Method and system for controlling turbomachine with control saturations management

A turbine engine and control system technology, applied in the direction of turbine/propulsion fuel delivery system, engine components, engine control, etc., can solve the problems of complex implementation, unsatisfactory use of turbine engines and unsatisfactory correctors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

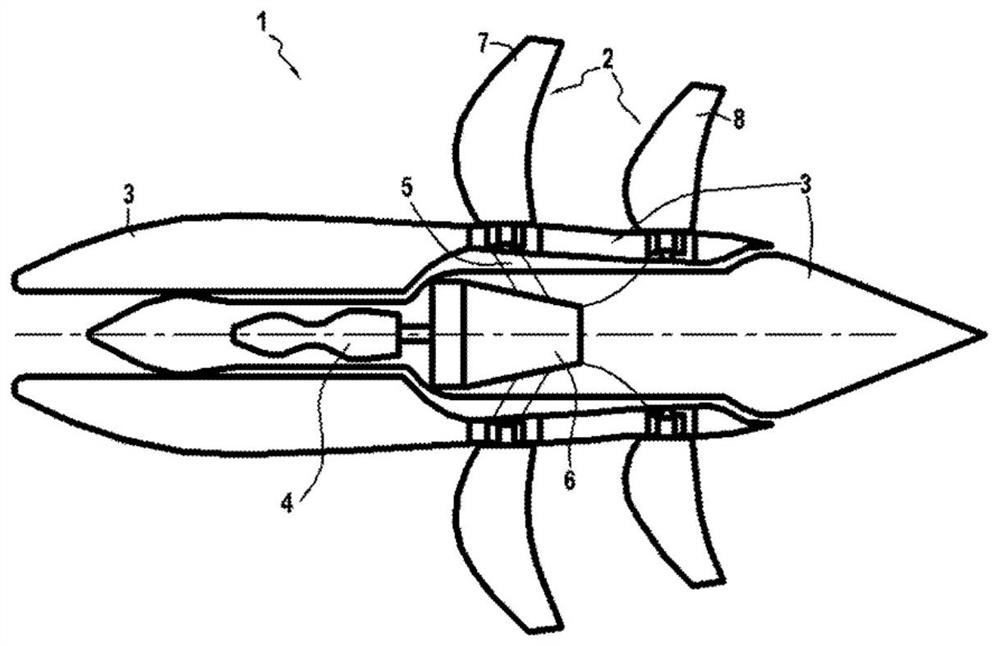

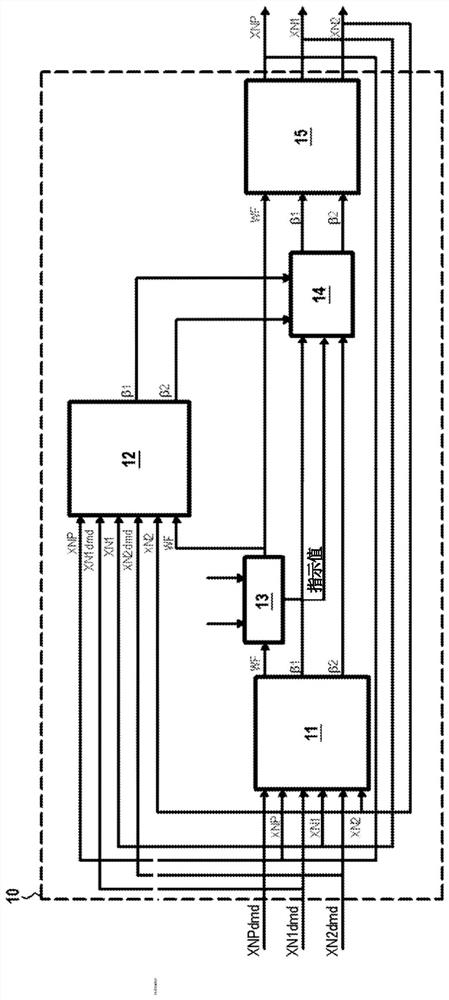

[0049] image 3 A system 10 for controlling a turbine engine according to an embodiment of the invention is schematically represented. The turbine engine controlled by the control system 10 according to the invention may be a turbine engine 1 with an unducted fan, e.g. figure 2 Turbine engine described in.

[0050] The control system 10 includes a first corrector 11 , a second corrector 12 , a first selection unit 13 , a second selection unit 14 and an integrator 15 .

[0051] The first corrector 11 comprises three outputs delivering a first value for each of the three controlled quantities. The first control amount corresponds to the fuel flow WF of the open rotor 1, and the second control amount corresponds to the pitch β of the upstream propeller of the open rotor 1 1 , the third control amount corresponds to the pitch β of the downstream propeller of the open rotor 1 2 .

[0052] The first corrector 11 receives as input the values of three variables of the open rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com