Soil nail anti-pulling fastening structure

A technology for fastening structures and soil nails, which is applied in basic structure engineering, sheet pile walls, excavation, etc., can solve problems such as inconvenience in the processing process, and achieve the effects of convenient processing, strengthening the fastening effect, and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

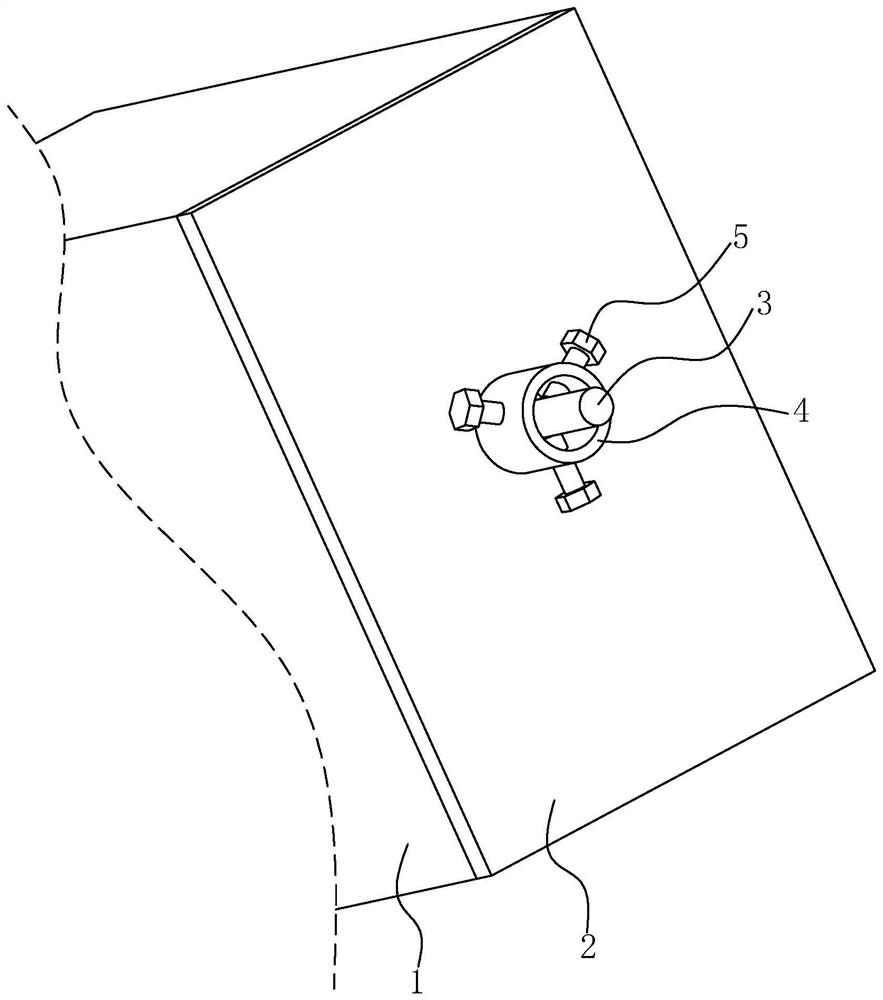

[0036] refer to figure 1 , a soil nail pullout fastening structure, used for fastening the soil nail 3 pierced on the soil 1 and the concrete surface layer 2, including the fastening sleeve 4 set on the soil nail 3 and used for tightening The fastening bolt 5 of the soil-fixing nail 3.

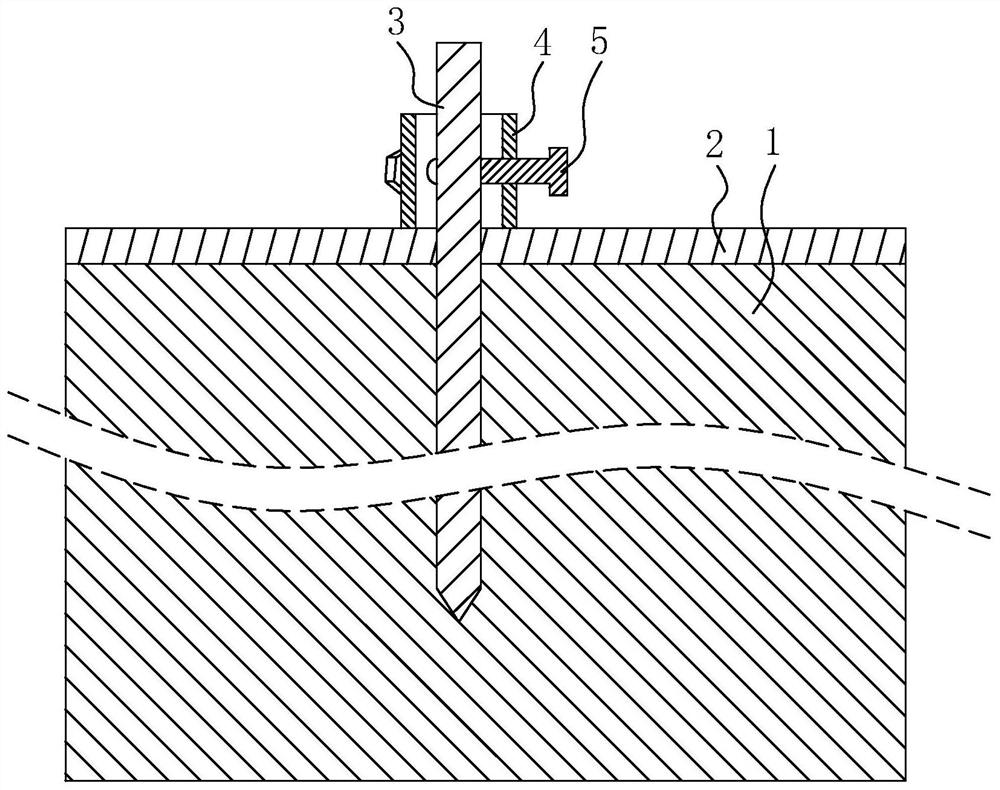

[0037] refer to figure 2 , the end face of the soil nail 3 is higher than the side of the concrete surface layer 2 away from the soil body 1, and the fastening sleeve 4 is cylindrical and pressed against the side of the concrete surface layer 2 away from the soil body 1. The tightening sleeve 4 is arranged coaxially with the soil nail 3, and several tightening bolts 5 are evenly arranged along the circumferential direction of the tightening sleeve 4. In this embodiment, three tightening bolts are arranged in the circumferential direction of the tightening sleeve 4 5. The fastening bolts 5 are set along the radial direction of the fastening sleeve 4, the fastening bolts 5 are penetrated in t...

Embodiment 2

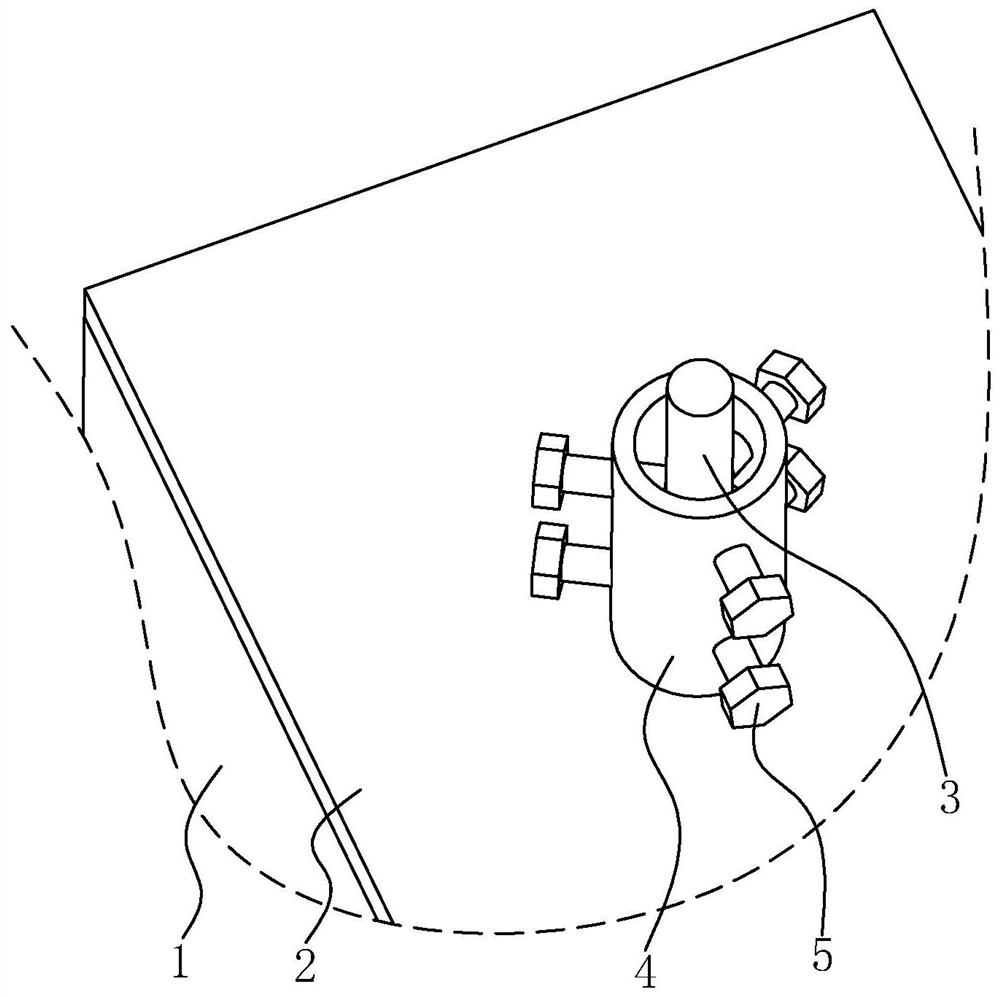

[0040] refer to image 3 The difference between this embodiment and Embodiment 1 is that several fastening bolts 5 are provided along the axial direction of the fastening sleeve 4. In this embodiment, two fastening bolts 5 are provided in the axial direction of the fastening sleeve 4. Fasten the bolt 5.

Embodiment 3

[0042] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that a backing plate 8 is fixedly provided at one end of the fastening sleeve 4 close to the concrete pad, and the soil nail 3 is pierced on the backing plate 8 . The backing plate 8 can increase the contact area between the fastening sleeve 4 and the concrete cushion, and improve the compacting effect on the concrete cushion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com