Waterproof wall bushing for basement exterior wall and mounting method of waterproof wall bushing

A technology for basement exterior wall and wall-penetrating casing, which is applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc. Problems such as wall casing damage, to achieve excellent waterproof effect, excellent waterproof effect, and ensure the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

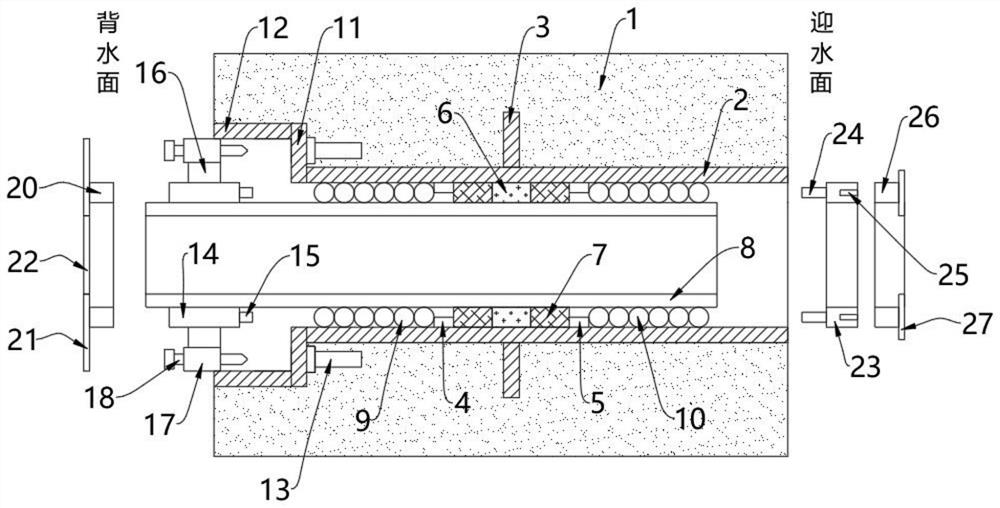

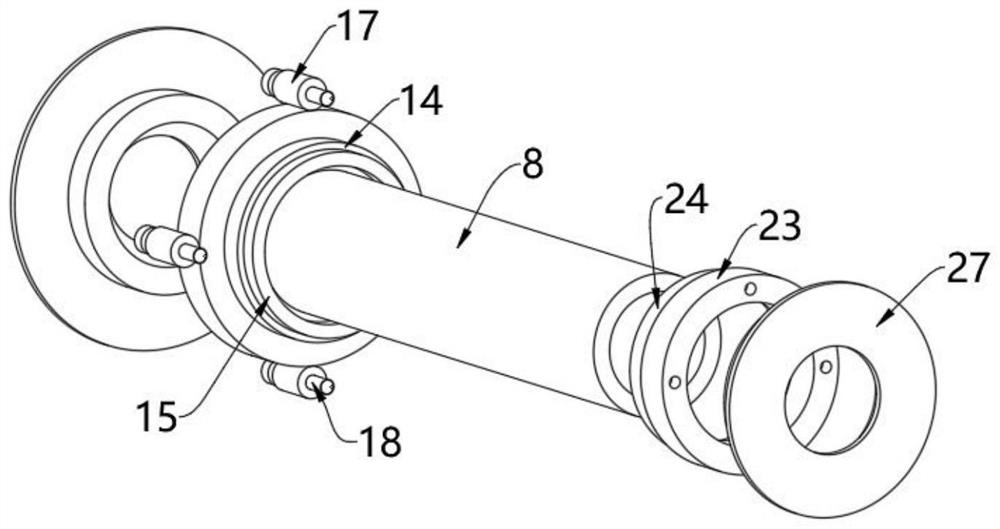

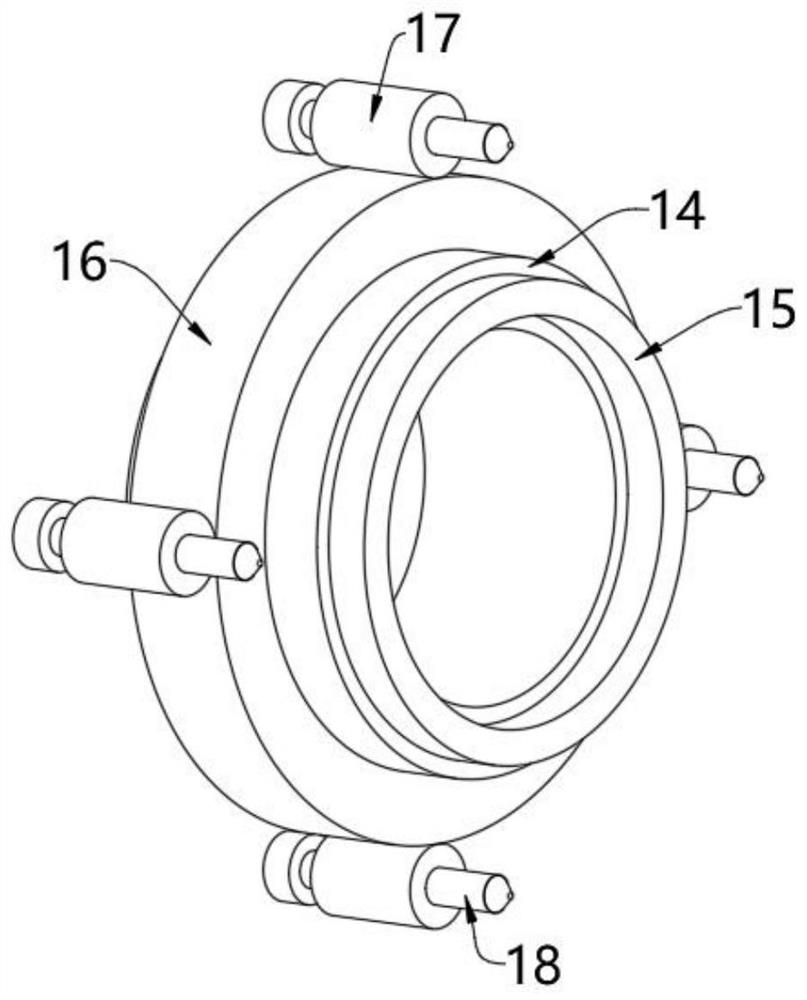

[0047] see Figure 1-Figure 4 , a waterproof wall-piercing casing for the exterior wall of a basement, comprising an exterior wall 1 and a flexible waterproof casing 2 pre-embedded inside the exterior wall 1, the middle of the outer wall of the flexible waterproof casing 2 is provided with a water-stop ring 3, flexible and waterproof A flange 11 is fixedly installed on the end of the casing 2 facing the backwater surface, and a mounting cylinder 12 is fixedly installed on the edge of the outer wall of the flange 11 facing the backwater side, and the outer wall of the flange 11 facing the waterfront side is uniformly fixed and installed There are threaded sleeves 13;

[0048] The interior of the flexible waterproof casing 2 is plugged with a wall-piercing pipe 8, and the outer wall of the end of the wall-piercing pipe 8 located at the backwater surface is fixedly equipped with a fixing ring 14, and a locking mechanism connected between the threaded sleeve 13 and the fixing ring...

Embodiment 2

[0054] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 , on the basis of Embodiment 1, a left retaining ring 4 and a right retaining ring 5 are respectively fixedly installed on both sides of the inner wall of the flexible waterproof casing 2, and an elastic damping ring is fixedly installed between the left retaining ring 4 and the right retaining ring 5 7 and the elastic sound-insulating ring 6, the elastic vibration-damping ring 7 and the elastic sound-insulating ring 6 are provided with three altogether, wherein the elastic sound-insulating ring 6 is arranged in the middle, and the elastic vibration-damping ring 7 is arranged on both sides of the elastic sound-insulating ring 6, and the elastic vibration-damping ring 7 is used for shock absorption, and the elastic sound insulation ring 6 is used for sound insulation. The left retaining ring 4 is fixedly installed with several left gaskets 9 on the side facing the backwater surface, and the right retaining ...

Embodiment 3

[0060] see Figure 1-Figure 7 , on the basis of Embodiment 1 and Embodiment 2, a method for installing a waterproof wall-penetrating sleeve for the basement exterior wall is proposed, including the following steps:

[0061] Step 1: Select a flexible waterproof casing 2 of appropriate size, and weld the flexible waterproof casing 2 to the fixed steel bar of the outer wall 1;

[0062] Step 2: Place a nail-shaped water bag 29 inside the flexible waterproof casing 2 to temporarily support the flexible waterproof casing 2; fix and install templates 30 at both ends of the flexible waterproof casing 2, and temporarily close the flexible waterproof casing 2;

[0063] Step 3: Pour the wall concrete according to the standard construction requirements and wait for it to solidify;

[0064] Step 4: After the wall concrete is solidified, remove the formwork 30 at both ends of the flexible waterproof casing 2 and take out the nail-shaped water bag 29;

[0065] Step 5: Insert the wall-pierc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com