A packaging machine for intelligent manufacturing of automobile pillows

A technology of intelligent manufacturing and packaging machines, applied in packaging, transportation packaging, packaging protection, etc., can solve problems such as wasting time, car pillow detection, and reducing equipment work efficiency, so as to prevent waste and increase work speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

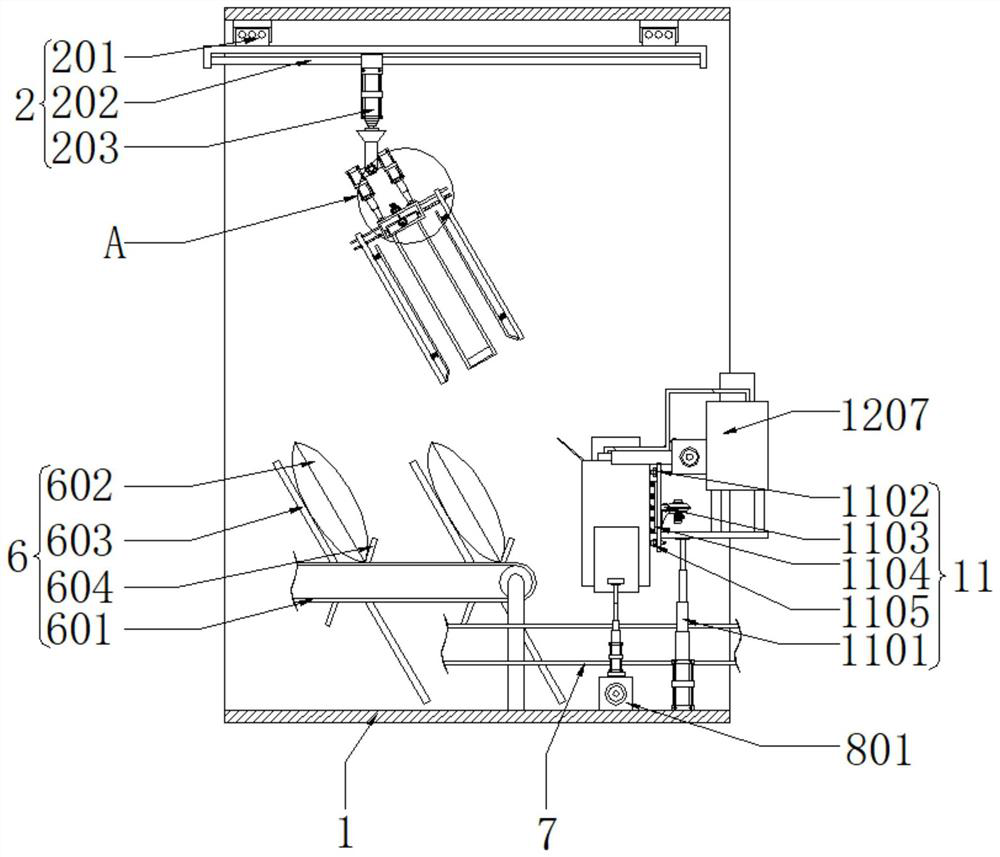

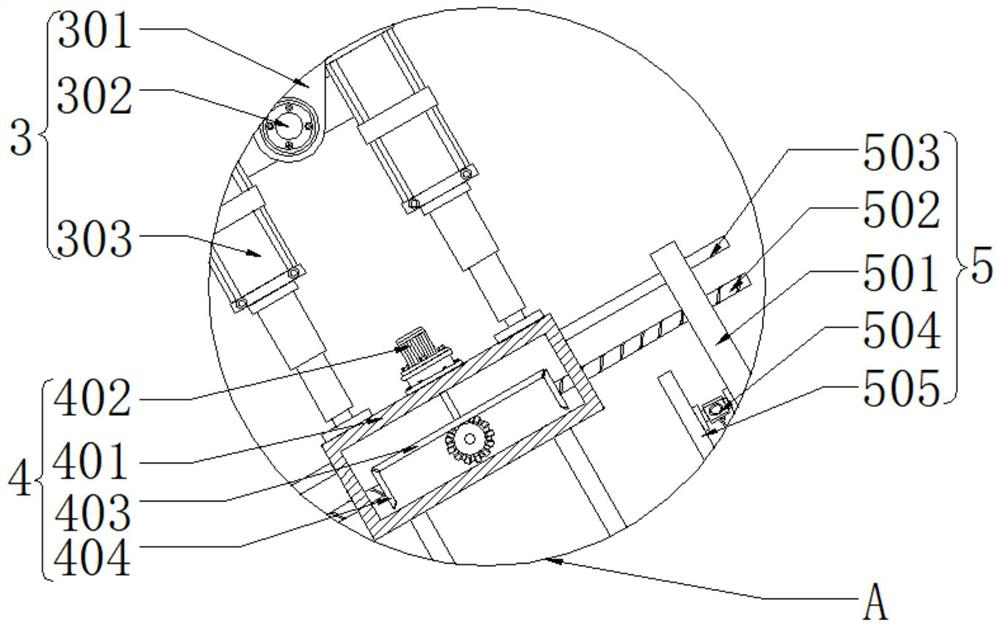

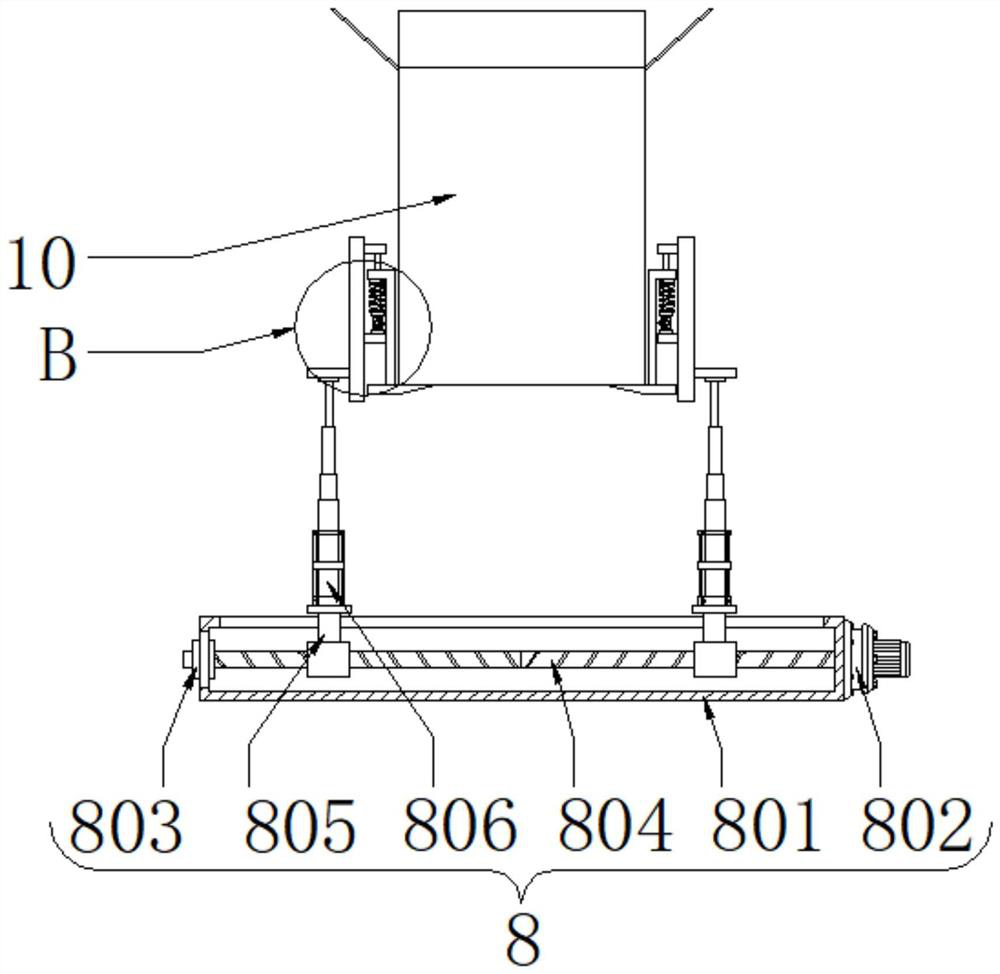

[0028] Such as Figure 1 to Figure 5 As shown, the present invention provides a technical solution: a packaging machine for the intelligent manufacture of automobile backrests, including a device housing 1 and a gluing assembly 12, the inner upper wall of the equipment housing 1 is provided with an axial movement assembly 2, and the shaft The lower end of the moving assembly 2 is provided with a rotating telescopic assembly 3, the lower end of the rotating telescopic assembly 3 is connected with an adjustment assembly 4, and the lower end of the adjustment assembly 4 is connected with a clamping assembly 5, and the inner lower wall of the equipment housing 1 is from back to front The material conveying assembly 6 and the second belt conveyor 7 are installed in sequence, and the clamping lifting assembly 8 is installed on the front and rear sides of the second belt conveyor 7, and the upper end of the clamping lifting assembly 8 is provided with a detection assembly 9, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com