Molding equipment for solid tyres

A technology for forming equipment and solid tires, applied to tires, other household appliances, household appliances, etc., can solve the problems of low production efficiency, easy layering of tires, easy deviation of rubber strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

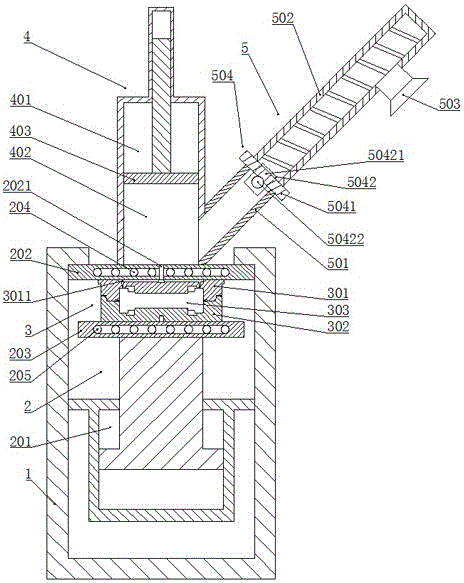

[0017] exist figure 1 Among them, a solid tire molding equipment, which includes a frame 1, a mold 3, a clamping device 2, a material injection device 4 and a material delivery device 5.

[0018] The mold clamping device 2 is used for mold opening and mold closing of the mold 3 . like figure 1 As shown, it includes a first hydraulic cylinder 201 , an upper heating plate 202 and a lower heating plate 203 . Wherein, the upper heating plate 202 is fixed on the upper part of the frame 1 through bolt connection, the first hydraulic cylinder 201 is assembled on the bottom of the frame 1 , and the lower heating plate 203 is fixed on the piston rod of the first hydraulic cylinder 201 . In order to meet the molding needs of rubber materials, such as figure 1 As shown, the upper heating plate 202 and the lower heating plate 203 are respectively provided with a first heating element 204 and a second heating element 205 .

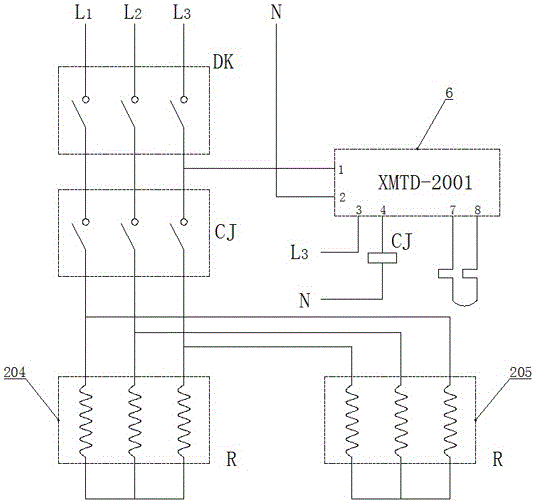

[0019] The first heating element 204 and the second heating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com