Small cargo transfer equipment for warehousing service

A small, cargo technology, applied in the field of small cargo transfer equipment for warehousing services, can solve the problems of easy shaking of goods, no plywood to clamp the goods, falling on the ground, etc., to save space resources, improve work efficiency, and reduce the frequency of shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

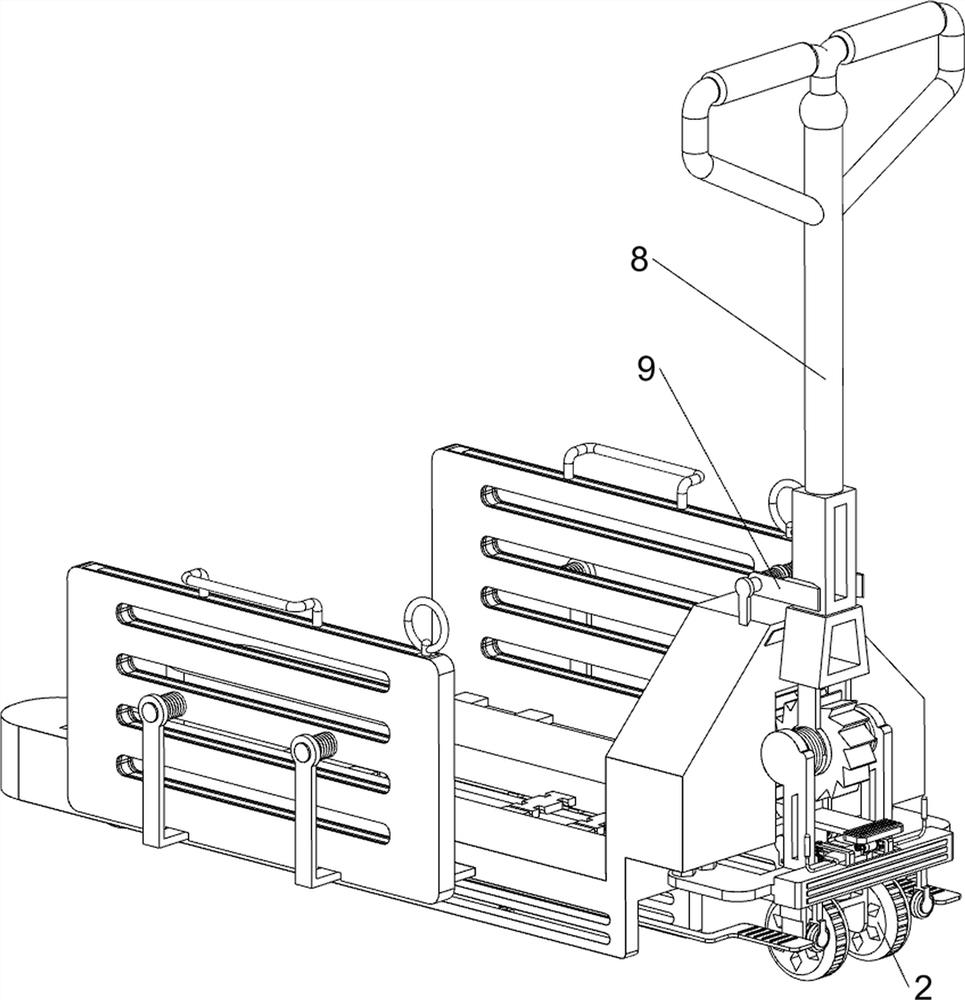

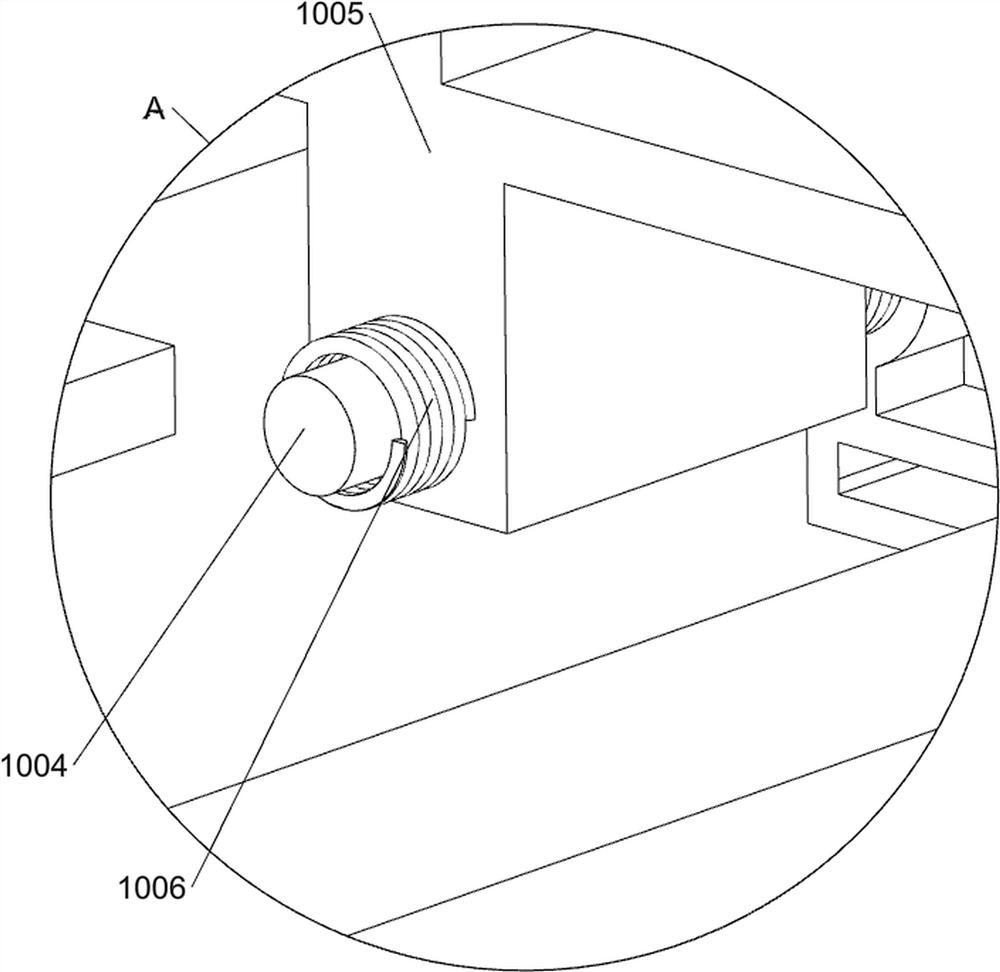

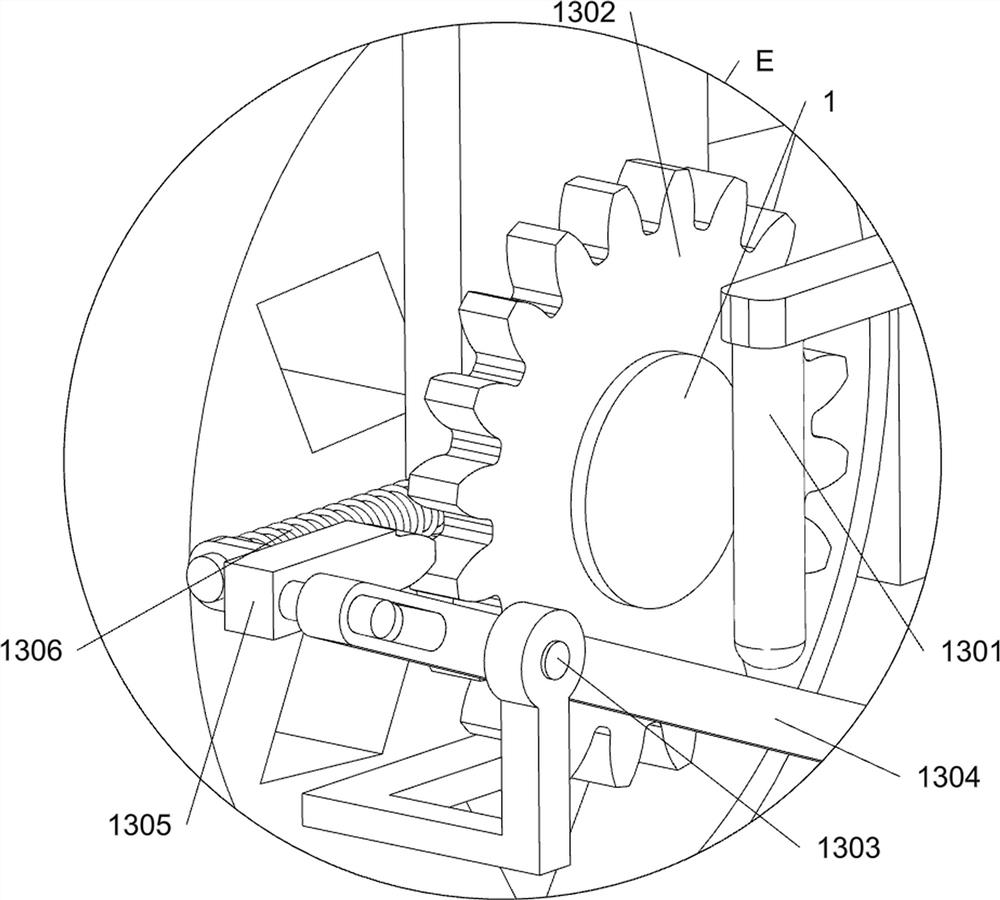

[0036] A small cargo transfer equipment for warehousing services, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 12 and Figure 13As shown, it includes a first rotating shaft 1, a wheel 2, a lifting frame 3, a connecting frame 4, a prismatic column 5, a second rotating shaft 6, a third rotating shaft 7, a tow bar 8, a stabilizing component 9 and a lifting component 10, and the connecting frame 4. Two prismatic columns 5 are installed symmetrically front and rear on the left side of the top. A lifting frame 3 is slidingly connected between the prismatic columns 5. The inside of the lifting frame 3 is connected with a first rotating shaft 1 in a symmetrical front and back rotation on the left side, and the bottom of the connecting frame 4 The right front and rear symmetrical rotation type is equipped with a second rotating shaft 6, the first rotating shaft 1 is provided with wheels 2, the second rotating shaft 6 bottom symmetrical rotation type is...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 14 , Figure 15 and Figure 16 As shown, a clamping assembly 11 is also included, and the clamping assembly 11 includes a clamping plate 1101, a groove plate 1102, a first sliding plate 1103, a second sliding plate 1104, a pull rod 1105, a second spring 1106, a buckle 1107 and a third spring 1108, the left and right sides inside the lifting frame 3 are all front and rear symmetrically slidingly connected with clamping plates 1101, the left and right sides in the middle of the lifting frame 3 are also connected to the forward and backward symmetrical clamping plates 1101, and the outsides of the middle two clamping plates 1101 are all sliding Both are connected with a groove plate 1102, and the groove plate 1102 is connected with the clamping plate 1101 on the outside. The first slide plate 1103 is slidably installed on the inside of the groove plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com