Pipe penetrating device and method for large-diameter pipeline

A pipe-piercing device and large-diameter technology, which is applied in the direction of pipeline protection, pipe/pipe joint/fitting, pipeline damage/wear prevention, etc. It can solve the problems of pipeline use and anti-corrosion ability, anti-corrosion layer damage, etc., to achieve light weight, No jamming, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

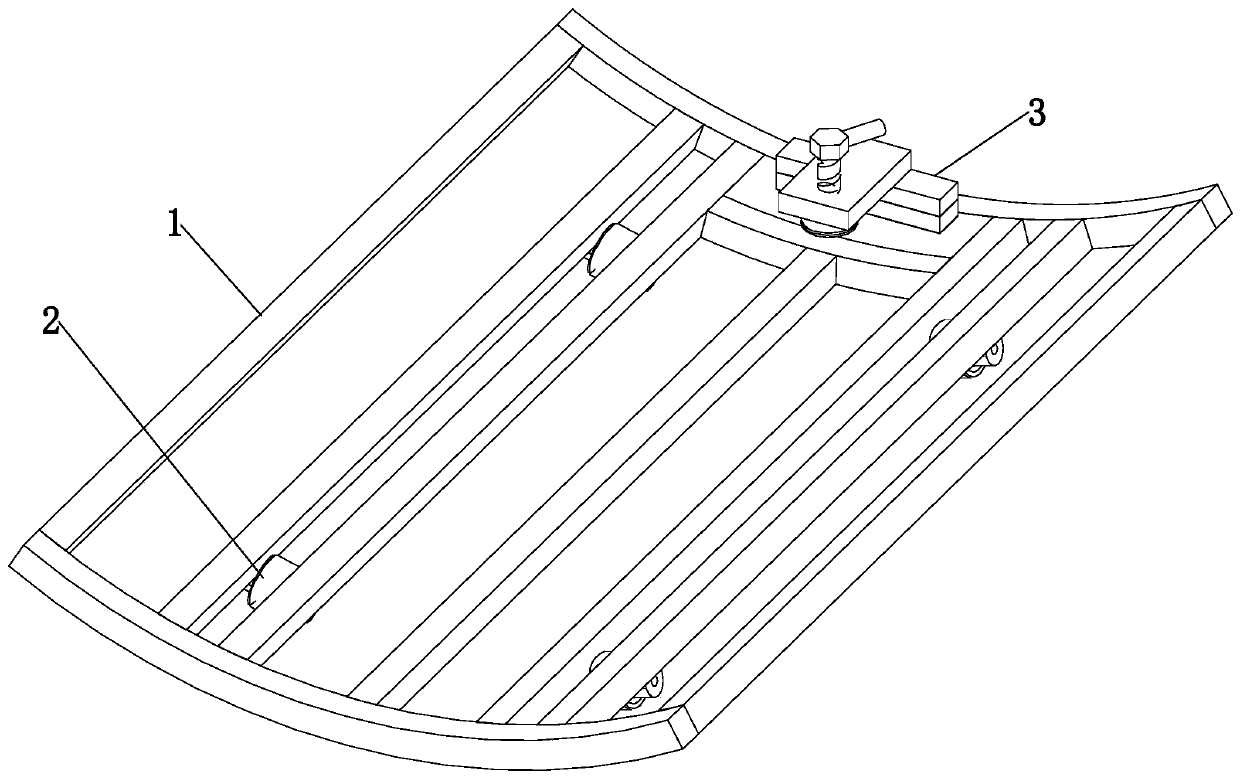

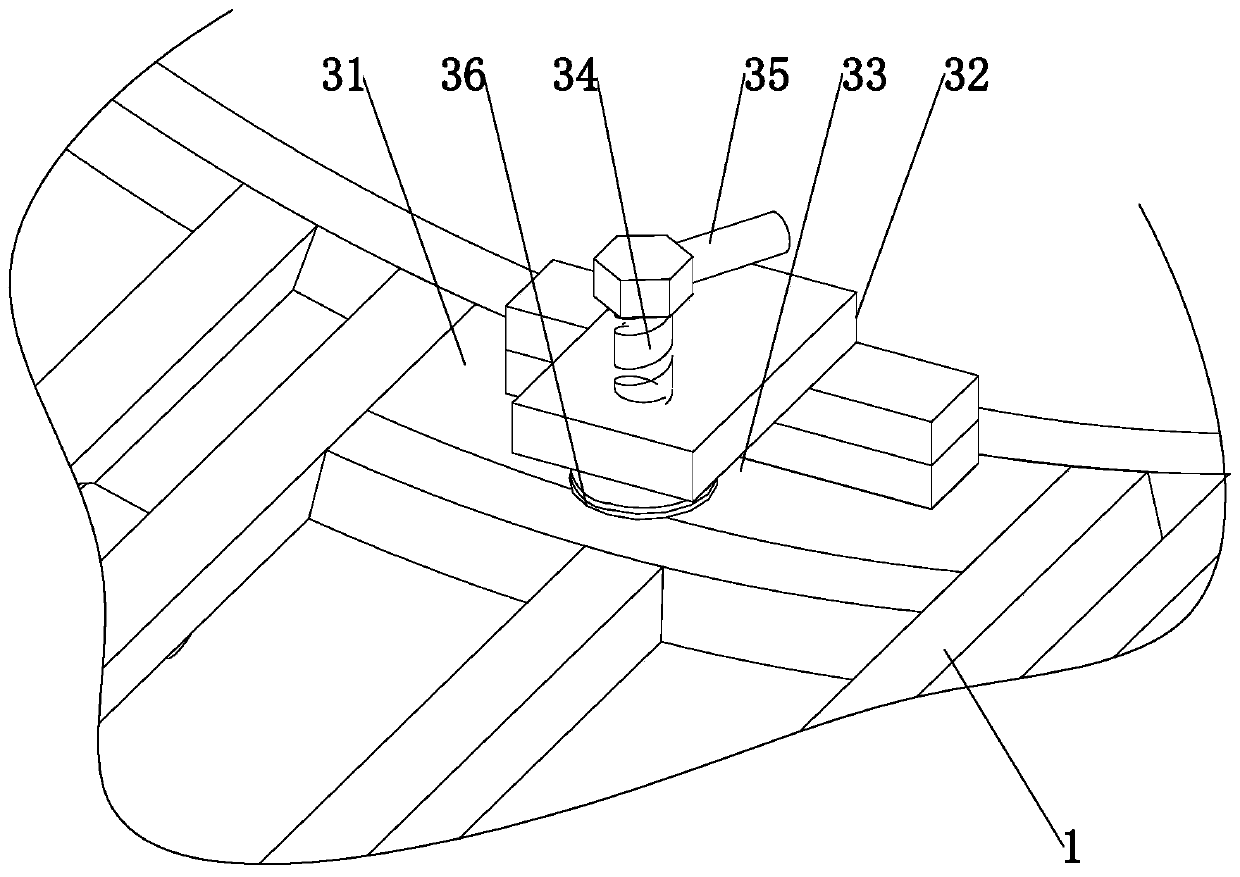

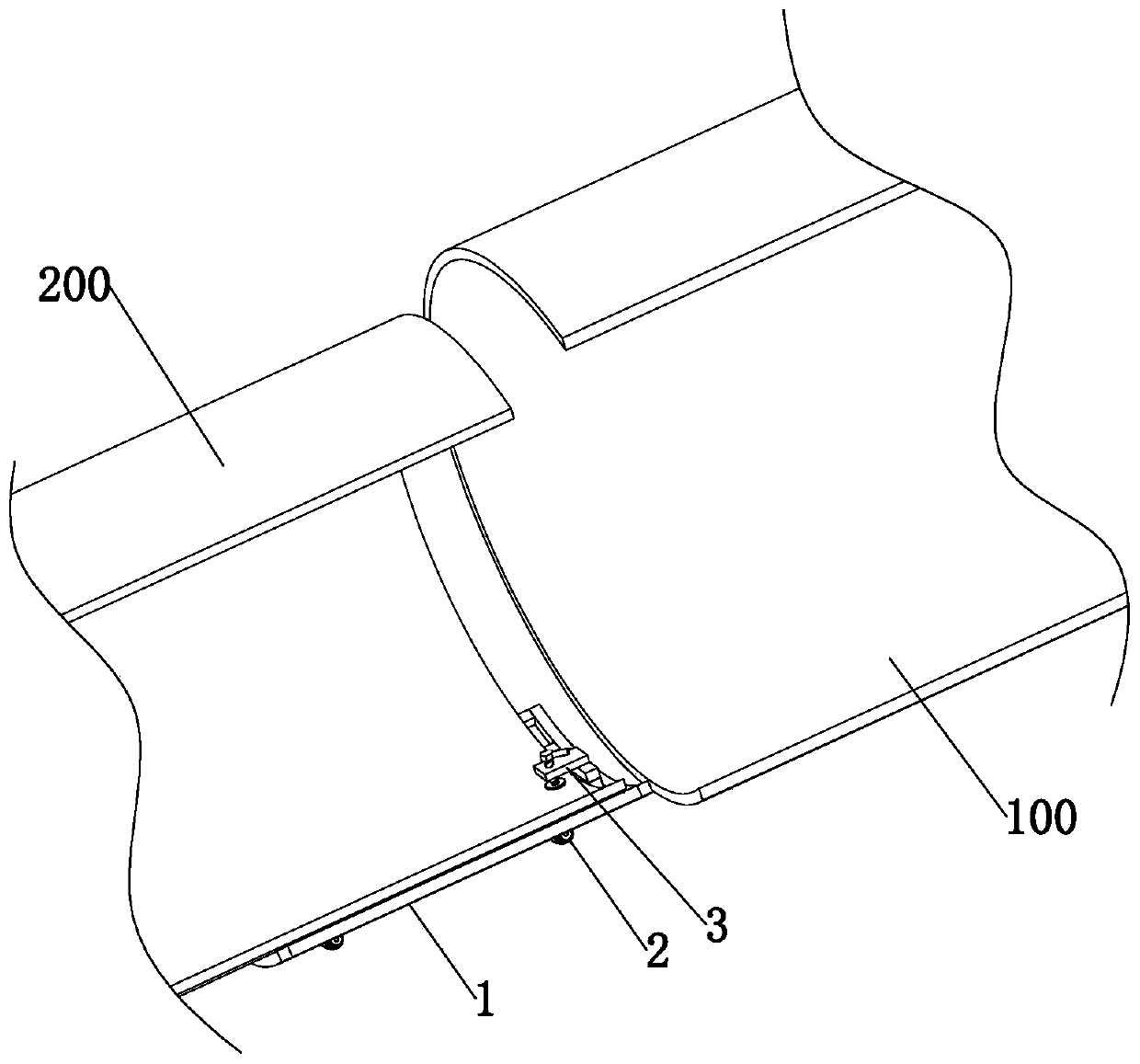

[0039] refer to figure 1 , is a large-diameter pipe threading device disclosed in the present invention, which includes a three-part structure of a car body 1, a traveling wheel 2 and a pipe gripper 3. Among them, the car body 1 is used as a load-bearing and supporting structure, bearing the weight of the front end of the pipe body, and lifting the pipe body; the traveling wheel is used as a walking fulcrum, driving the car body to move forward; Clamp and fix so that the car body can walk with the pipeline.

[0040] The car body 1 has an arc-shaped structure, and can be an arc-shaped frame body formed by connecting metal rods or an arc-shaped plate body formed by bending a metal plate. In this embodiment, the car body 1 is welded by metal pipes, and the metal pipes are made of A 20mm×3.14mm square tube, including two curved tubes bent into an arc, and multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com