Self-adjusting double-layer road guardrail

A highway guardrail and self-adjusting technology, which is applied in the direction of roads, roads, road safety devices, etc., can solve the problems of reducing the service life of guardrails, general buffering effect, poor buffering effect, etc., and achieve the effect of convenient transportation and saving space for transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

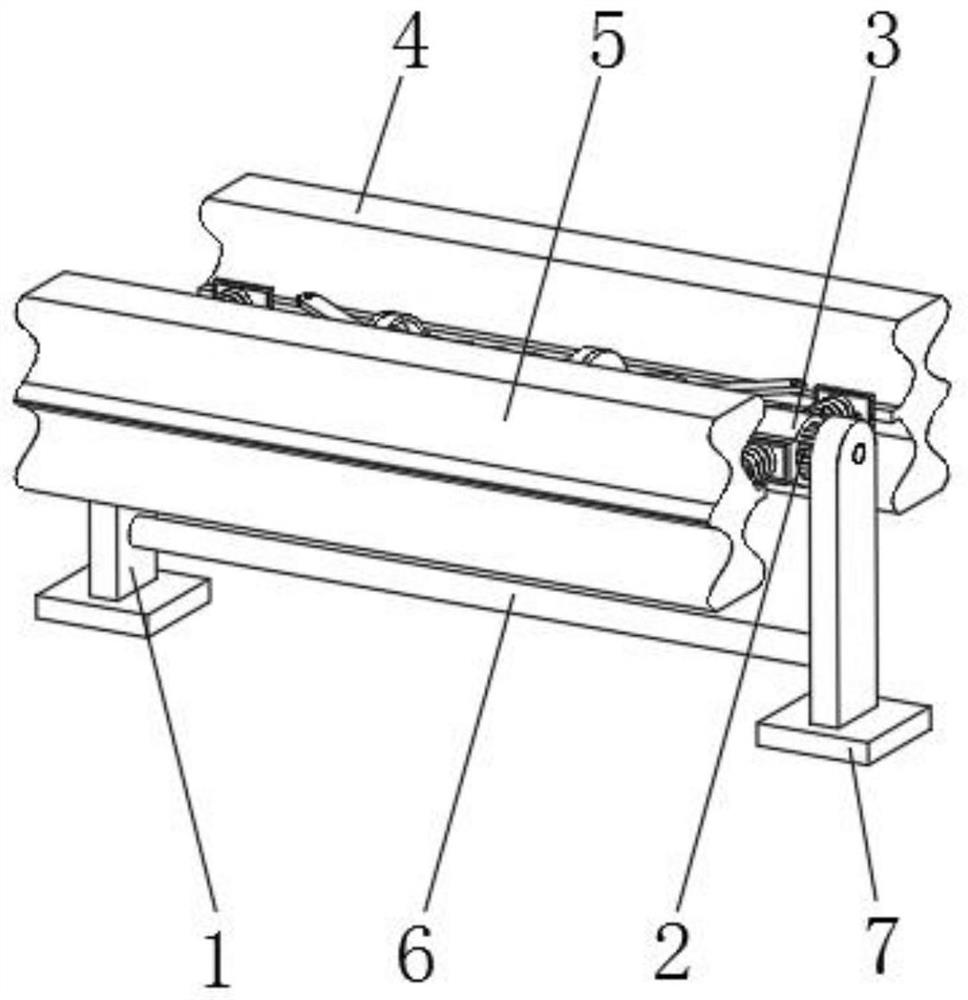

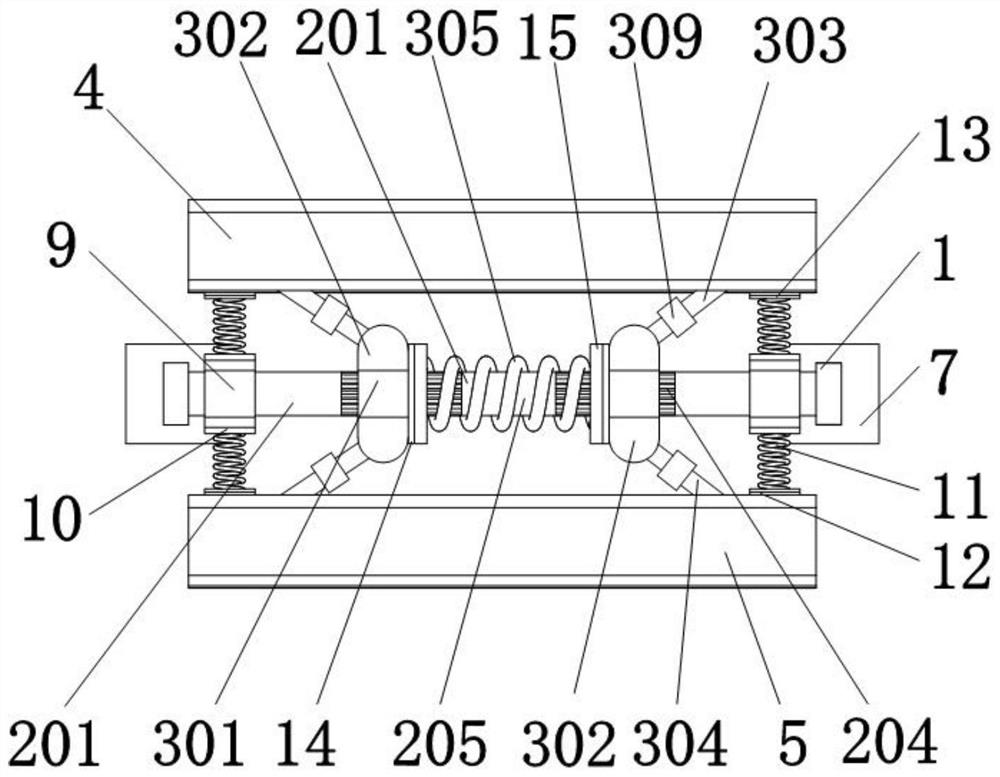

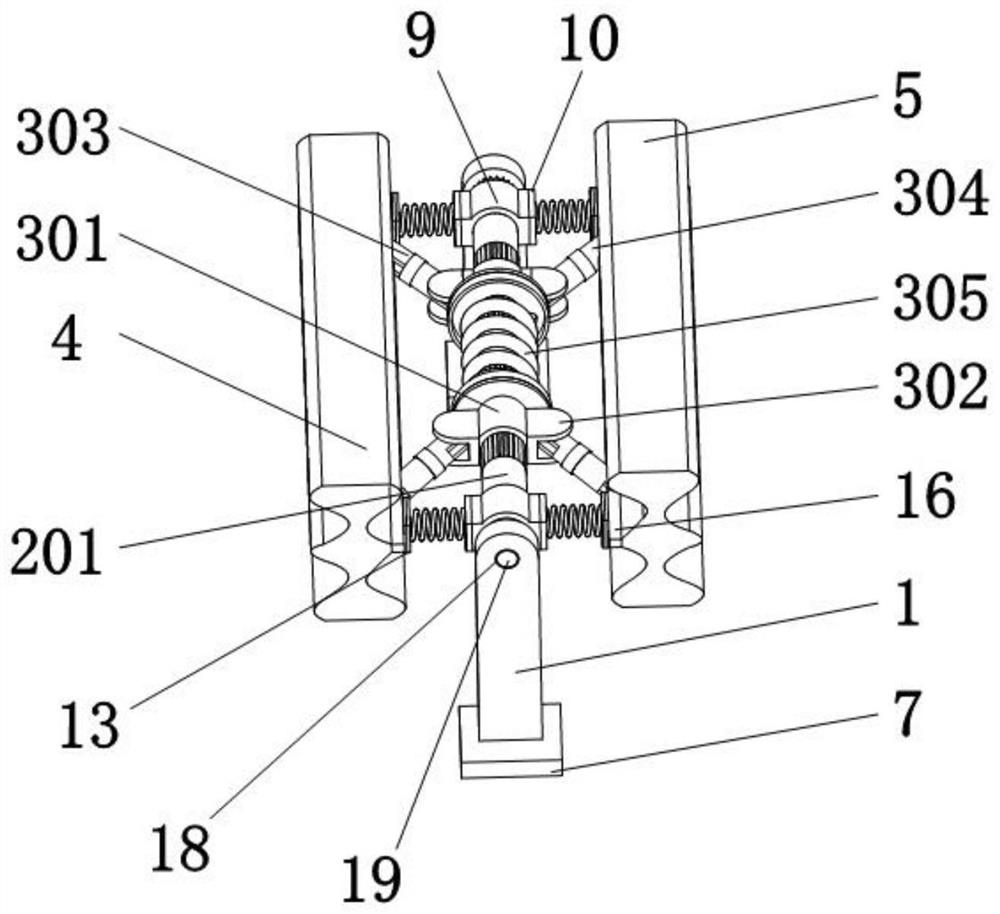

[0028] Such as Figure 1 to Figure 5 As shown, the present invention provides a self-adjusting double-deck road guardrail, comprising a support frame 1; wherein the number of support frames 1 is two, and a fixed rod 6 is fixedly connected between the facing surfaces of the two support frames 1, and the two support frames 1 are fixedly connected with each other. The bottoms of each support frame 1 are fixedly connected with a base 7, and the stability of the guardrail after installation and use can be greatly improved due to the setting of the fixed rod 6.

[0029] A connecting part 2 is fixedly installed on the side of the support frame 1, and the connecting part 2 includes a sliding rod 201, and both ends of the sliding rod 201 are connected to the side of the supporting frame 1; the sliding rod 201 is divided into a sliding area 204 and a smooth area 205, A shock-absorbing part 3 is provided on the sliding area 204; when the device is in normal use, the sliding sleeve 301 of...

Embodiment 2

[0041] After the impact occurs, when one of the first guardrail 4 and the second guardrail 5 is deformed and cannot be repaired in time, but the device still needs to be used for safety protection, the first guardrail 4 and the second guardrail 5 are squeezed by the return spring 11. Make the first guardrail 4 and the second guardrail 5 close to the sliding rod 201; when the two are close to the sliding rod 201, squeeze the two sliding sleeves 301 through the first connecting rod 303 and the second connecting rod 304, so that The two sliding sleeves 301 approach each other and squeeze the shock absorbing spring 305; when the shock absorbing spring 305 is squeezed to a certain extent, the two sliding sleeves 301 break away from the sliding area 204 and move to the smooth surface on the sliding rod 201. zone 205; at this time, by squeezing the first guardrail 4 and the second guardrail 5, the two sliding sleeves 301 are kept on the basis of the smooth zone 205, so that the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com