Processing module for robot

A technology for processing modules and robots, which is applied in the field of robotics and can solve problems such as crowding available bandwidth, increasing system complexity, and routing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

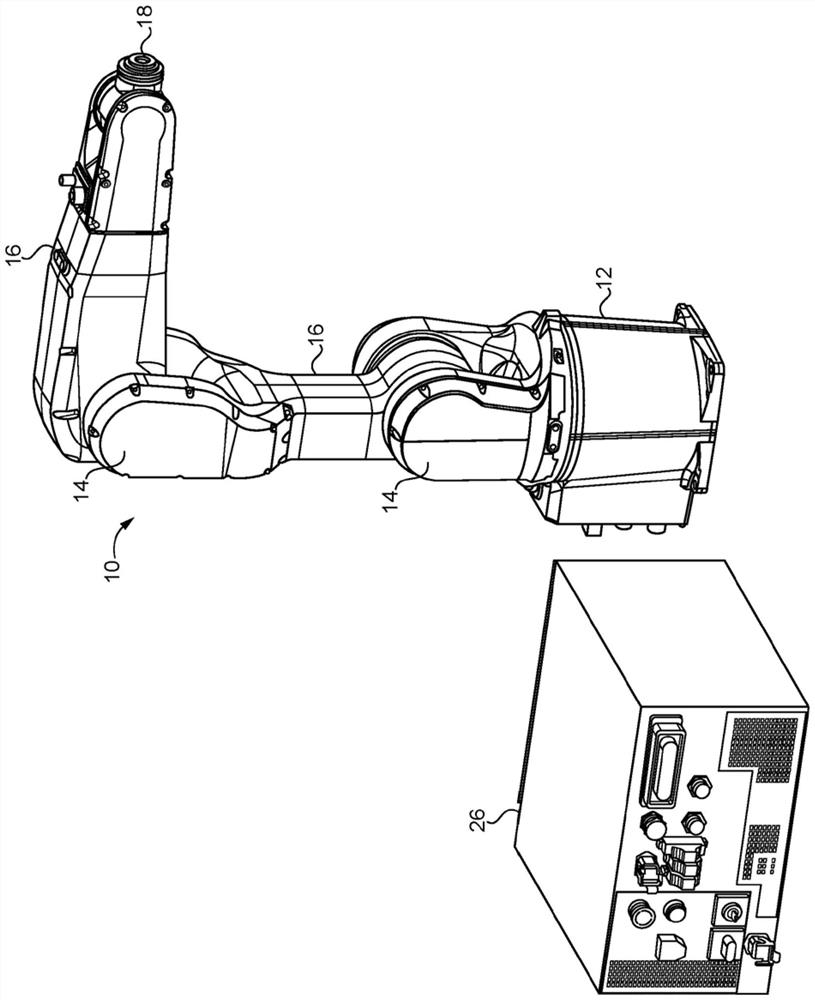

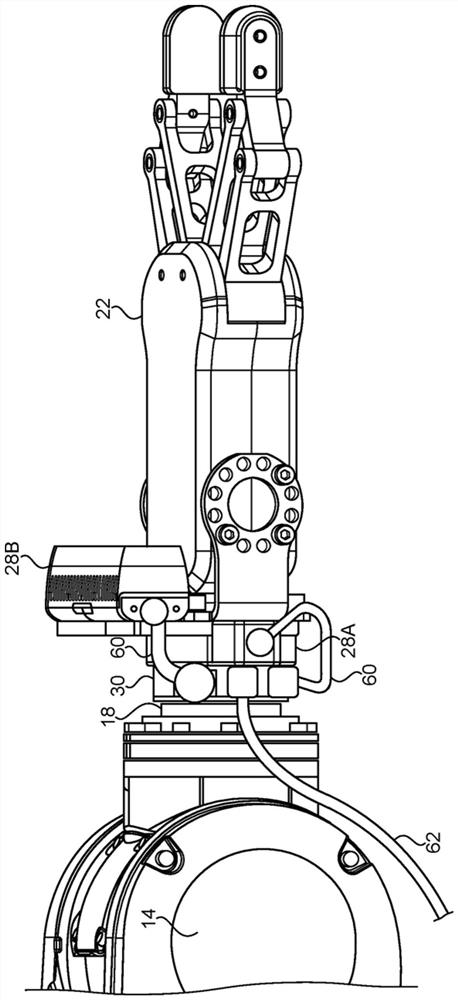

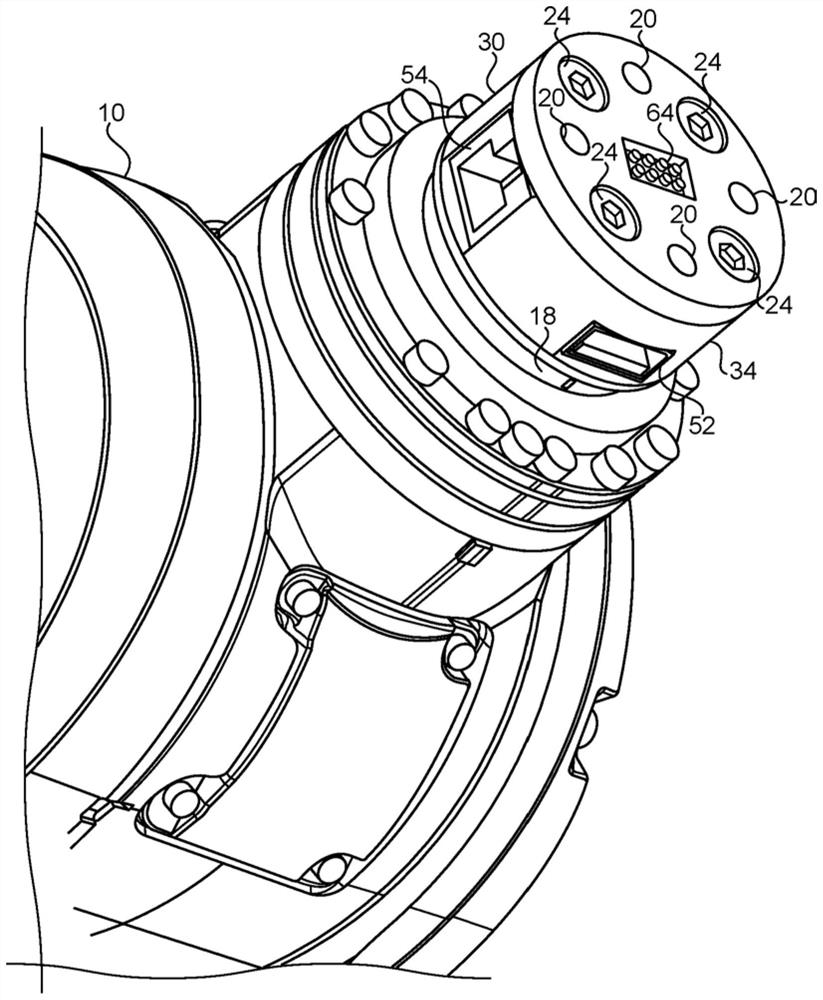

[0020] Referring now to the drawings, and in particular figure 1 , an example of a robot 10 is shown. As shown, the robot 10 has a base 12 which may be fixed in place or movable. The robot 10 is provided with one or more joints 14 that allow a member 16 of the robot 10 (eg, the arm 16 ) to be moved in different directions. although figure 1 A pivot joint 14 is illustrated in , but it is also possible that the joint 14 could be a linearly extendable joint, a rotational joint or other type of joint that allows movement between the two members 16 of the robot 10 . At the end opposite the base 12 , the robot 10 may be provided with a robot tool mounting surface 18 , or tool flange 18 . Preferably, the tool flange 18 (e.g., Figure 4 ) is an industry standard tool flange 18 that allows end effectors 22 of different manufacturers to be attached to the tool flange 18. For example, preferred industry standard tool flanges meet ISO 9409-1:2004(E). In particular, the tool flange 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com