Urban rail vehicle brake cylinder pressure control method and system

A brake cylinder pressure and control method technology, applied in the direction of brakes, vehicle components, pneumatic brakes, etc., can solve the problems of long pressure response lag time, pressure exceeding precision, and affecting the service life of valves, so as to reduce the difficulty of control and reduce The number of valve operations and the effect of improving control reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

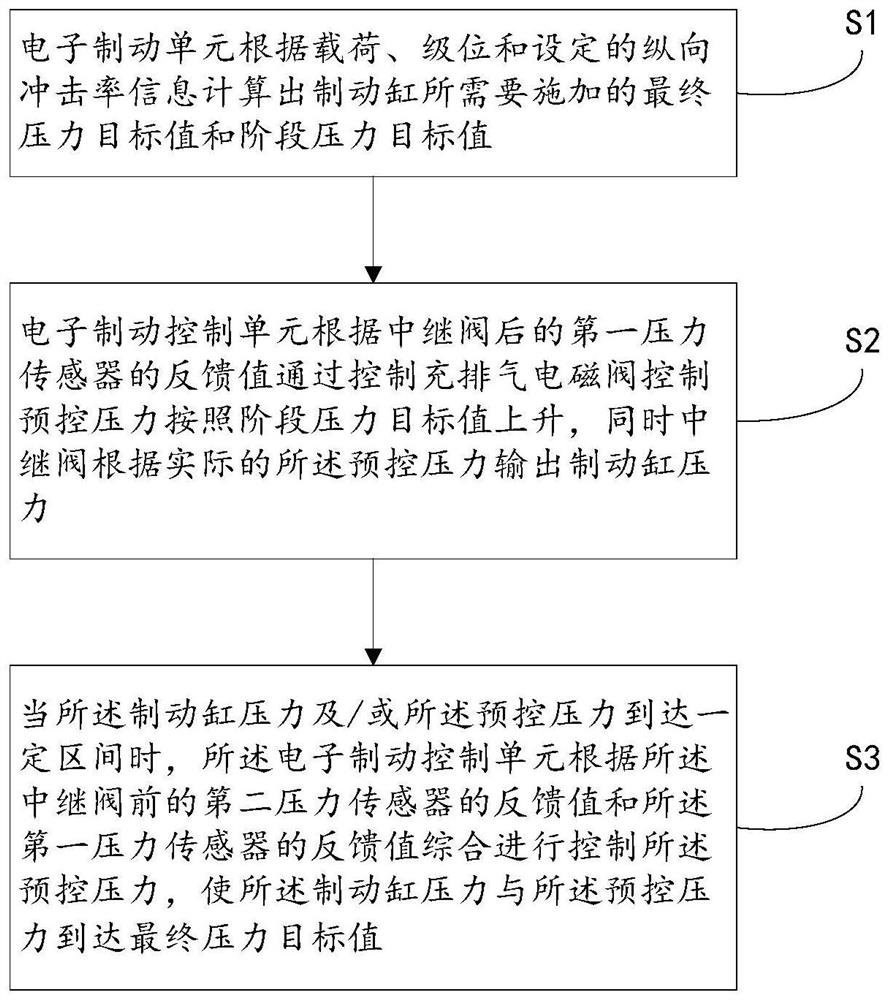

[0052] Such as figure 1 As shown, this embodiment discloses a specific implementation of a brake cylinder pressure control method for an urban rail vehicle (hereinafter referred to as "method").

[0053] Specifically, the method disclosed in this embodiment mainly includes the following steps:

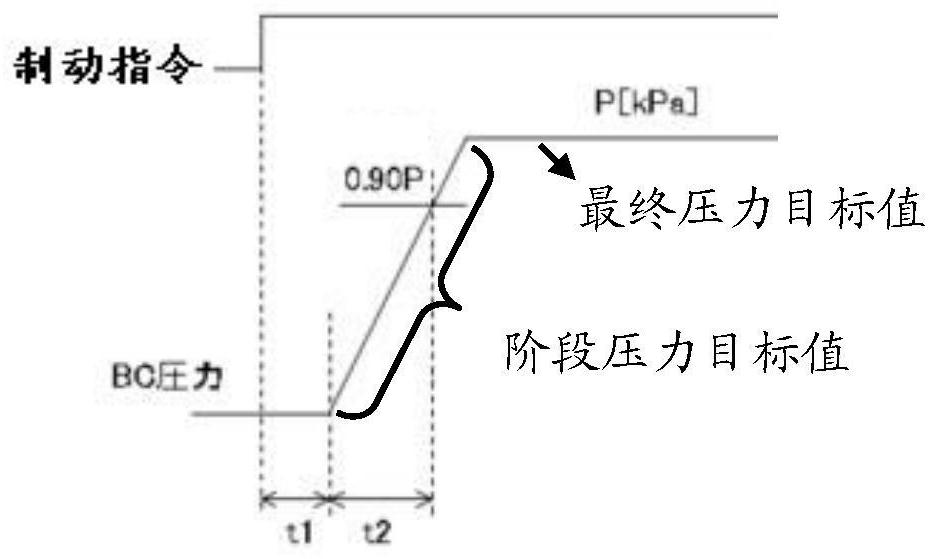

[0054] Step S1: The electronic brake control unit calculates the final pressure target value and stage pressure target value required by the brake cylinder according to the load, level and the set longitudinal impact rate information;

[0055] Step S2: According to the feedback value of the first pressure sensor behind the relay valve, the electronic brake control unit controls the pre-control pressure to rise according to the stage pressure target value by controlling the charging and exhaust solenoid valve, and the relay valve is based on the actual pre-control pressure. The pressure outputs the brake cylinder pressure; wherein, the first pressure sensor collects the brake cylinder ...

Embodiment 2

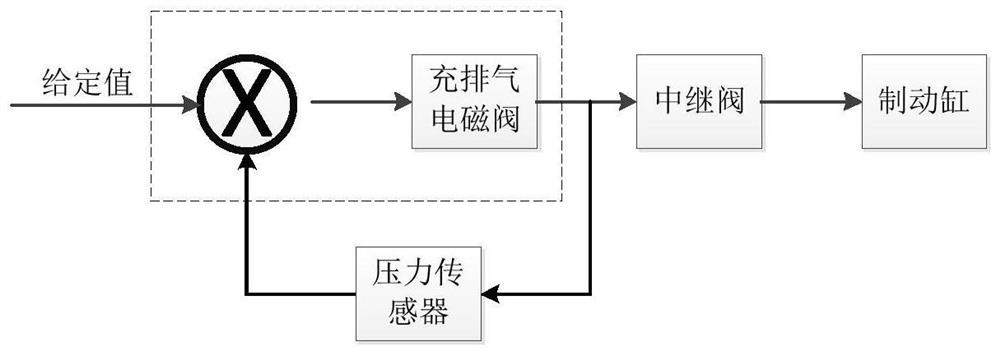

[0084] In combination with the brake cylinder pressure control method for urban rail vehicles disclosed in Embodiment 1, this embodiment discloses a specific implementation example of a brake cylinder pressure control system for urban rail vehicles (hereinafter referred to as "system").

[0085] The system includes:

[0086] Electronic brake control unit: Calculate the final pressure target value and stage pressure target value that the brake cylinder needs to apply according to the load, level and set longitudinal impact rate information;

[0087] The first pressure sensor: used to feed back the pressure value of the brake cylinder behind the relay valve to the electronic brake control unit;

[0088] The second pressure sensor: used to feed back the pre-control pressure value before the relay valve to the electronic brake control unit;

[0089] Filling and exhausting solenoid valve: used to convert the compressed air output of the air storage cylinder into the pre-control pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com