Long U-shaped metal plate bending equipment

A metal plate and U-shaped technology, which is applied in the field of long U-shaped metal plate bending equipment, can solve the problems of limited bending range, low processing efficiency, and low quality, and achieve good bending effect, convenient operation, and low processing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

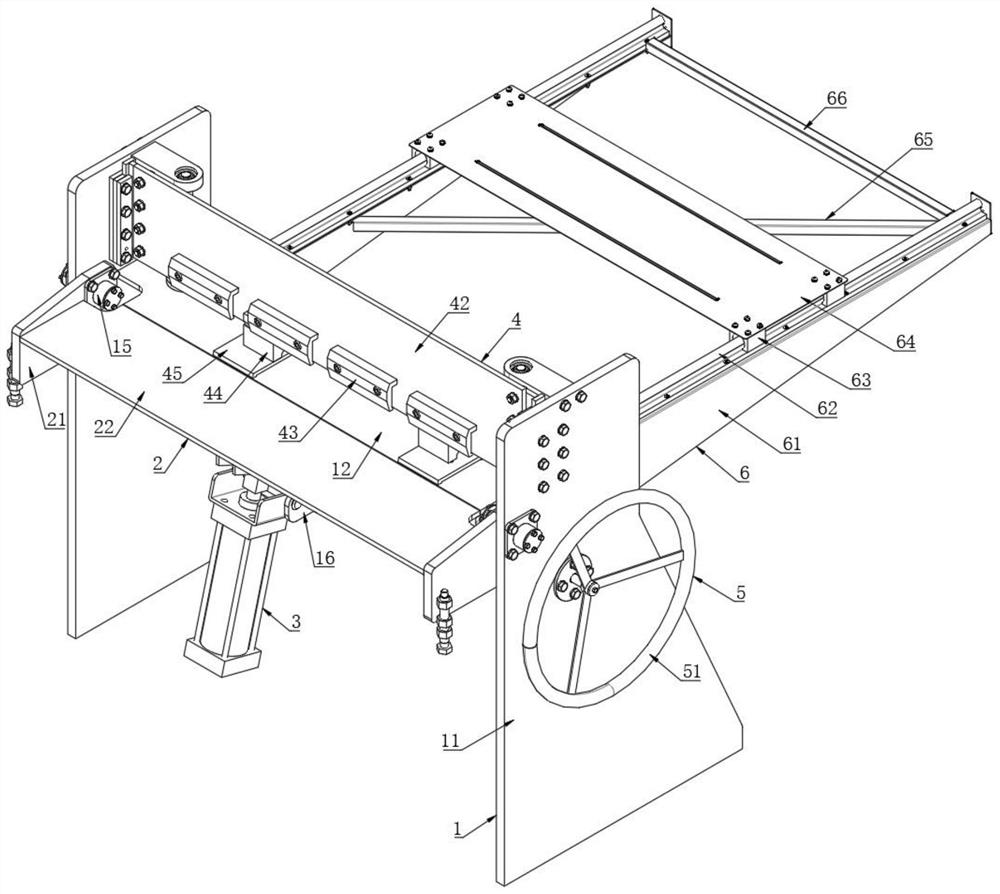

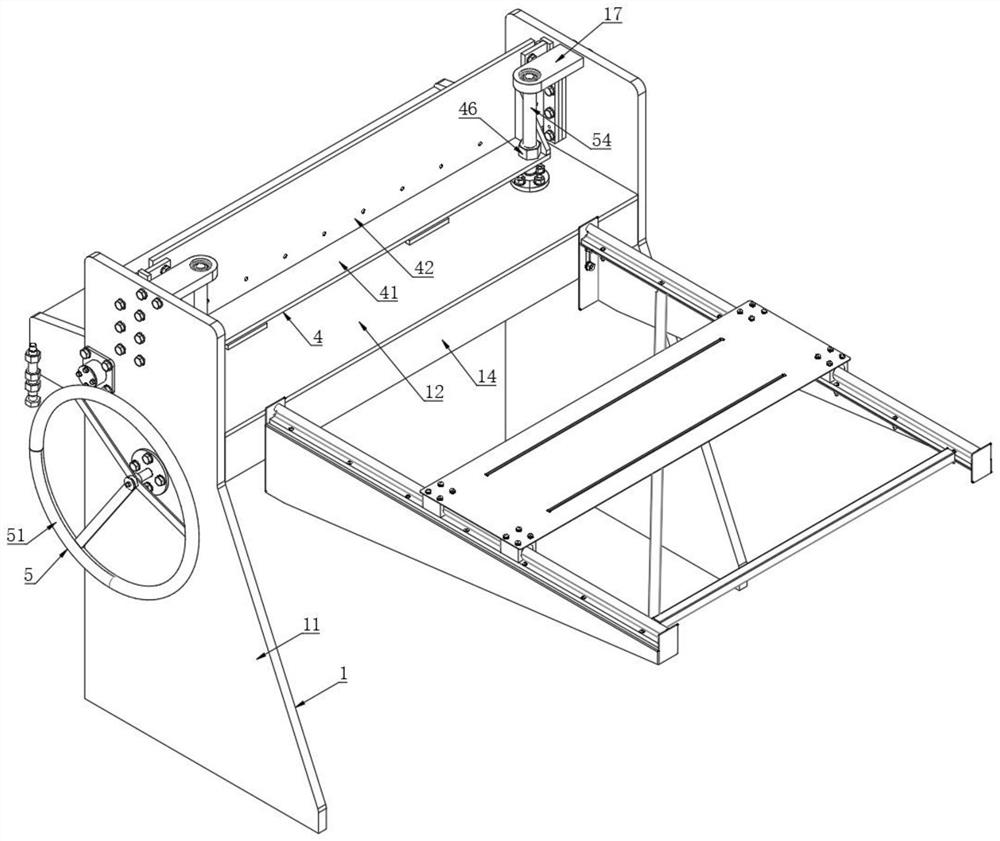

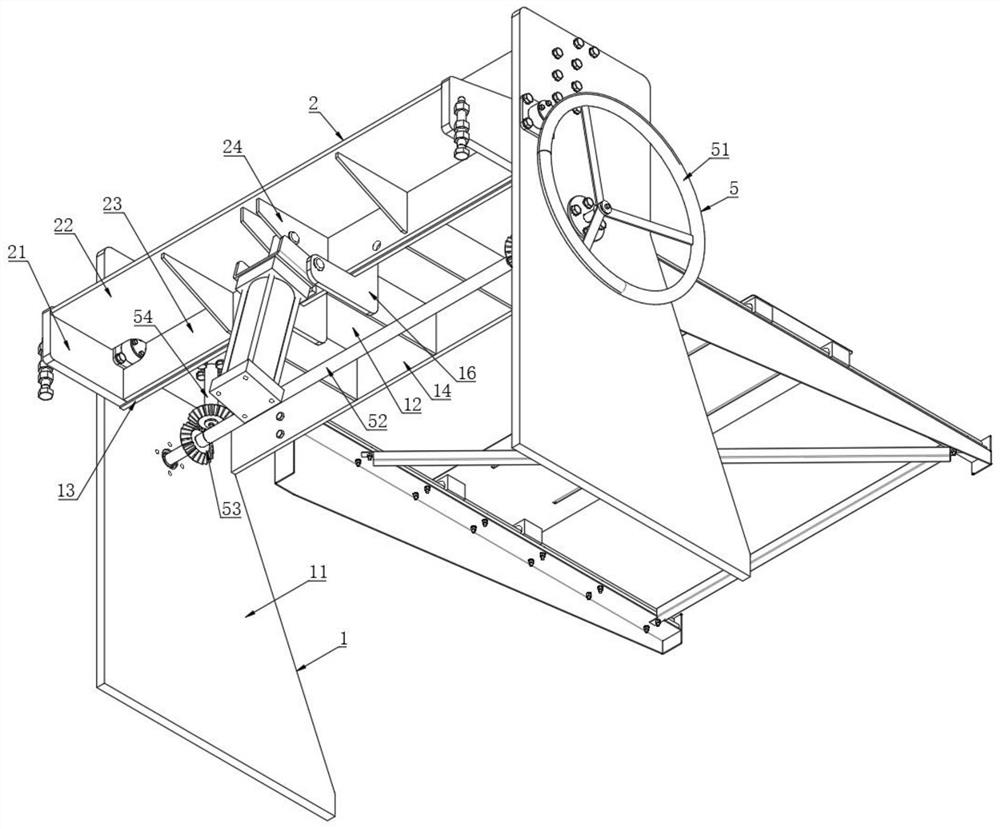

[0026] see Figure 1~5 , in an embodiment of the present invention, a long U-shaped metal plate bending equipment includes a fixed table 1, a rotary table 2, a pressing table 4 and a manual pressing mechanism 5; the fixed table 1 includes two vertically arranged Side plates 11, a horizontal fixed platen 12 is fixedly connected between the side plates 11, and a front vertical plate 13 and a rear vertical plate 14 are respectively fixedly connected to the front and rear sides of the bottom of the fixed platen 12; The bottom of the platen 12 is also fixedly provided with some reinforcing ribs fixedly connected with the front vertical plate 13 and the rear vertical plate 14 to ensure the connection strength between the front vertical plate 13 and the rear vertical plate 14 and the fixed platen 12; The bottom of the plate 12 is also fixedly connected with a cylinder fixed plate 16, and the other end of the cylinder fixed plate 16 is rotatably equipped with a cylinder 3;

[0027] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com