Front-drive type electric vehicle energy recovery torque calibration method

A technology of braking energy recovery and energy recovery, applied in electric vehicles, control drive, power management, etc., can solve the problems of unanalyzed and imperfect constraints of front-wheel drive vehicles, shorten the calibration period, and reduce the frequency of activating ABS. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

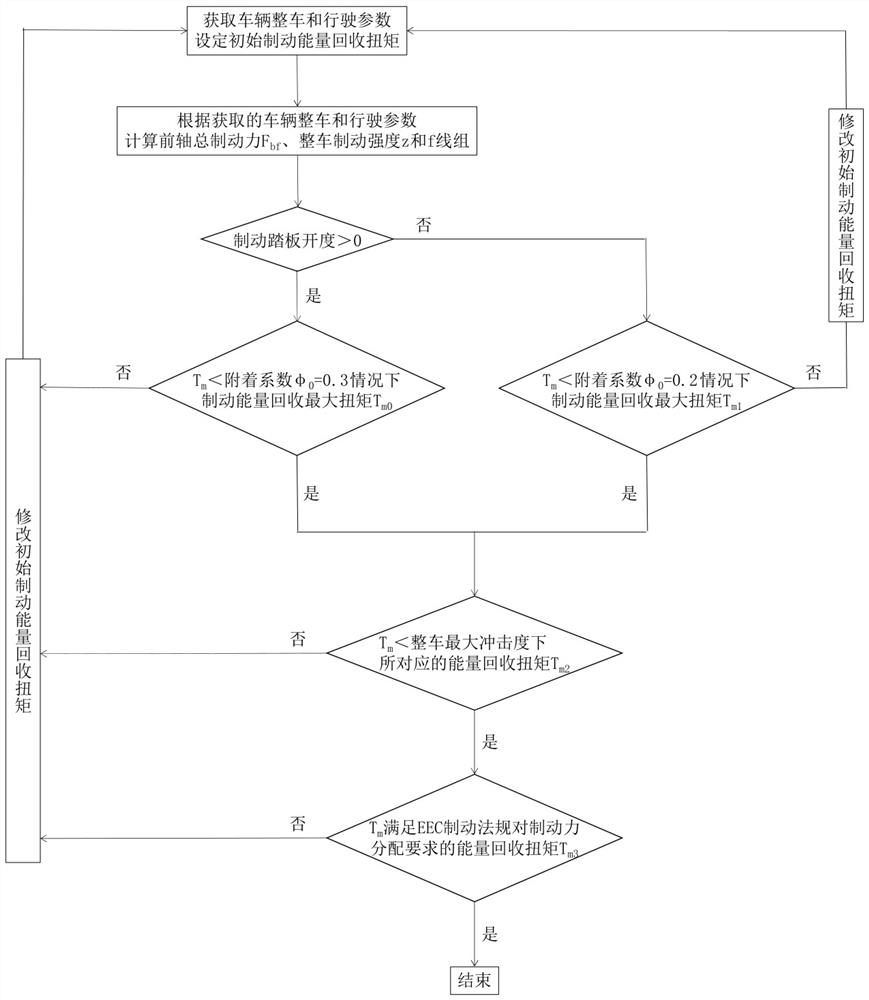

[0037] Example: see figure 1 .

[0038] Such as figure 1 As shown, a method for calibrating energy recovery torque of a front-drive electric vehicle of the present invention comprises the following steps:

[0039] Step 1. According to the dynamic properties of the vehicle and the aerodynamic test to obtain the vehicle and driving parameters, set the initial braking energy recovery torque T m ;

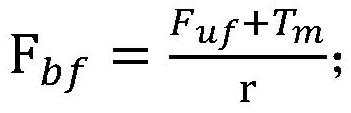

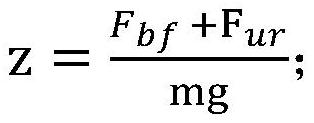

[0040] Step 2. According to the vehicle and driving parameters obtained in step 1, calculate the total braking force F of the front axle at each speed range under different brake pedal openings bf , vehicle braking strength z and f line group;

[0041] Step 3. Confirm the brake pedal opening, when the brake pedal opening = 0, go to step 4; when the brake pedal opening > 0, go to step 5;

[0042] Step 4. According to the f line group obtained in step 2, calculate the road surface adhesion coefficient φ 0 = 0.2 braking energy recovery maximum torque T m0 , if the initial braking e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com