Method for constructing scale model of explosion ship in warhead cabin of anti-ship missile

A technology of scale model and construction method, which is applied in the fields of protection and explosion damage, can solve the problems of high difficulty and high cost of full-scale testing, and achieve the effects of saving test costs, accurate results, and simplifying the analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

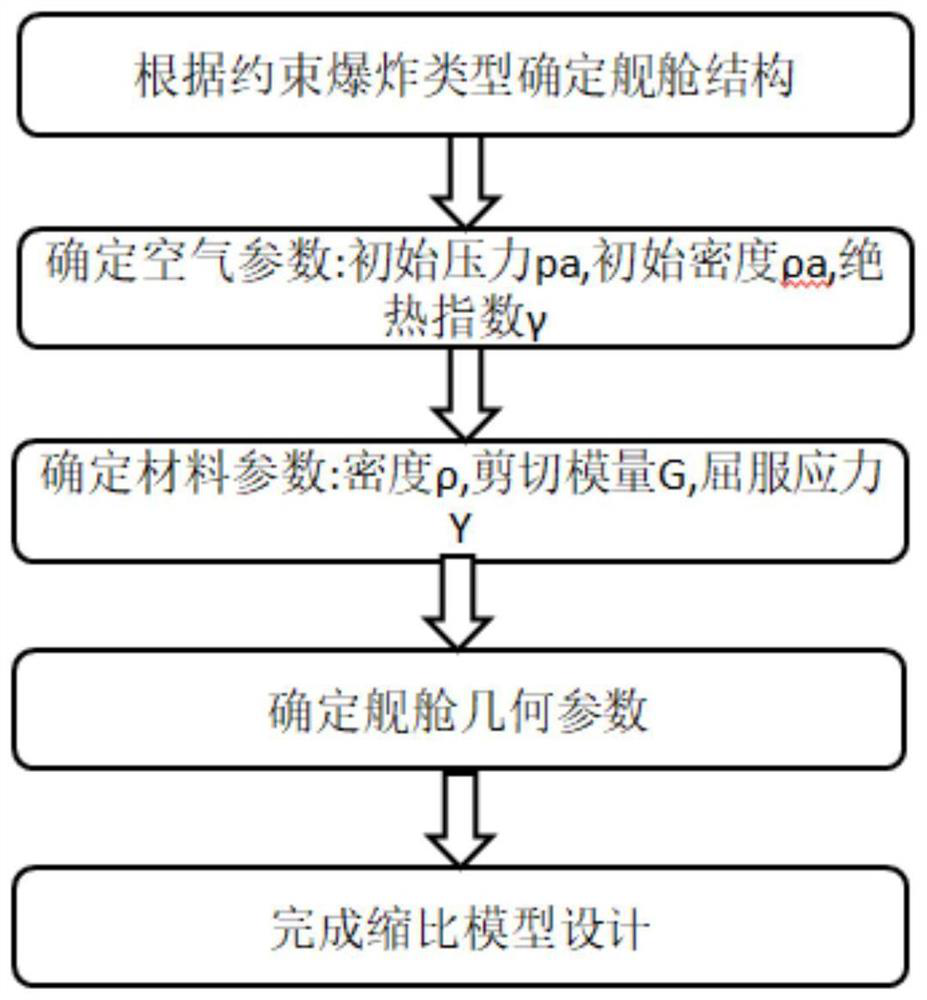

[0076] combined with figure 1 The specific steps of this design method can be understood intuitively, and the design of the scaled model of the ship exploded in the cabin of the anti-ship missile warhead can be completed according to the implementation of the steps. The present invention is explained below in conjunction with the example of destroying frigate, and example is only for explaining, and is not limited to the present invention.

[0077] In this embodiment, a scaled model design of a destroyer frigate is firstly obtained through measurement and experimentation to obtain a series of required parameters, and is calculated step by step through five steps. First, the air is simplified as an ideal medium. There is no dissipation of sound waves in air propagation, and the sound velocity and density of the air remain unchanged. They are assumed to be 346m / s and 1.185kg / m respectively. 3 . Refer to the original model to build 1 / 10, 1 / 100, 1 / 500 scale models respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com