Hydraulic coil pipe testing equipment

A technology for testing equipment and coils, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. It can solve problems such as pipe dryness, pipe rupture, and pipe bursting, so as to facilitate later use and improve safety. Sexuality, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

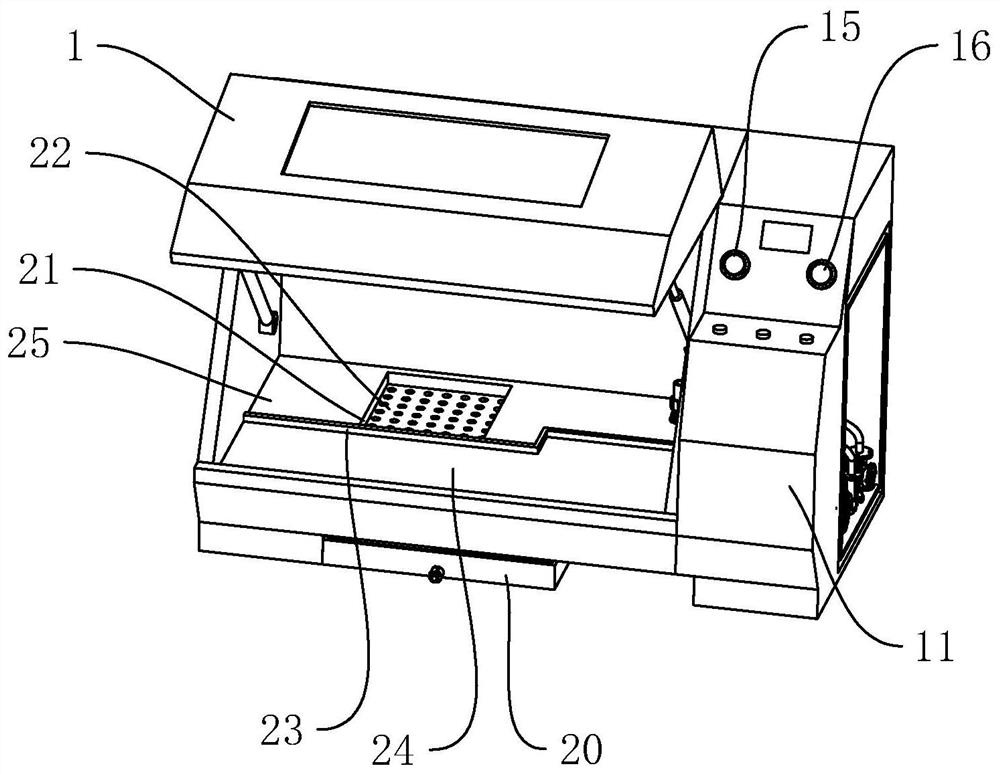

[0031] The following is attached Figure 1-4 The application is described in further detail.

[0032] The embodiment of the present application discloses a hydraulic coil testing device.

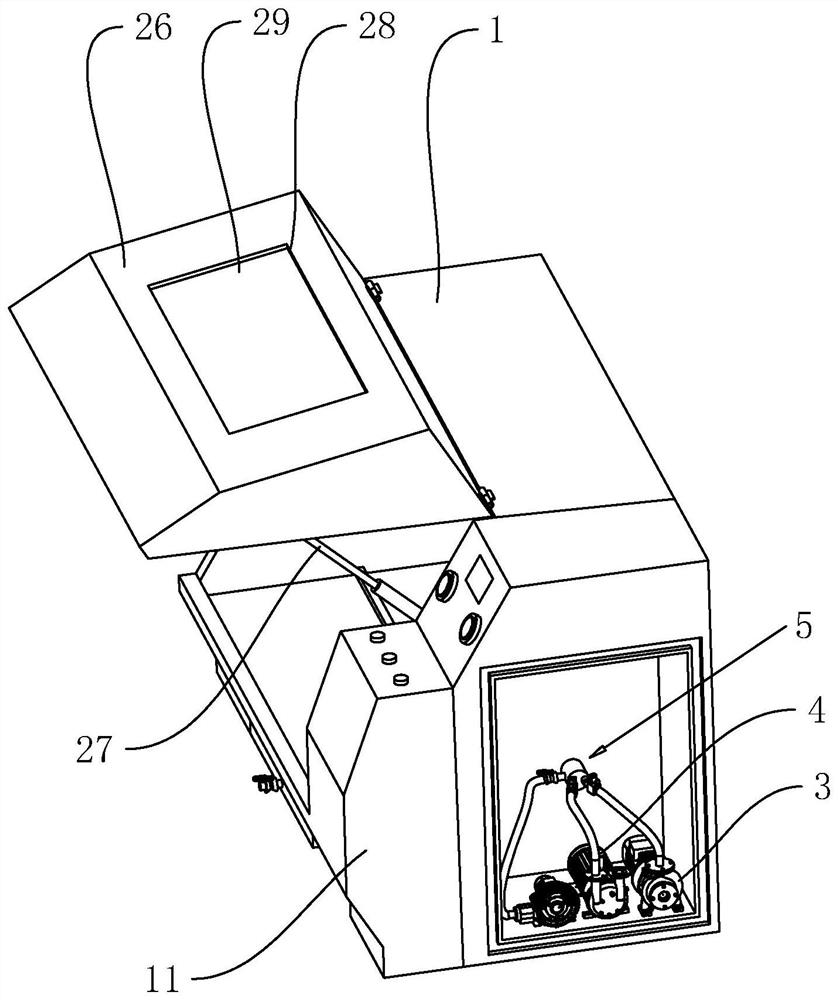

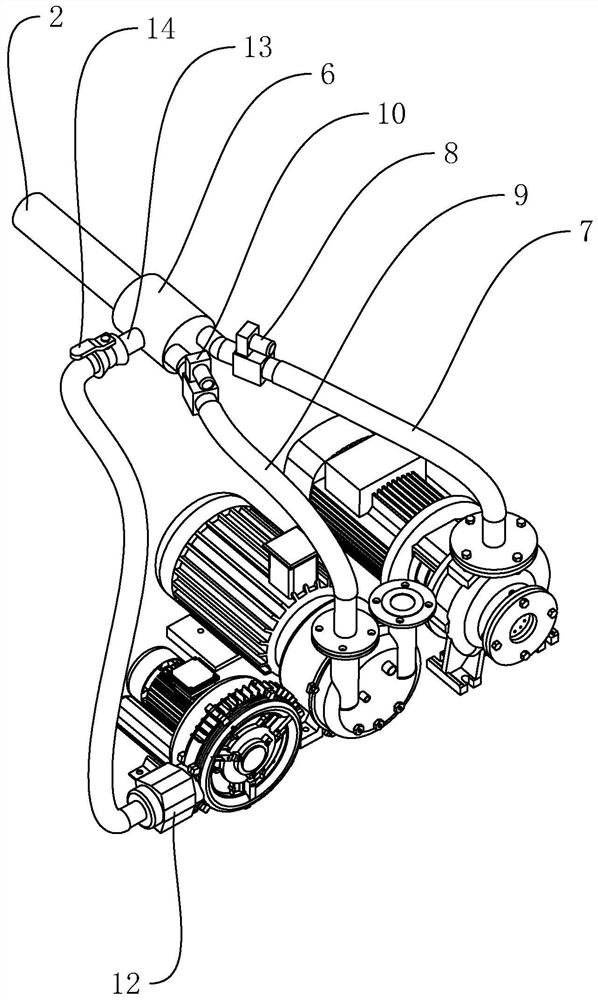

[0033] refer to figure 1 and figure 2 , a hydraulic coil testing device, comprising an installation shell 1, an infusion tube 2 and a high-pressure water pump 3, the installation shell 1 is supported on the ground, an opening is opened on one side of the installation shell 1, and the infusion tube 2 is installed on one end of the installation shell 1 On the inner wall, the opening side of the installation shell 1 is rotatably connected with a cover plate 26 for blocking the opening of the installation shell 1. The outer wall of the cover plate 26 is penetrated with an observation port 28, and a transparent glass plate 29 is fixed inside the observation port 28. The tester The situation of the infusion tube 2 in the installation shell 1 can be observed in real time through the transparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com