Optical driving assembly

A technology for driving components and optical components, applied in optical components, optics, instruments, etc., can solve the problems of limited anti-shake effect, high unit price, high power consumption, etc., to achieve the effect of optical anti-shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

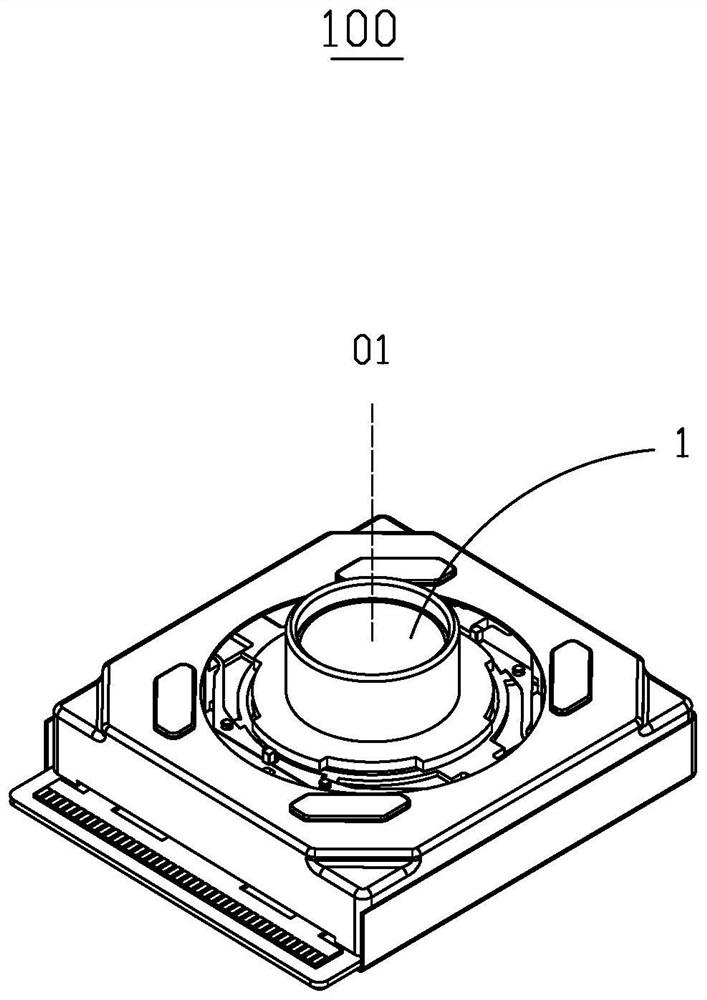

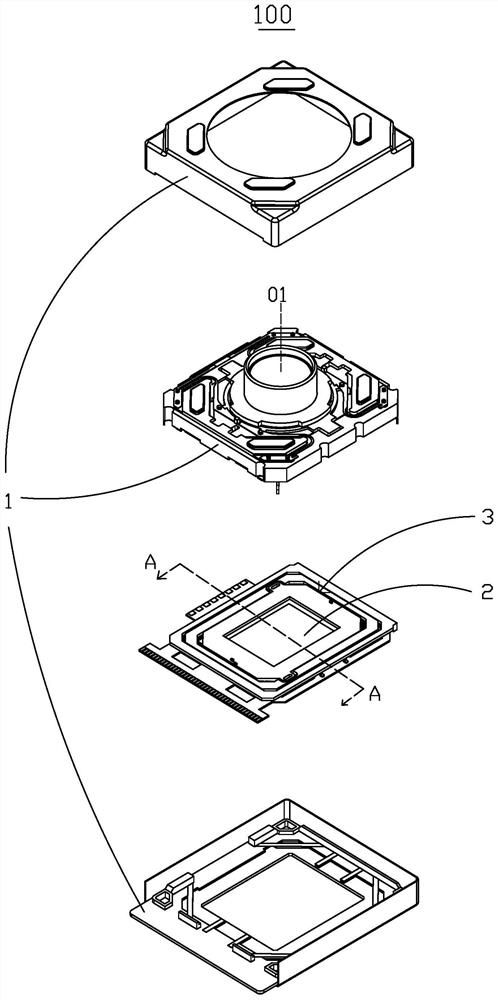

[0030] see Figure 1-Figure 10 , the embodiment of the present invention provides an optical driving assembly 100, including an optical element 1, an optical sensor 2 and a driving module 3. The optical element 1 has an optical axis 01, the optical sensor 2 and the optical element 1 are arranged along the optical axis 01, and the driving module 3 drives the optical sensor 2 to translate along a direction perpendicular to the optical axis 01.

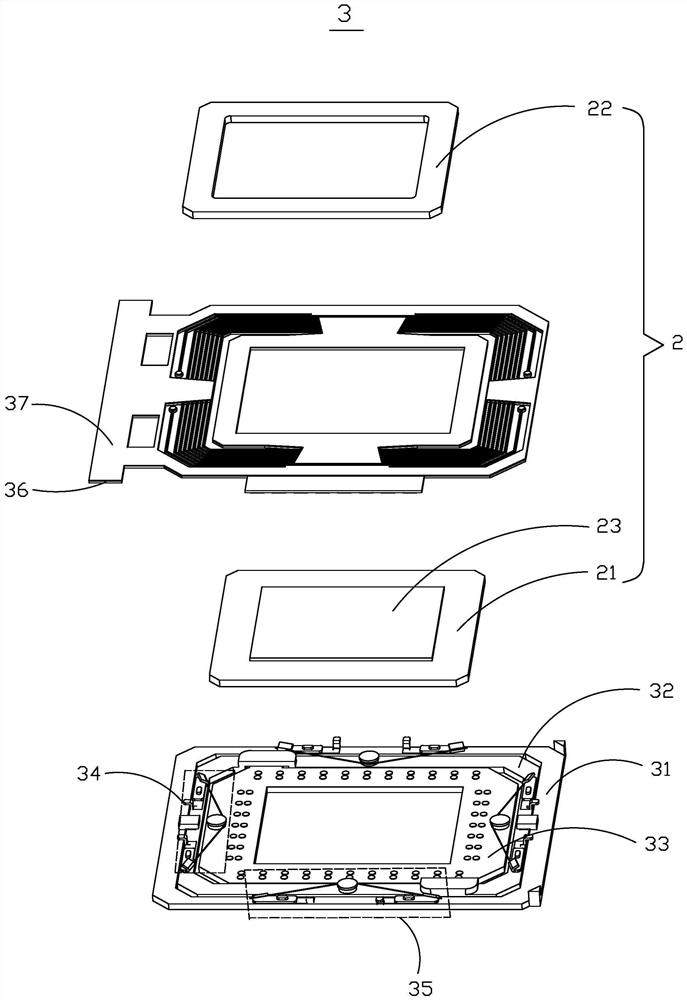

[0031]The driving module 3 includes a fixed part 31 , a movable part 32 , a bearing part 33 , a first driving assembly 34 and a second driving assembly 35 . Wherein, the fixed part 31, the movable part 32 and the bearing part 33 are all rectangular frames, and the optical sensor 2 is rectangular. The fixed part 31 is provided with a first movable chamber 311, the movable part 32 is provided with a second movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com