Inertia type instrument closed structure internal recycling cleaning device

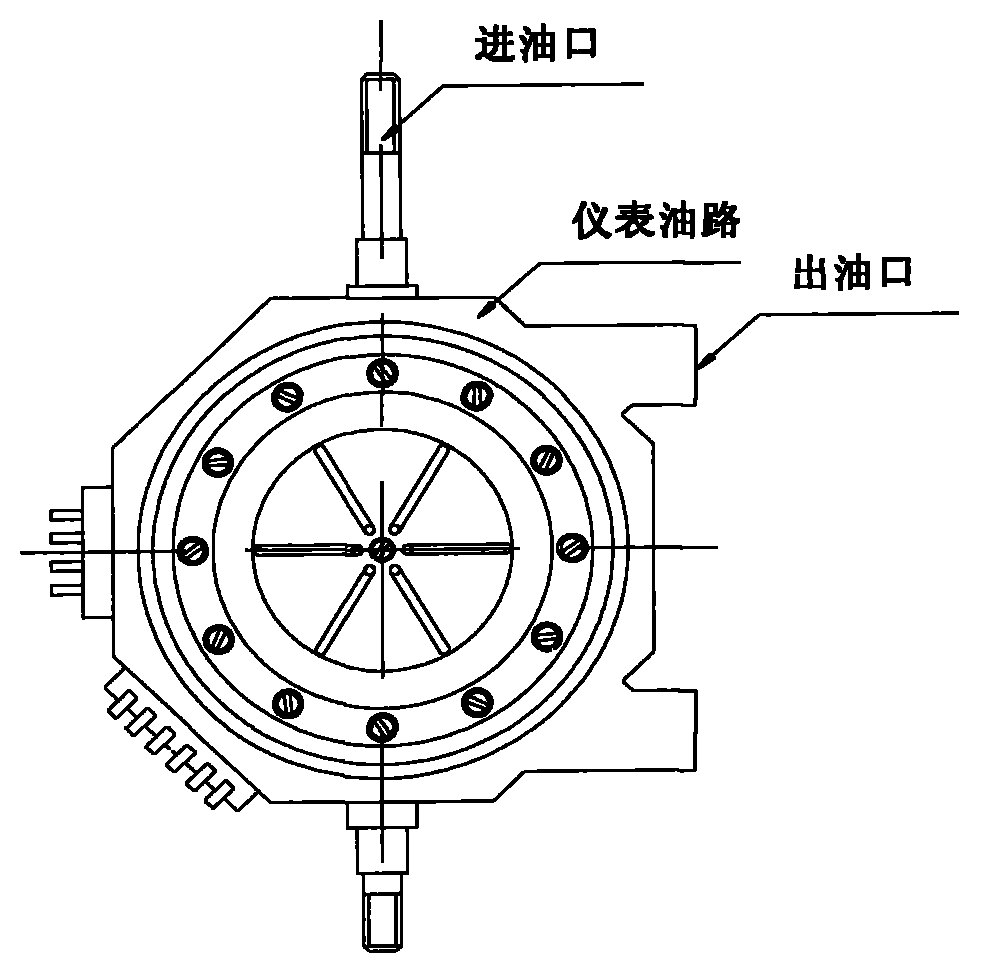

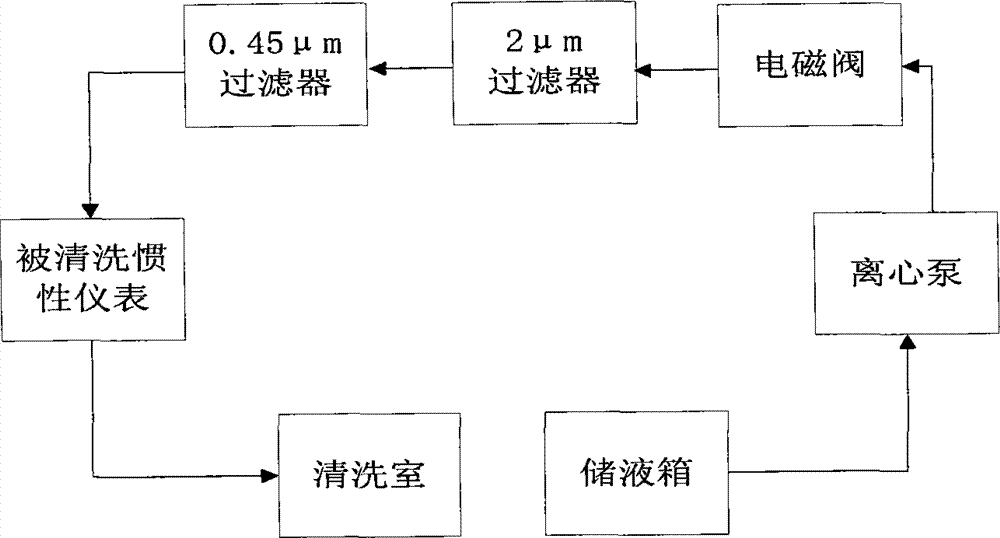

A technology for inertial instruments and cleaning equipment, which is applied in the field of cleaning equipment and internal circulation cleaning equipment for the airtight structure of inertial instruments. It can solve the problems of incomplete cleaning and large particles, and achieve the effect of diversifying cleaning methods and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

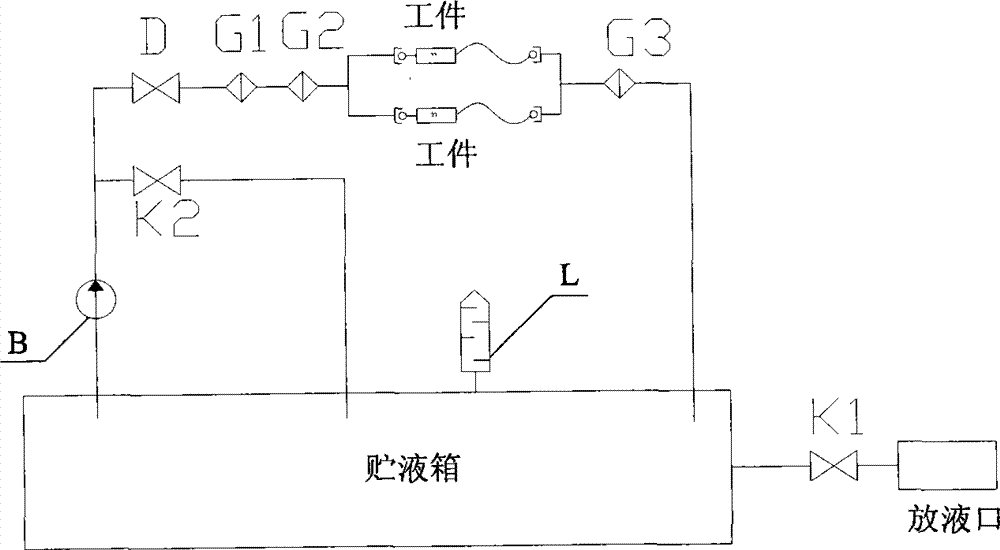

[0025] Example 1: Open cleaning method

[0026] Such as image 3 As shown, the oil inlet of the gyro assembly is connected after the second filter G2, the oil outlet of the gyro assembly is disconnected from the third filter G3, and the sealing cover of the gyro assembly at one end is opened to make it an open structure, and the The gyro assembly is placed in a clean container. Set the cleaning time, turn on the centrifugal pump, and start the open cleaning. After cleaning, take out 100ml of cleaning solution, filter it through filter paper into a clean container, check that there are no particles larger than 2 microns on the surface of the filter paper under an ultra-depth-of-field microscope, and repeat the cleaning until there are no particles larger than 2 microns on the filter paper, and determine the final cleaning time.

Embodiment 2

[0027] Example 2: Closed pulse cycle cleaning method

[0028] The pulse solenoid valve is connected in series between the oil inlet of the gyro assembly and the second filter G2, the oil outlet of the gyro assembly is connected to the third filter G3, and the cleaning times and cleaning frequency are set such as pulse width 2s, controlled by the controller The switch of the pulse solenoid valve can realize the alternate operation of continuous cycle cleaning and pulse cycle cleaning. After cleaning, install process plugs at the oil inlet and outlet of the gyro assembly to prevent pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com