Fixed-torque connecting piece anti-knock buffering combined screw

A technology for fixing torque and connecting parts. It is applied in the direction of connecting components, screws, and threaded fasteners. It can solve the problems that screws do not have anti-vibration buffers, the torque of screws is not easy to control, and objects or screws are damaged by shocks, so as to increase the torque. , The effect of preventing falling off and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

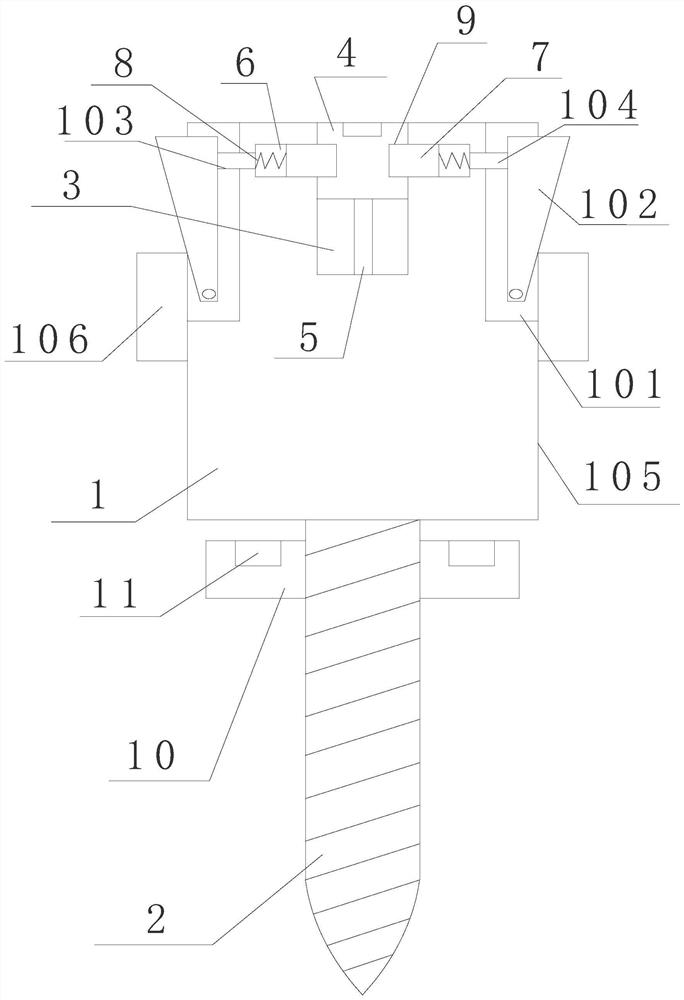

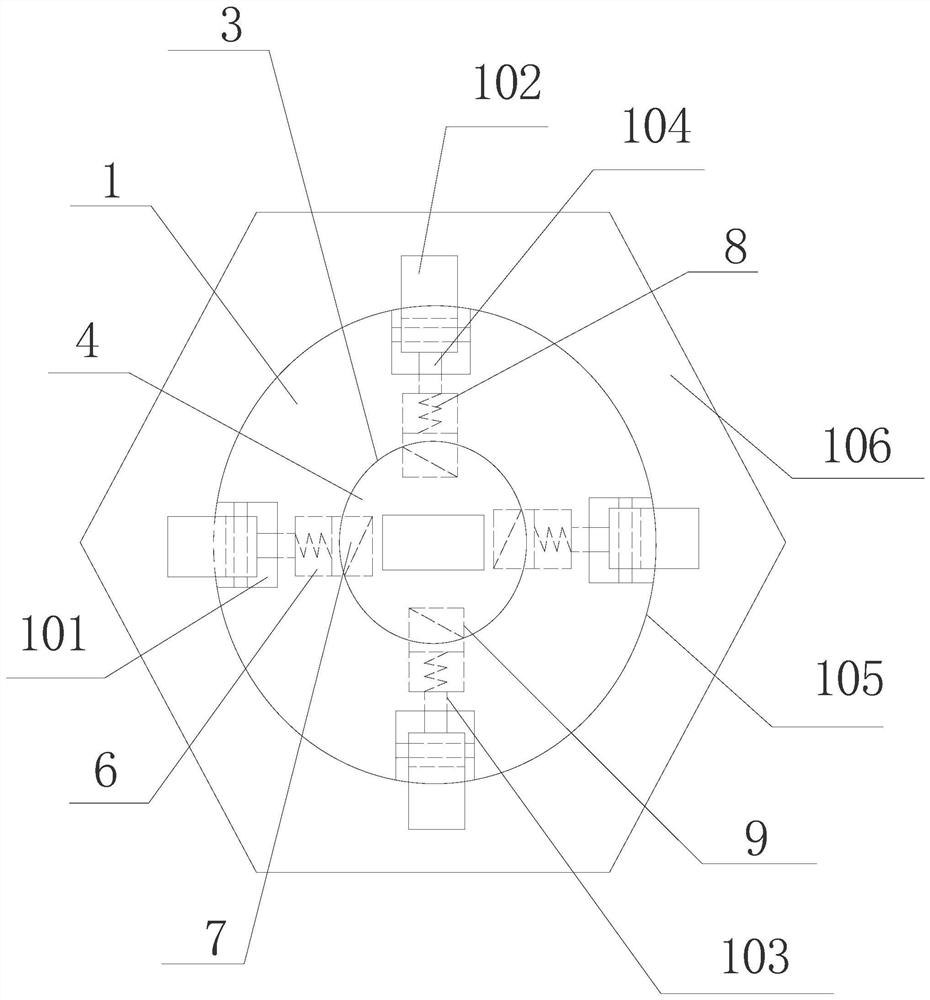

[0015] refer to figure 1 , 2 , the present invention is an anti-seismic buffer combination screw for a fixed torque connector, including a nail head 1, a nail rod 2, a mounting hole 3, a twisting block 4, a connecting rod 5, a limiting hole 6, a limiting rod 7, a spring 8, Jack 9, elastic gasket 10 and magnet block 11, the bottom of described nail head 1 is fixedly provided with nail rod 2, and the center position of the top of described nail head 1 offers mounting hole 3, can be installed in described mounting hole 3 Rotation is provided with twisting block 4, and the central position of the hole bottom of described mounting hole 3 can be rotated and is provided with connecting rod 5, and the upper end of described connecting rod 5 is connected with twisting block 4 in rotation, and the inner side wall of described mounting hole 3 A plurality of limiting holes 6 distributed along the radial direction of the nail head 1 are evenly opened, and a limiting rod 7 can be slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com