A portable generator set based on draw rod architecture

A generator set and pull rod technology, which is applied in the directions of engine components, machines/engines, mechanical equipment, etc., can solve the problems of laborious handling of generator sets, poor adaptability to road conditions, and easy collision with operators, and achieves portability and operation. The convenience is improved, the volume of the whole machine is reduced, and the effect of the operation interface is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

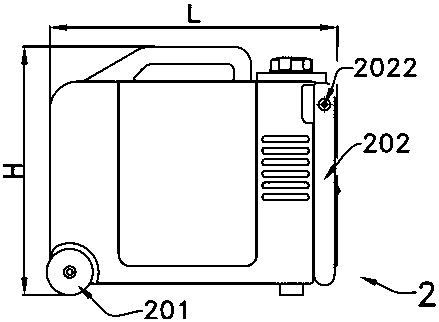

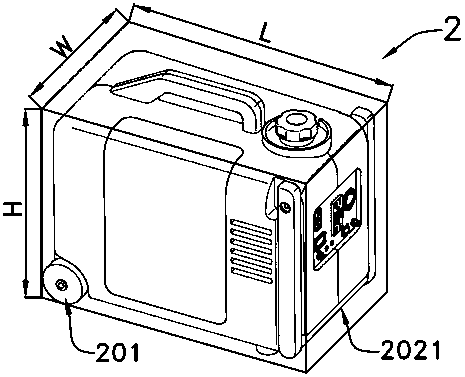

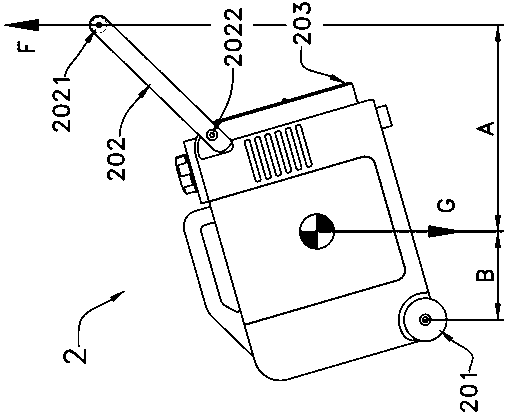

[0055] Such as Figure 3a to Figure 19 As shown, the portable generator set 1 of the present invention is mainly composed of a motor 6, a generator 7, an inverter 11, a roller device 3, a pull rod device 4, a casing 5, and an electrical panel 10.

[0056] Such as Figure 12 and Figure 14 As shown, the engine 6 of the present embodiment is an inclined cylinder engine, and the multistage permanent magnet generator 7 is arranged at the rear of the engine and is connected with the output end of the rear of the crankshaft of the engine, belonging to a post-mounted generator. Of course, the vertical cylinder engine can also be selected as required, and the front generator can be used to reduce the width W of the generator set. An inverter 11 is arranged at the front of the engine, and the inverter 11 is used to convert the intermediate frequency alternating current output by the multistage permanent magnet generator 7 into a power frequency alternating current with stable voltage...

Embodiment 2

[0086] Compared with the first embodiment, the main difference of the second embodiment is that the electrical panel 10 and the electrical box 506 are arranged on the right side 104 of the generator set.

[0087] Such as Figure 20 and Figure 21 As shown, the electrical panel 10 and the electrical box 506 of this embodiment are arranged on the right casing 502 between the two rod barrels 402 of the pull rod device 4 , and the electrical box 506 is connected to the right casing 502 . In this embodiment, the electrical panel 10, the starter handle 609, and the choke handle 611 are concentrated on the same side of the casing 5, which is beneficial to improve the operation convenience of the generator set.

Embodiment 3

[0089] Compared with embodiment one, the main difference of embodiment three is:

[0090] The casing 5 has different structures, such as Figure 22 to Figure 26 As shown, the casing 5 in this embodiment is composed of a left casing 501 and a right casing 502, without a separate lower casing, a maintenance cover 504 is arranged on the right casing 502, and the air inlet 505 of the generator set 1 It is also arranged on the right casing 502. Two damping feet 509 are arranged on the bottom of the left casing 501 and the right casing 502 respectively, and four foot pads 510 are arranged on the side of the left casing 501 .

[0091] The connection mode of engine 6 and casing 5 is different, as Figure 22 and Figure 26 As shown, the bottom of the engine 6 in this embodiment is provided with two connection holes in parallel, and a sleeve is arranged in the connection hole, and the sleeve and the connection hole are connected by a rubber sleeve for shock absorption, and one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com