Degradable adhesive tape and preparation method thereof

A technology for adhesive tape and preparation steps, which is applied in the field of degradable adhesive tape and its preparation, can solve the problems of non-environmental protection of adhesive tape, and achieve the effect of reducing white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

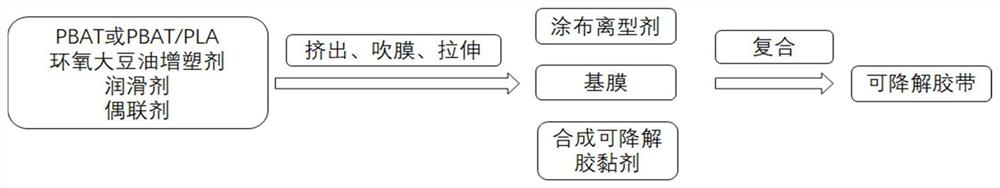

[0041] A preparation method of degradable adhesive tape, as follows:

[0042] 68 parts by weight of PBAT, 23 parts of PLA, 2 parts of plasticizer epoxy soybean oil, 0.5 part of lubricant stearic acid, 0.1 part of coupling agent titanate, twin-screw extrusion granulation at 165-175 ° C, 170 ℃ single-screw extrusion blown film, inflation ratio 4.0, draw ratio 30. The film is biaxially stretched. Stretching setting temperature is controlled at 60-70°C for longitudinal setting and 100-110°C for transverse setting.

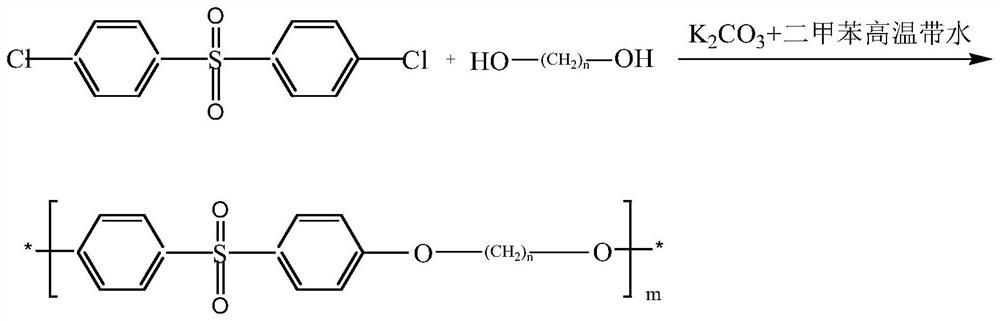

[0043] At the same time, weigh a certain amount of dichlorodiphenyl sulfone, place it in a 1L round-bottomed flask, add polyethylene glycol 400 in an equimolar amount of hydroxyl and dichlorodiphenyl sulfone, use thionyl chloride as a solvent, and xylene As a water-carrying agent, it was distilled in an oil bath at 160°C for 12 hours, and the product was precipitated in anhydrous ether. It was dissolved in N’N-dimethylformamide and purified by ether reprecipitation....

Embodiment 2

[0054] A preparation method of degradable adhesive tape, as follows:

[0055] 60 parts by weight of PBAT, 35 parts of PLA, 3 parts of plasticizer epoxy soybean oil, 0.8 part of lubricant stearic acid, 0.2 part of coupling agent titanate, twin-screw extrusion granulation at 170-180 ° C, 190 ℃ single-screw extrusion blown film, inflation ratio 4.5, draw ratio 33. The film is biaxially stretched. Stretching setting temperature is controlled at 65-70°C for longitudinal setting and 100-110°C for transverse setting.

[0056] At the same time, weigh a certain amount of dichlorodiphenyl sulfone, place it in a 1L round bottom flask, add polyethylene glycol 200 in an equimolar amount of hydroxyl and dichlorodiphenyl sulfone, use thionyl chloride as a solvent, and xylene As a water-carrying agent, it was distilled in an oil bath at 140°C for 10 hours, and the product was precipitated in anhydrous ether. It was dissolved in N’N-dimethylformamide and purified by ether reprecipitation. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap