Imaging module and manufacturing method thereof

The technology of an imaging module and its manufacturing method is applied in the directions of image communication, telephone structure, television, etc., which can solve the problems of large volume of imaging module and lateral movement of moving components, etc., and achieve small size, no electromagnetic interference, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

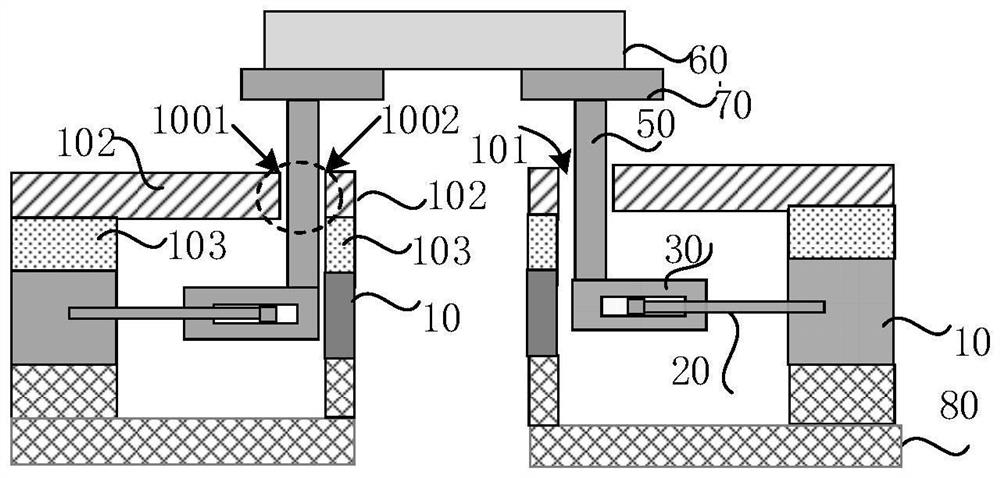

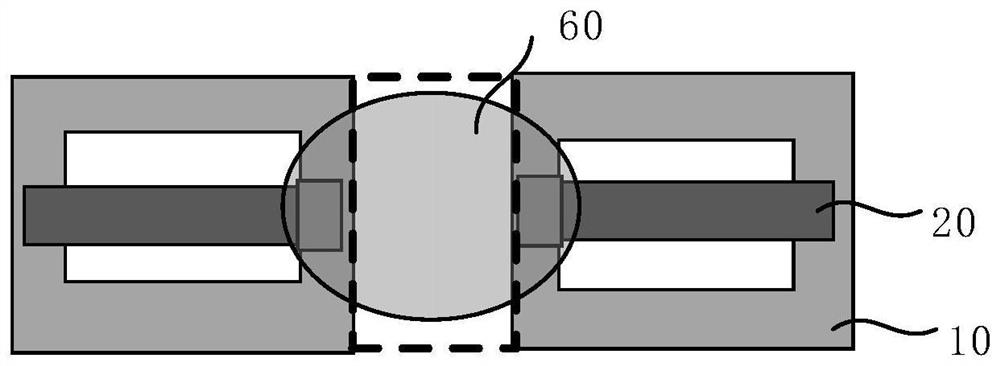

[0045] figure 1 It is a schematic structural diagram of an imaging module according to an embodiment of the present invention, Figure 2A for figure 1 For a top view, please refer to figure 1 and Figure 2A , the imaging module includes:

[0046] The moved element 60, the moved element 60 includes a lens group, an imaging sensing element, an aperture or a lens sheet;

[0047] at least one support block 10, the at least one support block encloses a space above which the moved element 60 is suspended;

[0048] At least two piezoelectric elements 20, including a movable end and a fixed end, the fixed end is fixed to the support block 10, and the movable end is at least partially located in the limiting groove 30; the at least two piezoelectric elements 20 are distributed on the periphery of the moved element 60;

[0049] A connecting arm 50, one end of which is connected to the moved element 60, and the other end is connected to the limiting groove 30;

[0050] The lateral...

Embodiment 2

[0072] refer to Figure 13 , the support blocks 10 are a pair, symmetrically distributed on both sides of the moved element 60, each support block 10 is provided with a piezoelectric element 20 on the upper surface, two piezoelectric elements 20 are symmetrically arranged, and the connecting arm 50 is arranged along the piezoelectric Two vertical first walls 104A and second walls 104B are provided on both sides of the element 20 in the length direction, and the two vertical first walls 104A and second walls B are respectively used as lateral movement limiters. The first side wall and the second side wall, the distance between the two vertical first walls 104A and the second wall 104B is slightly larger than the outer diameter of the connecting arm 50, when the piezoelectric element 20 warps, the piezoelectric element 20 The movable end of the electrical element 20 drives the connecting arm 50 through the limiting groove 30, and the connecting arm 50 drives the moved element 60...

Embodiment 3

[0075] refer to Figure 14 , the support block 10 is a pair, symmetrically distributed on both sides of the moved element 60, the support block 10 includes two sub-support blocks in the up and down direction, and the piezoelectric element 20 is fixed between the two sub-support blocks. The lateral movement limiter is a first upper cover 105 with a first opening 106 arranged on the upper surface of the support block 10. One end of the connecting arm 50 is connected to the limit groove 30 through the first opening 106, and the other end is connected to the moving position. On the lower surface of the element 60, the shape of the first opening 106 matches the connecting arm 50, and the size is slightly larger than the outer diameter of the connecting arm 50. The two inner walls of the first opening 106 that limit the lateral movement of the connecting arm 50 serve as lateral movement limiters. The first side wall and the second side wall of the piece. In this embodiment, each su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com