Ytterbium-doped optical fiber, preform and preparation method thereof

A technology of ytterbium-doped optical fiber and preform, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of irregular optical fiber profile, irregular core rod profile, and reduce the volatility of P2O5, so as to ensure the refractive index profile and increase the doping Effect of impurity efficiency and improvement of darkening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

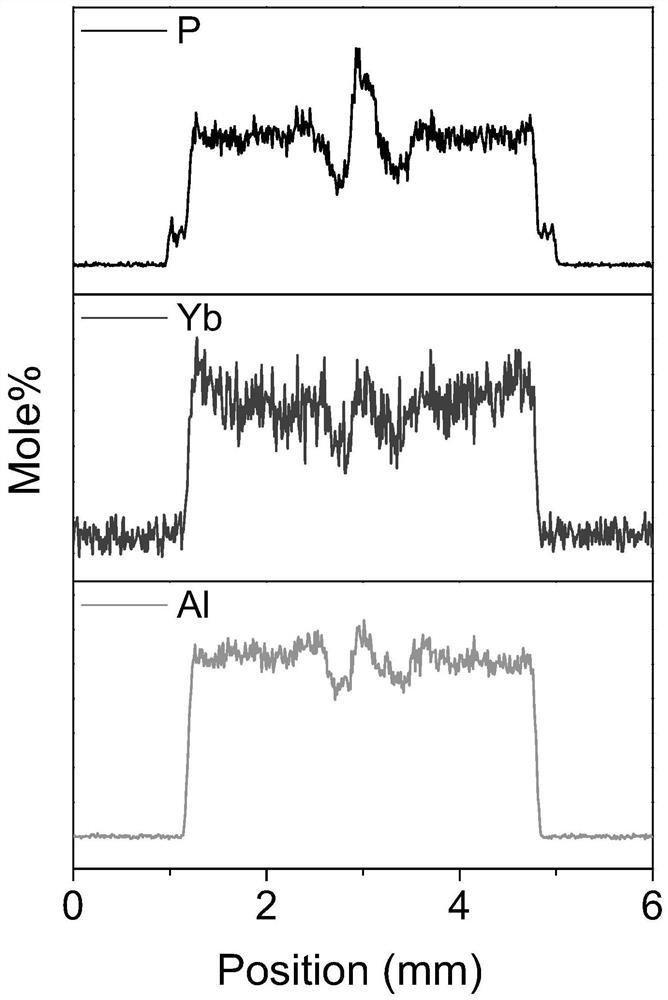

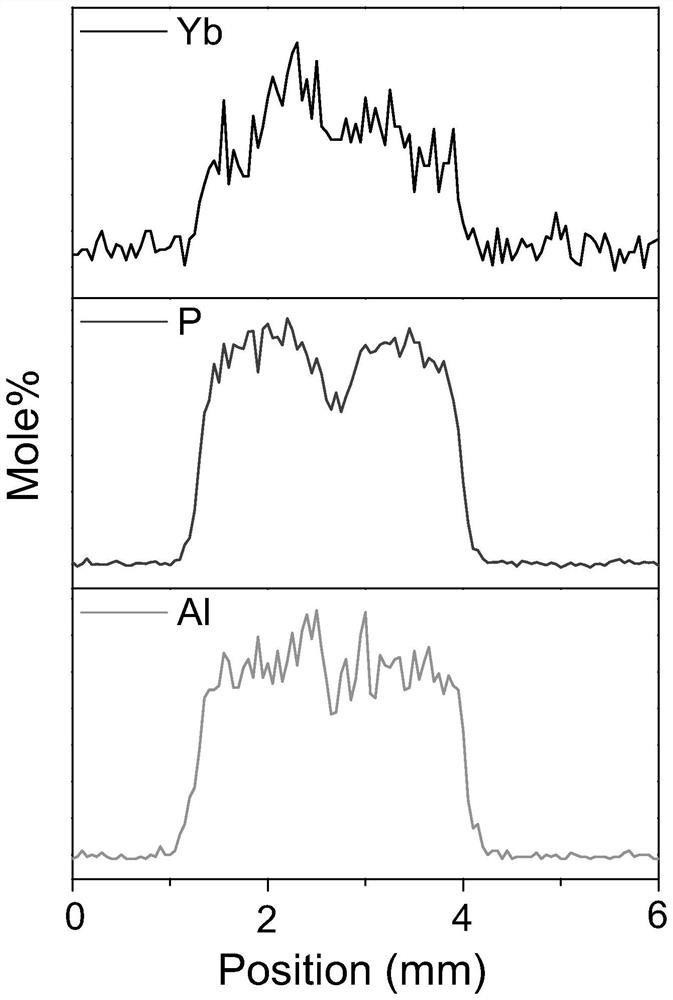

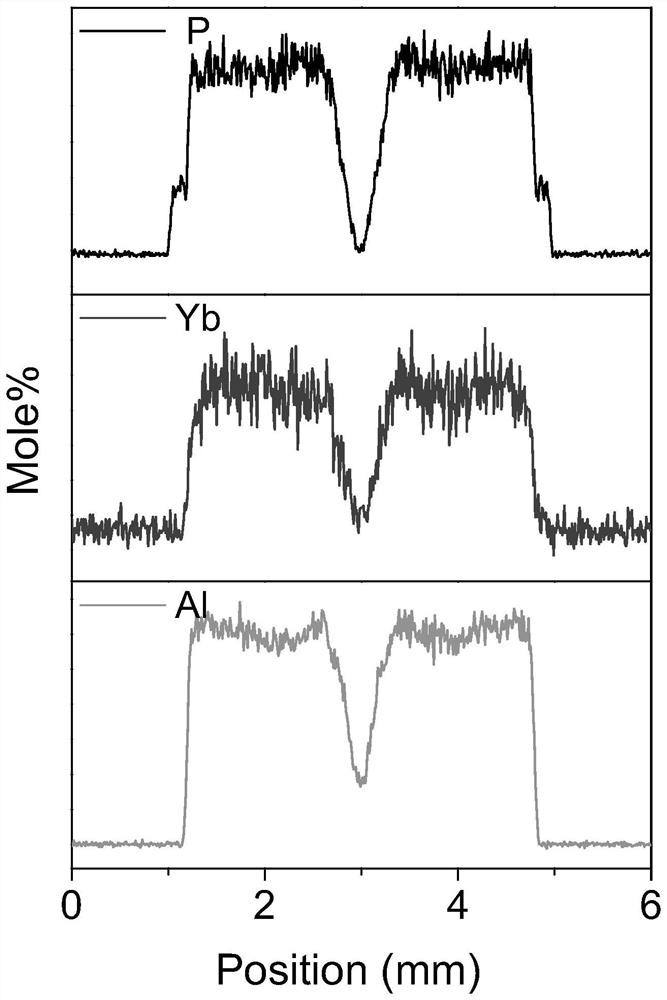

[0035] The invention provides a method for preparing an ytterbium-doped optical fiber preform. The purpose of the method is to improve the element distribution uniformity of the section of the ytterbium-doped optical fiber preform, so as to effectively ensure the smoothness of the section refractive index. The present invention reduces the concentration difference of P2O5 in the liner in the shrinkage stage by injecting POCl3 during the shrinkage, thereby reducing the volatility of P2O5, and can effectively solve the problem of irregular cross-section of mandrel rods in high phosphorus-doped systems, but excessive or slight deposition of P2O5 , will also lead to irregular optical fiber profiles, so it is necessary to have exact requirements for melting temperature, pressure, time, POCl3 flow rate, etc. This method specifically includes the following steps:

[0036] S1: Deposition of a doped silica layer within a quartz liner comprising:

[0037] Using the MCVD vapor deposition...

Embodiment 1

[0052] S1: Fix the pure quartz glass liner with the specifications of 30mm (outer diameter)*3mm (wall thickness)*750mm (tube length) on the MCVD lathe, first deposit Si+P+F outer cladding, the deposition temperature is 2000°C, The flow rate of O2 is 1200sccm, the flow rate of SiCl4 is 500sccm, the flow rate of POCl3 is 150sccm, and the flow rate of C2F6 is 10sccm. After the outer cladding is deposited, the inner cladding is deposited at a deposition temperature of 1900°C. The flow rate of C2F6 is 4 sccm, the carrier gas flow rate of Yb(thmd)3 is 300 sccm, and the carrier gas flow rate of AlCl3 is 100 sccm. According to the designed core diameter, 30 layers are deposited repeatedly;

[0053] S2: After the deposition is completed, enter the melting and shrinking stage, the moving speed of the main lamp is 150mm / min, the flow rate of H2 is 70slm, the flow rate of H2 is 35slm, the pressure is 80Pa, and POCl3 is introduced and deposited in the forward direction (the moving direction...

Embodiment 2

[0056] S1: Fix the pure quartz glass liner with the specifications of 30mm (outer diameter)*3mm (wall thickness)*750mm (tube length) on the MCVD lathe, first deposit Si+P+F outer cladding, the deposition temperature is 2000°C, The flow rate of O2 is 1200sccm, the flow rate of SiCl4 is 500sccm, the flow rate of POCl3 is 150sccm, and the flow rate of C2F6 is 10sccm. After the outer cladding is deposited, the inner cladding is deposited at a deposition temperature of 1900°C. The flow rate of C2F6 is 4 sccm, the carrier gas flow rate of Yb(thmd)3 is 300 sccm, and the carrier gas flow rate of AlCl3 is 100 sccm. According to the designed core diameter, 30 layers are deposited repeatedly;

[0057] S2: After the deposition is completed, enter the melting and shrinking stage, the moving speed of the main lamp is 150mm / min, the flow rate of H2 is 70slm, the flow rate of H2 is 35slm, the pressure is 80Pa, and POCl3 is introduced and deposited in reverse (the moving direction of the main l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com