Folding type membrane electrode plate packaging assembly and manufacturing method thereof

A manufacturing method and membrane electrode technology, applied to special packaging objects, packaging objects under special gas conditions, packaging, etc., can solve problems such as deformation, loss, and damage to membrane electrode plates, and achieve simple and convenient operation, safe packaging, and improved The effect of production accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

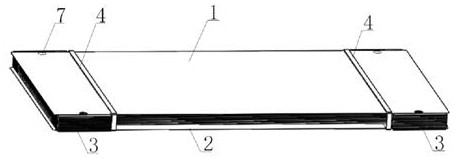

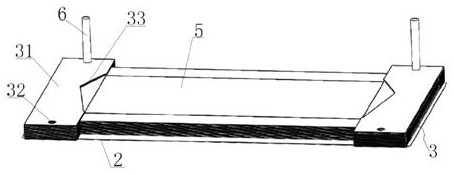

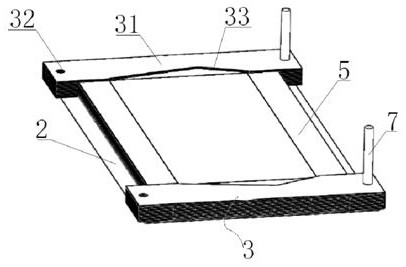

[0036] refer to figure 1 , a foldable membrane electrode plate packaging assembly, which includes an upper platen 1, a lower platen 2, a side pad 3, and a rubber band 4. The side pad 3 is designed as two groups of left and right and the two groups of side pads 3 are installed symmetrically. The side pads 3 are correspondingly installed at the two ends between the upper platen 1 and the lower platen 2. The side pads 3 include several layers of spacers 31, and the outer sides of two adjacent spacers 31 are connected to each other. Openings are formed on the inner sides of the two adjacent spacers 31, and the two ends of several membrane electrode plates 5 are respectively inserted into the openings of the two adjacent spacers 31. fastened together to form a packaged assembly. The side pad is designed to fill the gap between the two ends of the membrane electrode plate through the spacer, and the outer side of the spacer is connected, which can wrap the end of the membrane elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap