Powder spraying device and control method

A technology of spraying device and powder, applied in spraying device, spray booth, etc., can solve problems such as personal injury, poor coating effect, pollution, etc., and achieve the effect of preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

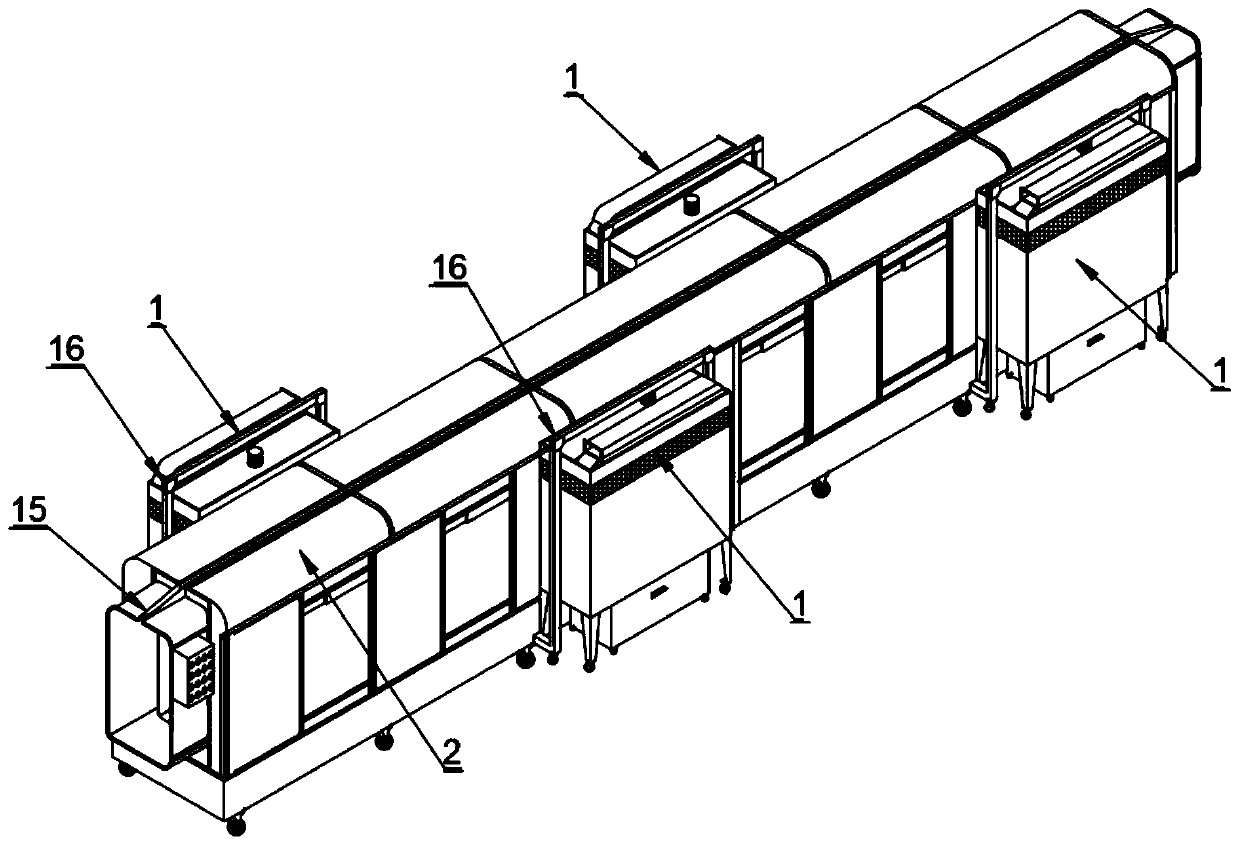

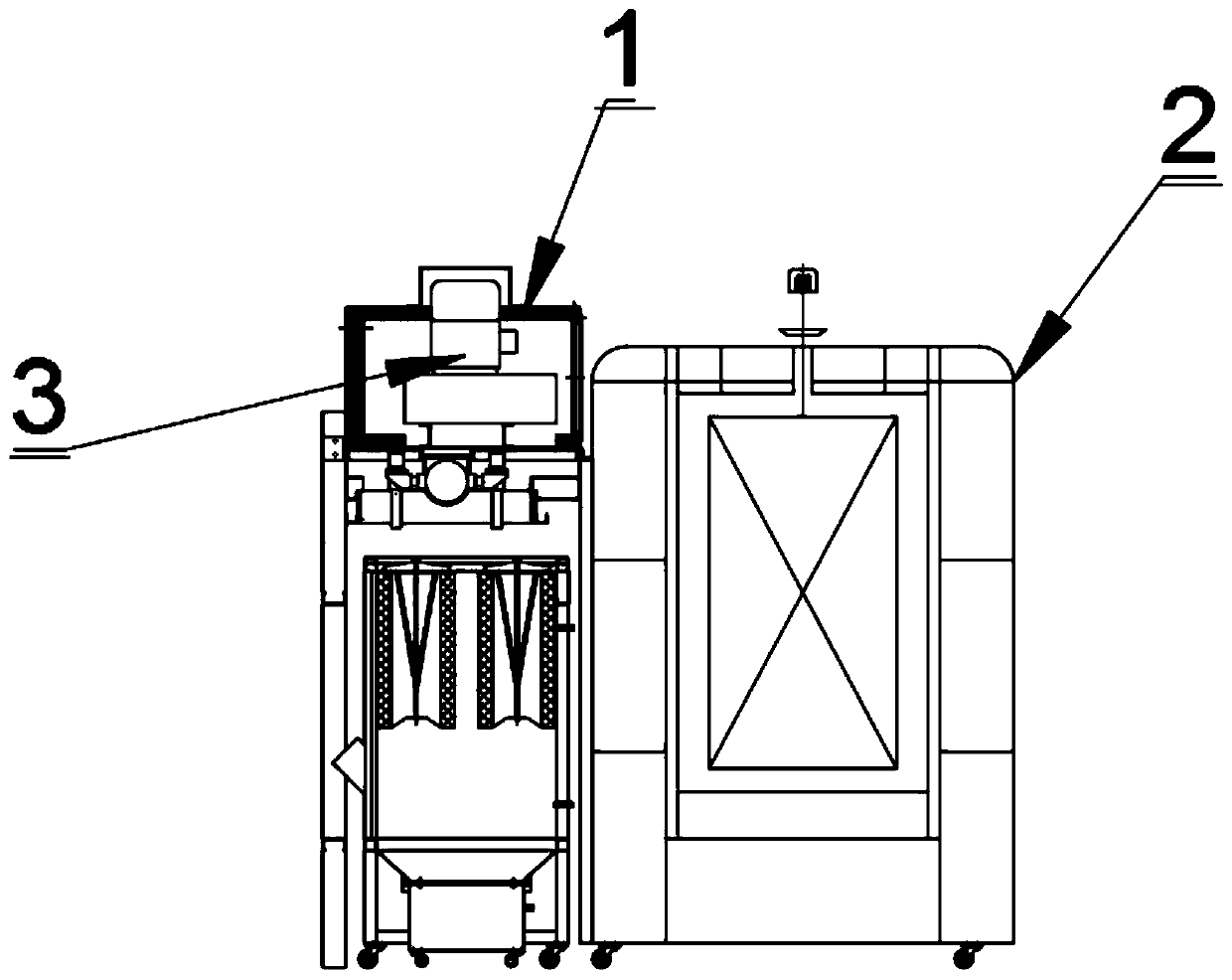

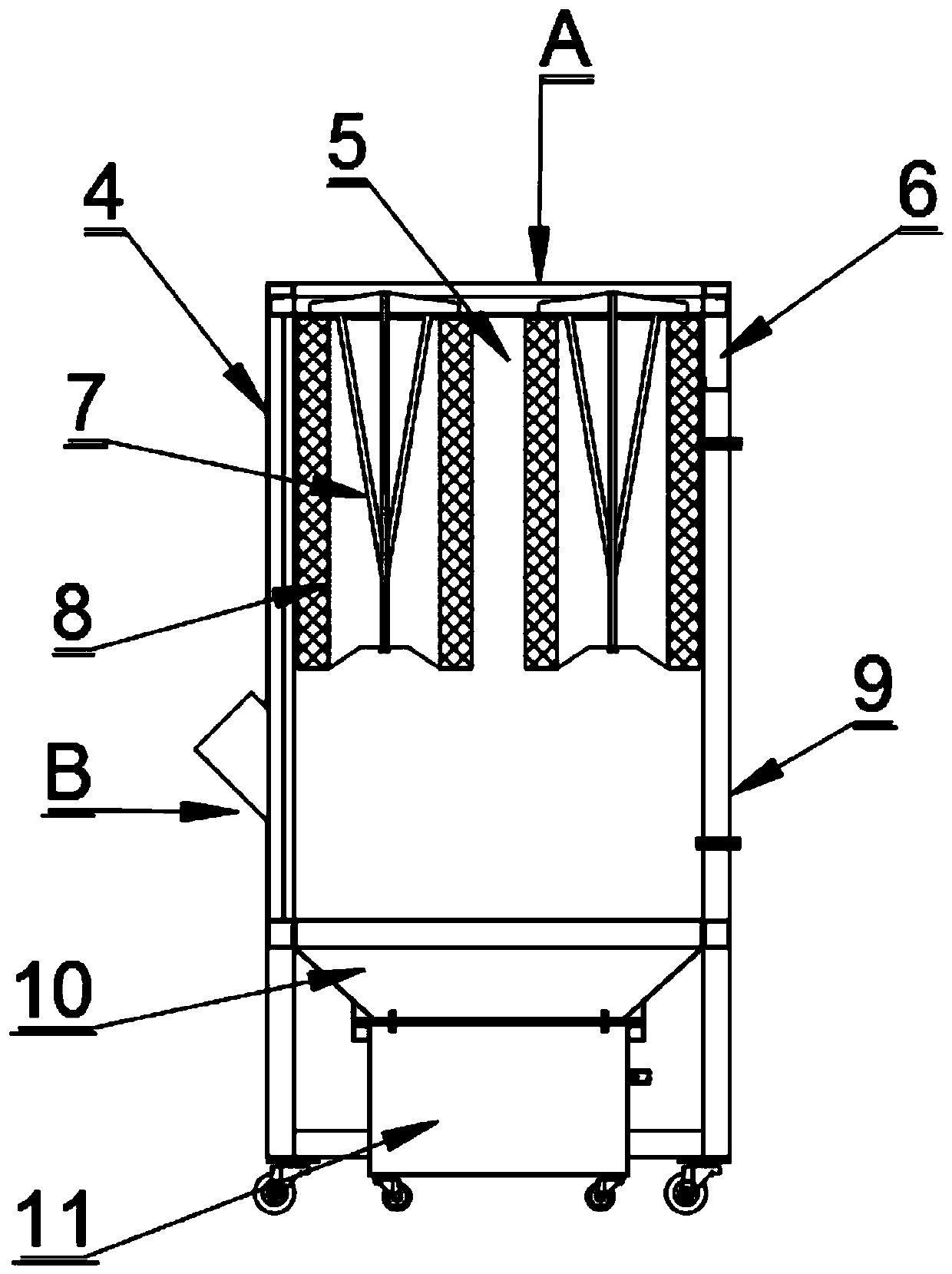

[0032]Embodiment 1: a powder spraying device, including a frame, several powder cabinets 1, a recovery tank, a mobile device and a controller, the frame includes a fuselage body 2, several limit frames 16 and each spray head, Each of the nozzles is arranged on the inner wall of the fuselage body 2 and is equally spaced, and the upper top of the fuselage body 2 is provided with a material tank 15, and the material tank 15 is along the length direction of the fuselage body 2 Extending, each of the limiting frames 16 is arranged on the side wall of the fuselage body 2, each of the limiting frames 16 is arch-shaped, and the two ends of each of the limiting frames 16 are respectively connected to the body of the fuselage. 2 is fixedly connected to the outer side wall, and each of the spacer frames 16 is respectively provided with each of the powder cabinets 1, and each of the spacer frames 16 is disassembled and engaged with the corresponding card of each of the powder cabinets 1, a...

Embodiment 2

[0034] Embodiment 2: A powder spraying device, including a frame, several powder cabinets 1, a recovery tank, a mobile device and a controller, the frame includes a fuselage body 2, several spacer frames 16 and each spray head, Each of the nozzles is arranged on the inner wall of the fuselage body 2 and is equally spaced, and the upper top of the fuselage body 2 is provided with a material tank 15, and the material tank 15 is along the length direction of the fuselage body 2 Extending, each of the limiting frames 16 is arranged on the side wall of the fuselage body 2, each of the limiting frames 16 is arch-shaped, and the two ends of each of the limiting frames 16 are respectively connected to the body of the fuselage. 2 is fixedly connected to the outer side wall, and each of the spacer frames 16 is respectively provided with each of the powder cabinets 1, and each of the spacer frames 16 is disassembled and engaged with the corresponding card of each of the powder cabinets 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com