Plastic mold capable of cutting off excess materials and screening out defective products

A technology for plastic molds and defective products, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc. The effect of energy waste, convenient and fast process, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

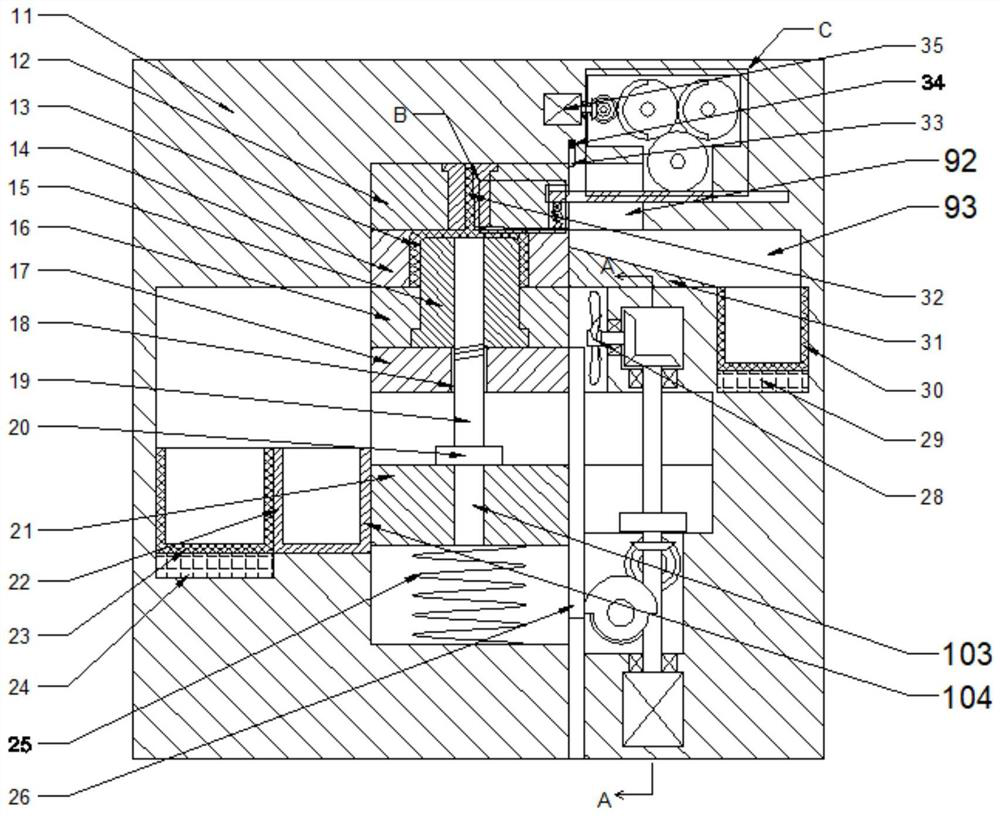

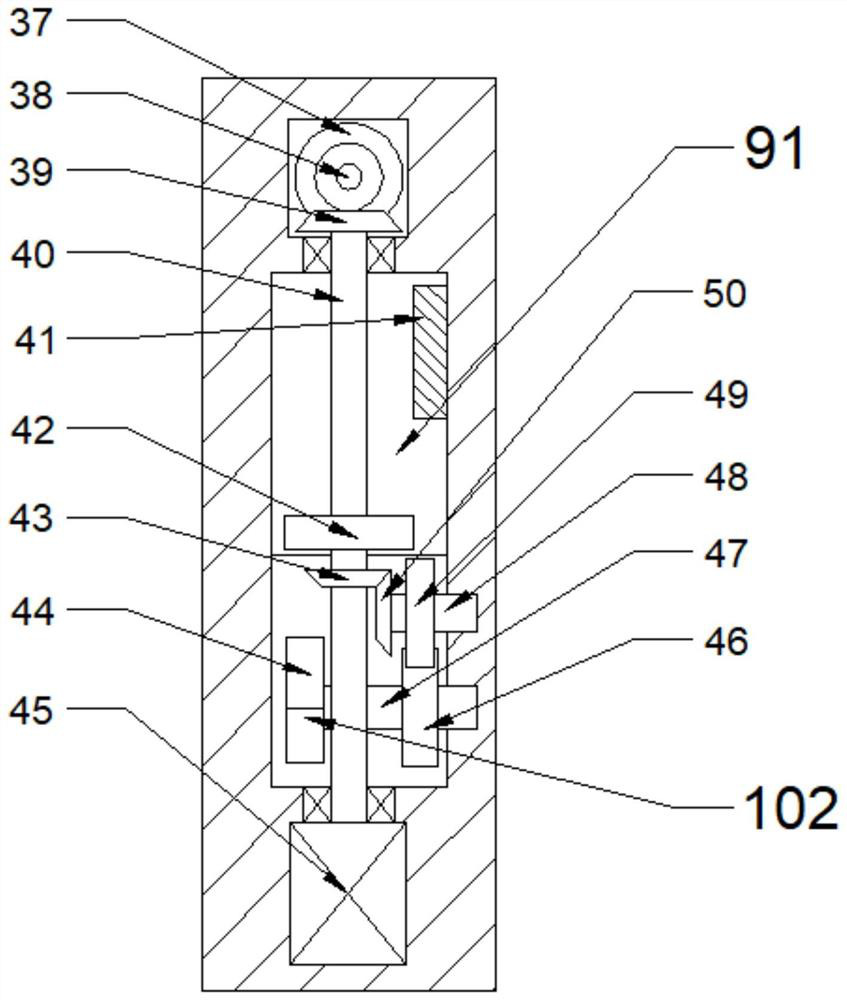

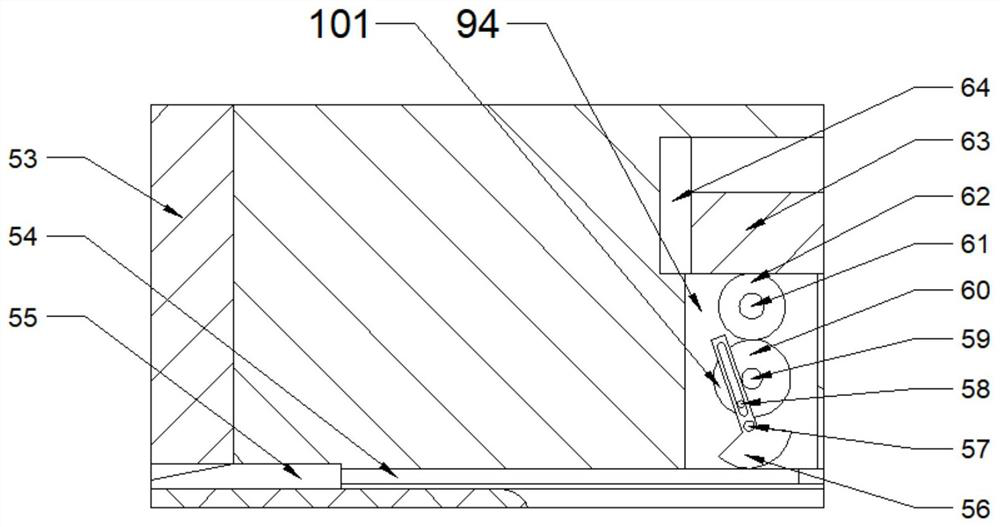

[0016] By below Figure 1-4 The present invention will be described in detail, in which it is convenient, the orientation of the following statements are shown below: figure 1 The projection relationship of the projection is consistent with the front and back and so on.

[0017] Join Figure 1-4 One remaining material is removed and the plastic mold of the deseel screen, including the body 11 and the right side of the body 11, and the top of the body 11 are provided with sliding The chamber 92 is provided with a slip chamber 93 in the body 11, and the sliding cavity 92 is provided with a rotary cavity 94 on the left side of the slide master 12, and the slide mother die 12 can slide left and right. The disposed in the upper portion of the body 11 is fixedly provided with an injection block 53, and the injection block 53 has a remaining material 32, and the sliding master 12 is on the rotation cavity 94. The setting with double-sided racks 63 can be slid around, and the double-sided r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com