Fuzhuan brick tea pressing production line and pressing process

A production line and Fuzhuan brick technology, which is applied in the direction of manufacturing tools, presses, chemical instruments and methods, etc., can solve the problems of affecting tea processing efficiency and low production efficiency of Fuzhuan brick tea pressing, so as to improve cooling efficiency and reduce air blowing Blind area, the effect of improving the efficiency of press processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

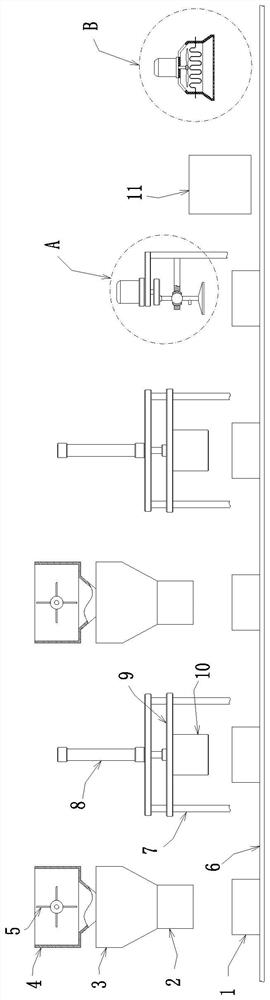

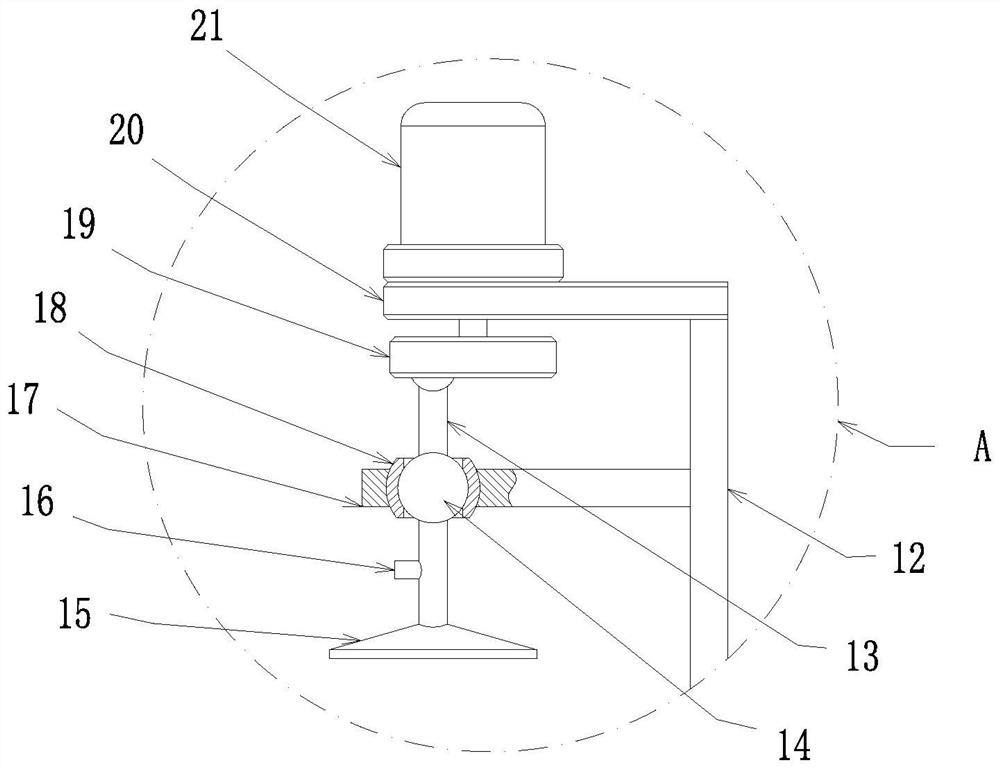

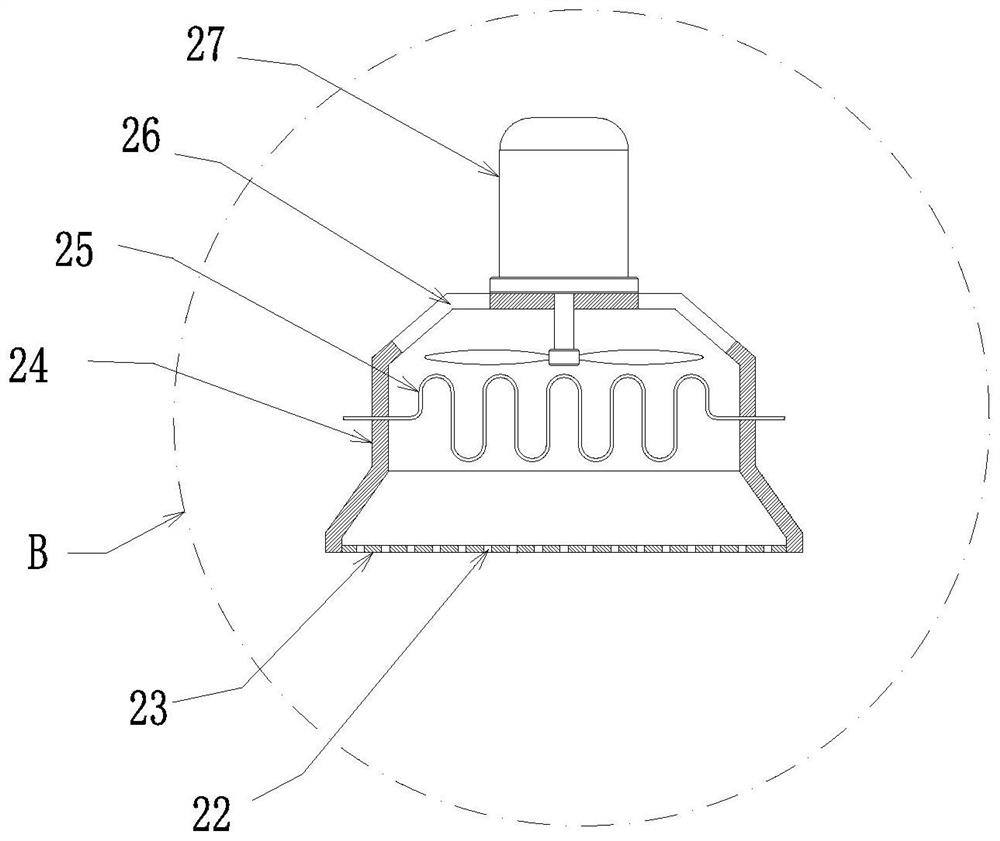

[0027] Such as Figure 1-3 As shown, a Fu brick pressing production line includes a conveying mechanism 6 for conveying a plurality of stuffing boxes 1, a packing mechanism, a pressing mechanism, an air blowing mechanism, a manipulator 11, an air-cooled mechanism, the filling mechanism and the pressing mechanism are provided with two and alternately arranged, the filling mechanism is used to put tea raw materials into a plurality of stuffing boxes 1 in turn, the filling mechanism includes a tea steaming device 4 arranged above the conveying mechanism 6, and the tea steaming device 4 is equipped with There is a stirring rod 5 driven by an external motor. When the stirring rod 5 rotates, it can stir the tea raw materials in the tea steaming device 4. The outlet of the tea steaming device 4 is connected with a weighing device 3, and the weighing device 3 is connected through the There is a feeding bin 2, and a weighing device 3 is used to weigh the tea raw materials in the tea st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com