Nutrition pot sprout grafting machine

A seedling grafting and nutrition bowl technology, applied in the field of automatic grafting devices, can solve the problems that the specifications and sizes of the nutrition bowl are not uniform, the space occupied by the workbench is large, and the quality of grafting is affected, so as to avoid multiple movements, simple structure, The effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

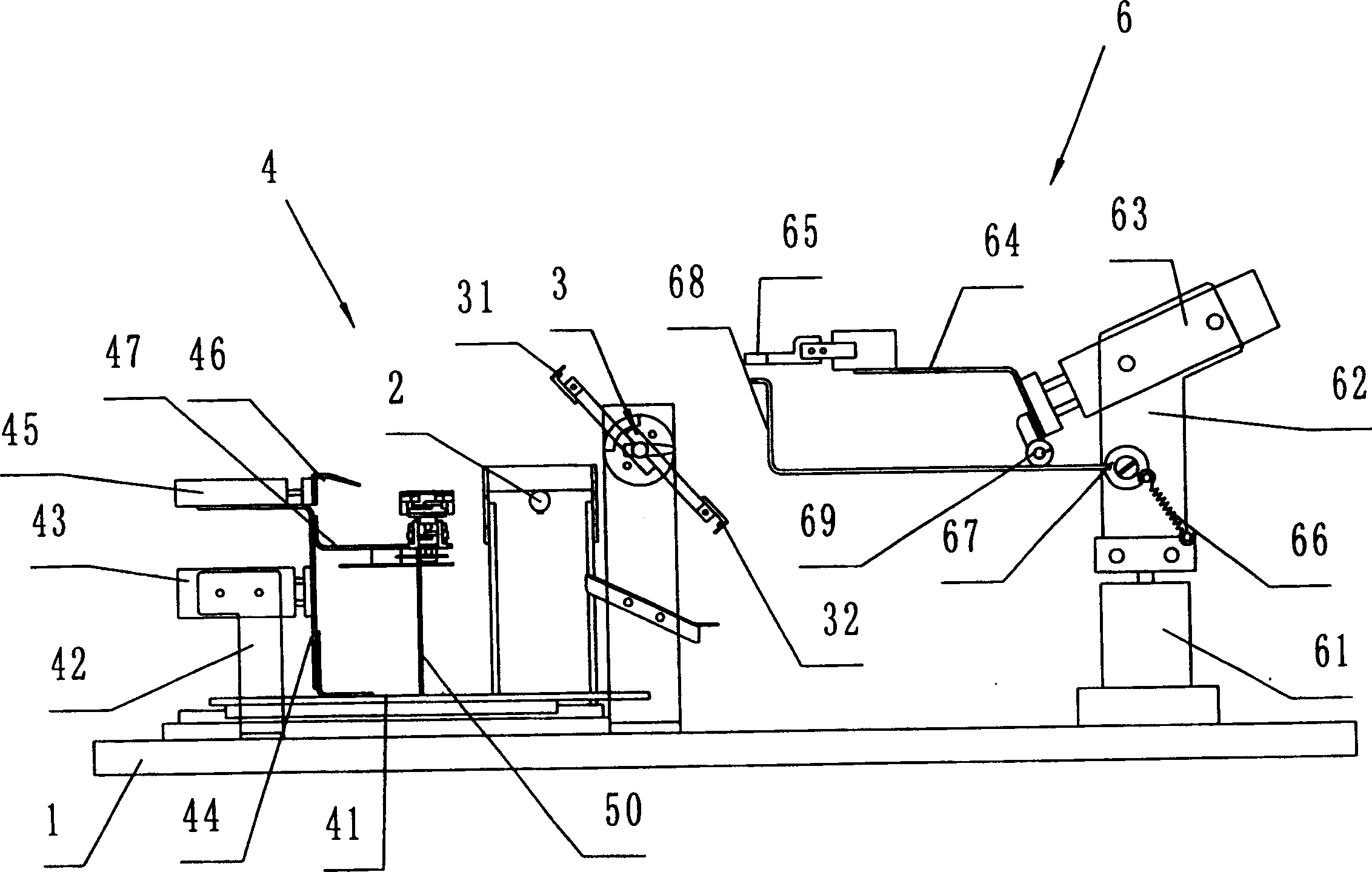

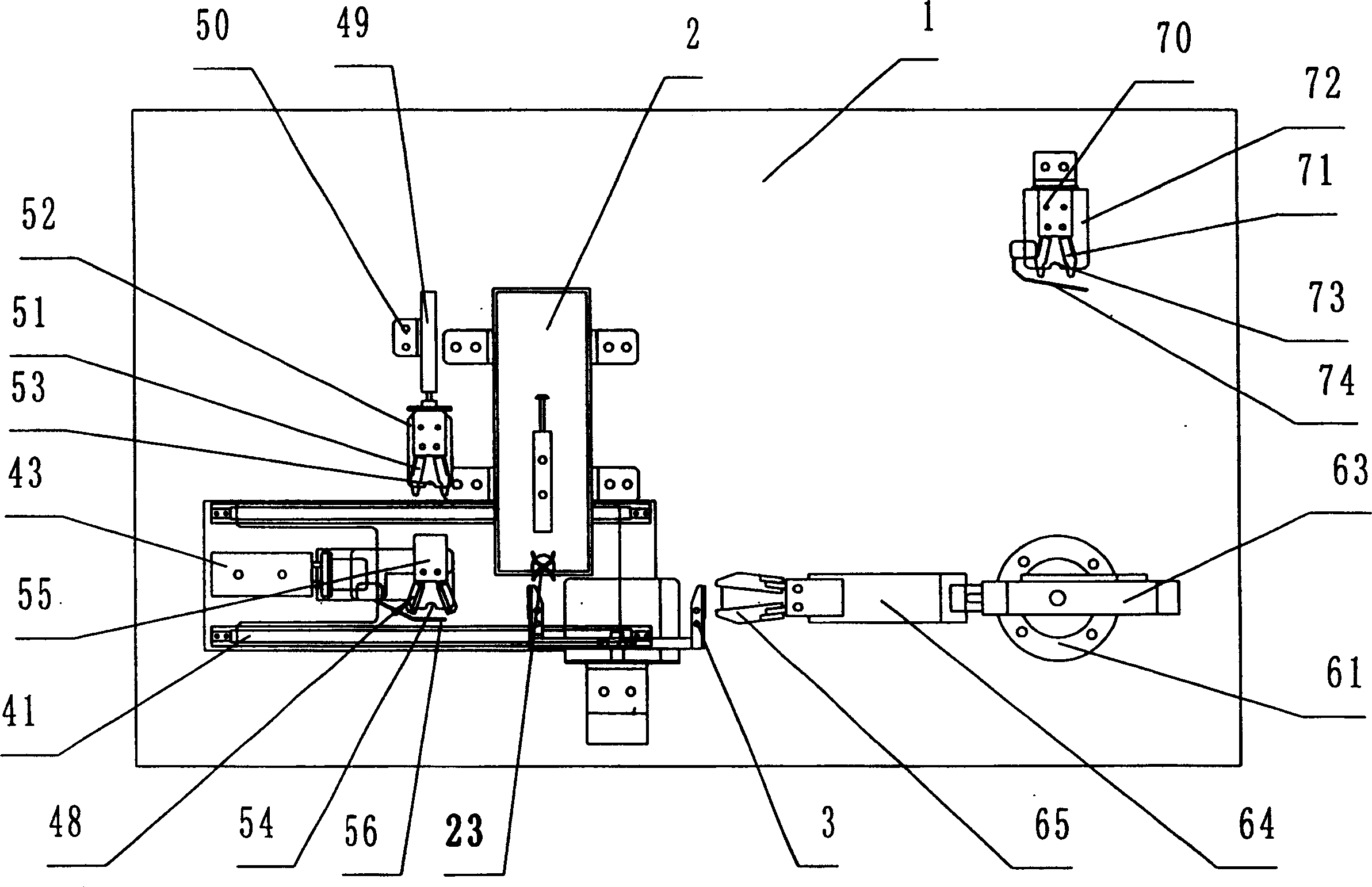

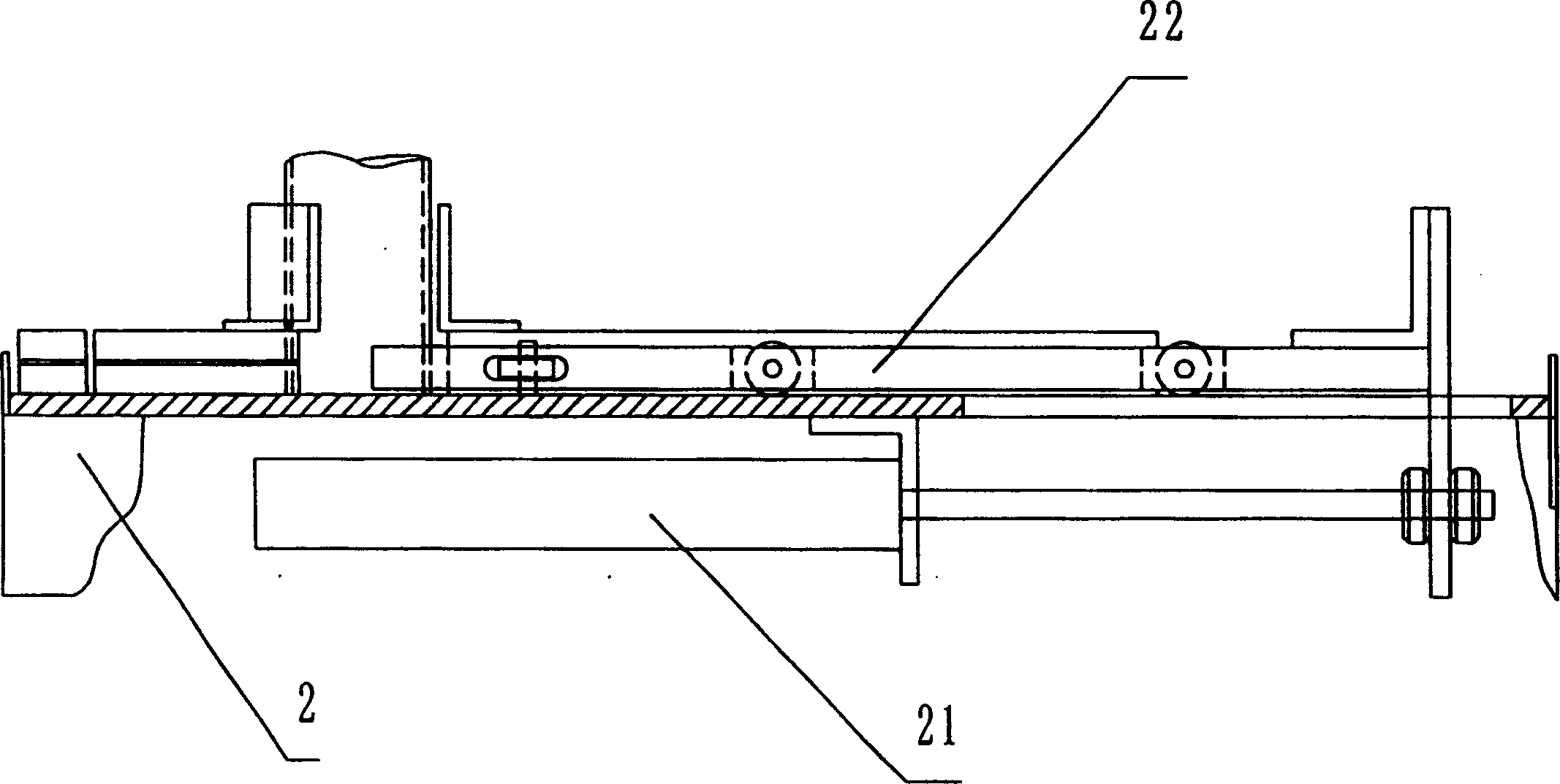

[0014] like figure 1 , figure 2 As shown, the present invention includes an operating platform 1, a clamp feeder 2 is arranged at the middle and rear part of the operating platform 1, a seedling cutting cutter head 3 is opposite to it and staggered to the right by a certain distance, and a rootstock is transported at the left part of the operating platform. Device 4, the right part of the console is the spike wood handling device 6.

[0015] like figure 1 , figure 2 As shown, the rootstock handling device 4 includes two transverse slide rails 41 arranged on the console 1 and positioned at the front of the clamp feeder 2, and a bracket 42 fixed on the console 1 is arranged between the two slide rails 41. A stock delivery cylinder 43 is installed on the 42. A Z-shaped plate 44 is connected on the piston of the stock delivery cylinder 43, and the bottom of the Z-shaped plate 44 is slidably arranged on two slide rails 41. The top of the Z-shaped plate 44 is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com