Test system and method for hydrogen production through metal aluminum-water reaction

A technology of test system and reaction system, which is applied in the field of metal aluminum fuel energy storage and utilization, can solve problems such as the failure to meet the maximum utilization rate of aluminum powder, incomplete combustion of aluminum powder, and reduced combustion efficiency, so as to improve measurement accuracy and reduce Effects of interference and improvement of combustion efficiency

Pending Publication Date: 2021-11-16

XIAN THERMAL POWER RES INST CO LTD +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the existing problem is that for the hydrogen production process of metal aluminum-water reaction, there is a dense oxide film on the surface of aluminum powder, and it is prone to high-temperature melting and condensation during the combustion process, so that accumulation and combustion form slagging, which inhibits the internal elemental aluminum The oxidat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

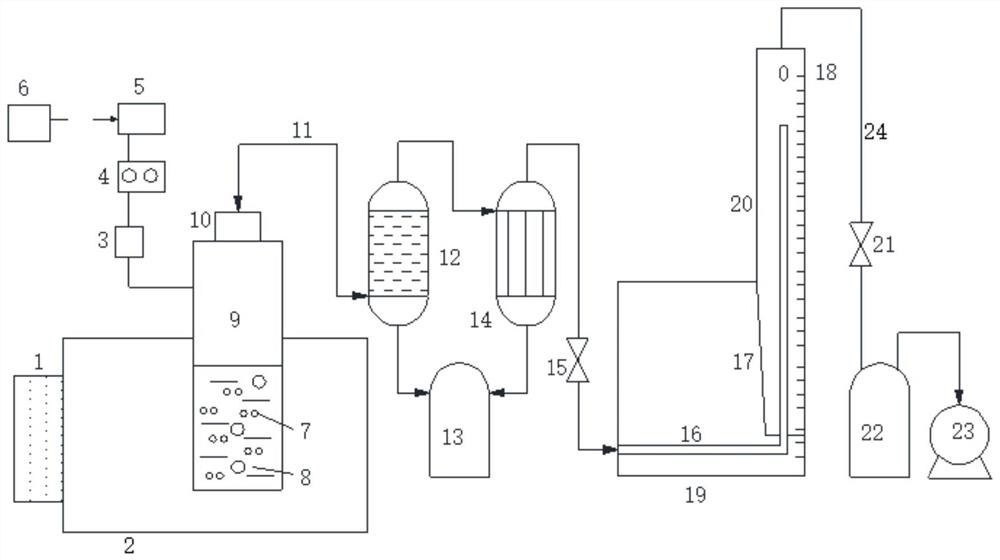

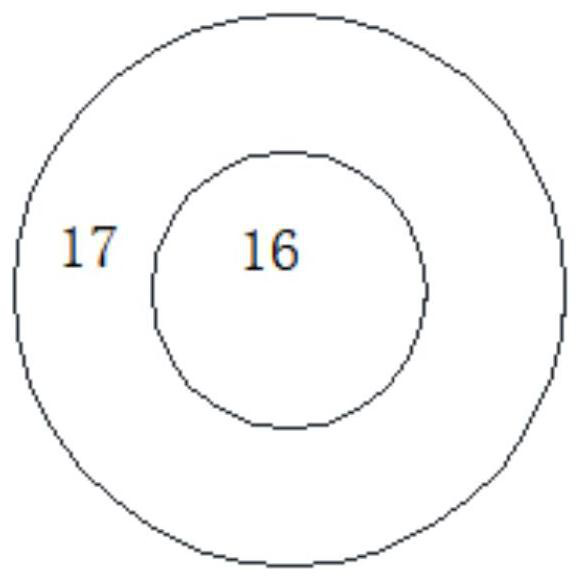

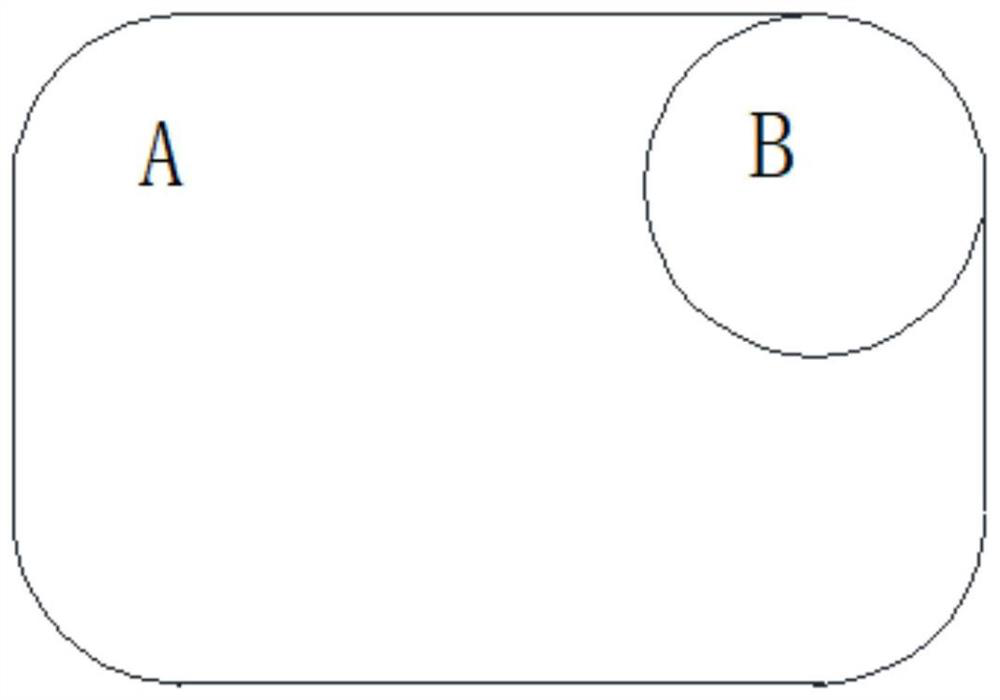

The invention discloses a test system and method for hydrogen production through metal aluminum-water reaction. The system comprises a constant-temperature reaction system, a gas collection system and a gas extraction system. The constant-temperature reaction system comprises a water bath kettle and a sealed reactor; the bottom of the sealed reactor is arranged in the water bath kettle, the top of the sealed reactor is provided with an air exhaust needle tube through a top cover with a small hole, and the side wall of the sealed reactor is connected with a measuring and recording device; the gas collection system comprises a water collection bottle, a condensing device, a water tank and a gas collection bottle; the gas collection bottle is a vertical circular tube, the top end of the gas collection bottle is sealed, the bottom of the gas collection bottle is provided with a reducing opening, the side wall of the gas collection bottle is provided with scale marks, the zero scale mark of the gas collection bottle is located above, and the interior of the gas collection bottle is communicated with a gas outlet of the condensing device through an arranged gas collection tube; the reducing side of the gas collection bottle is fixed with the inner wall of the water tank; a liquid outlet at the bottom of the condensing device is connected with the water collecting bottle, and a gas inlet at the top is communicated with an outlet of the exhaust needle tube; and the air exhaust system comprises an air exhaust pump and is communicated with the interior of the air collection bottle through an air exhaust pipe at the top end of the air collection bottle.

Description

technical field [0001] The invention relates to the technical field of metal aluminum fuel energy storage and utilization, in particular to a test system and method for hydrogen production by metal aluminum-water reaction. Background technique [0002] Facing the severe situation of depletion of fossil fuels, the comprehensive utilization of renewable energy has attracted attention. Among them, hydrogen fuel has high chemical energy, and its combustion products are non-toxic and environmentally friendly. It is a promising substitute for fossil fuels. However, the production cost of hydrogen is relatively high. Hydrogen production through metal aluminum-water reaction has been a research hotspot in recent years, and metal aluminum-water hydrogen production can be directly produced when needed, avoiding the safety problems of hydrogen storage and transportation. [0003] Many studies at home and abroad focus on the combustion characteristics of aluminum powder in different at...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N31/12

CPCG01N31/12

Inventor 向小凤白文刚张波高炜杨玉

Owner XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com