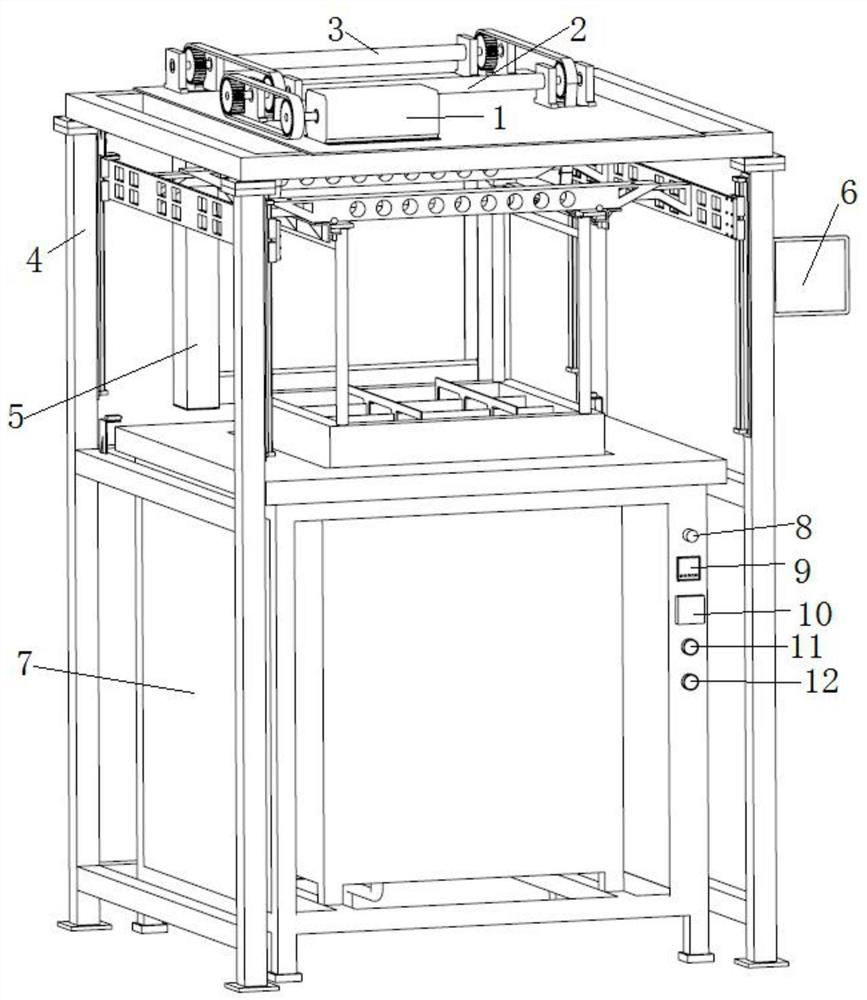

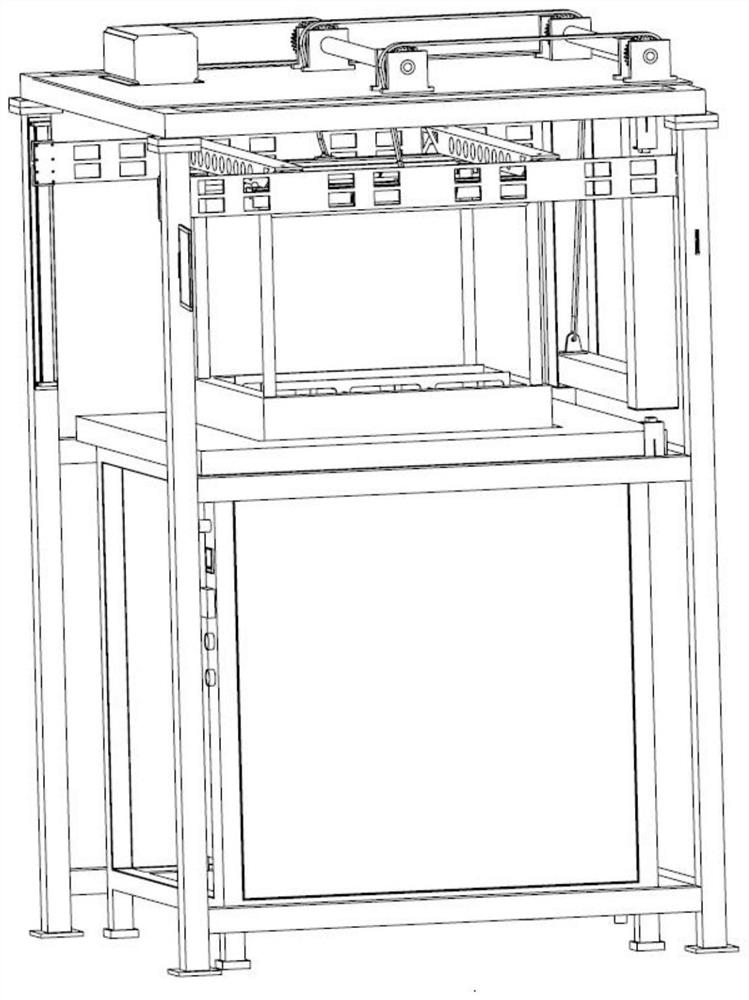

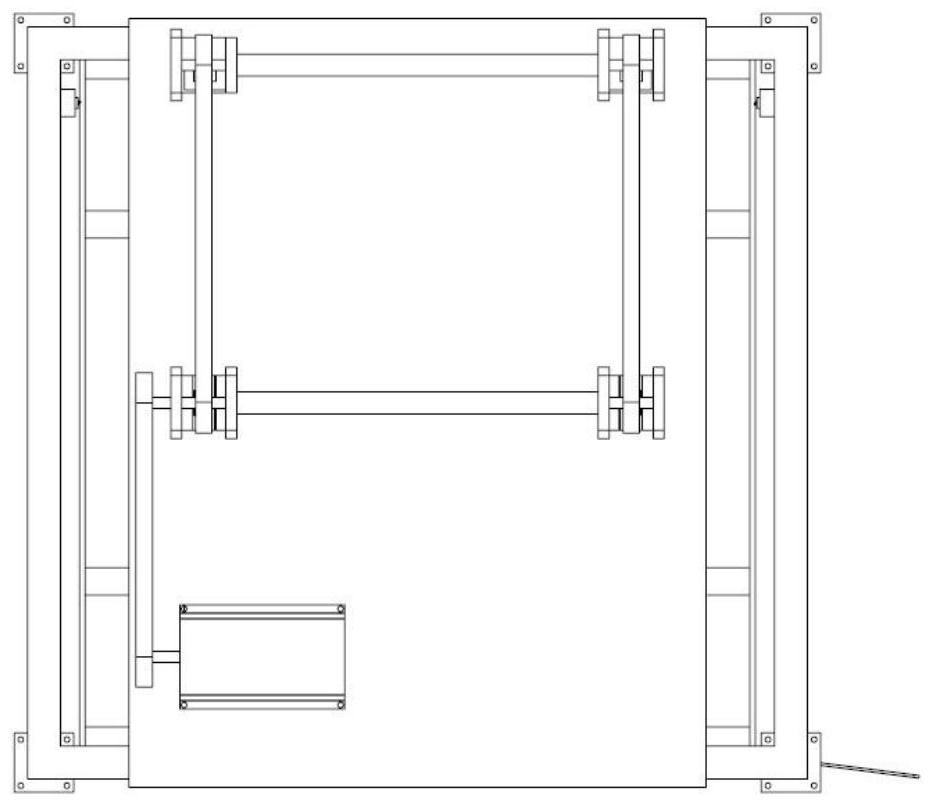

[0025] This embodiment provides an automatic ultrasonic cleaning device for semi-conductor chemical mechanical grinding precision parts, including a support frame, the top of the support frame is provided with a motor transmission device, the motor transmission includes a motor and two transmission shafts, the motor can realize forward rotation and Reverse function; there are three gears on the transmission shaft a, and two gears on the transmission shaft b, such as figure 1 As shown, the driving gear on the motor is connected to the driven gear of transmission shaft a through a chain, and the other two gears of transmission shaft a and the two gears of transmission shaft b are also connected through two chains, one end of the two chains is connected to The lifting beam of the lifting device is connected, and the other ends of the two chains are connected with the gravity block. When the motor performs forward rotation and reverse rotation, the parts carrying device will be dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com