Efficient bottom blowing method for improving steelmaking flow field in converter blowing

A converter blowing and high-efficiency technology, which is applied to the improvement of process efficiency and the manufacture of converters, etc., can solve the problems of prolonging the mixing time, disorderly flow of molten steel in the horizontal direction, and poor uniformity of molten steel, so as to improve processing efficiency and reduce Bottom blowing blind area, reducing the effect of mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

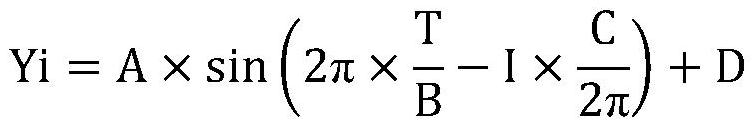

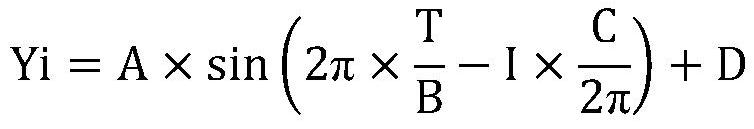

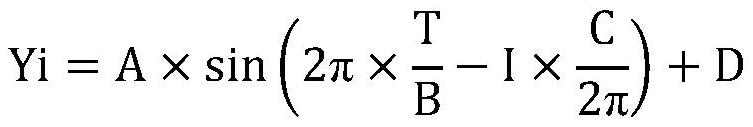

[0029] A high-efficiency bottom blowing method for improving the steelmaking flow field in converter blowing. Eight air supply units are installed at the bottom of the converter. The air supply units are diffused air-permeable bricks, and the eight air-permeable bricks are symmetrical to the center line of the converter trunnion Axis, symmetrically distributed at the bottom of the converter; eight air-permeable bricks start to blow in a clockwise order, and the air flow of a single air-permeable brick meets the change law of a sinusoidal curve;

[0030] In the bottom blowing method, nitrogen and argon are respectively blown into the converter, nitrogen is blown in during the first 85% of the total blowing time, and argon is blown in during the last 15% of the total blowing time;

[0031] When this embodiment is used to produce low-carbon steel, the total blowing time is 45 minutes, and all air-permeable bricks are sprayed in a cycle according to the formula, and the time of one...

Embodiment 2

[0042] The difference from Example 1 is that when used in the production of high carbon steel, in order to avoid the low carbon content at the end point, reduce the total gas volume of bottom blowing, and control the real-time total gas flow rate of bottom blowing of all air supply units to 0.04m 3 / (min t).

[0043] Using the method of the present invention, in the converter blowing process, the degree of mixing of molten steel is improved; the purity of molten steel is increased (carbon-oxygen product is reduced from 0.00253 to 0.00195), effectively improving product quality; the average smelting time of molten steel is reduced by 33S, Calculated on the average reduction of half a minute for each furnace of steel, 3 furnaces of 900 tons more can be produced per month, and the annual output can be increased by 10,800 tons. Calculated based on the benefit of 200 yuan per ton of steel, the annual benefit can be increased by 2.16 million yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com