New device for drying sample during micro nano device making process

A manufacturing process and new device technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of convenient use and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0022] Specific examples, but without any limitation to the claims of the patent of the present invention, such as cleaning and drying of silicon carbide:

example 1

[0023] Example 1, the steps are as follows:

[0024] 1) The purchased silicon carbide is cut into a square with a side length of 2cm×2cm;

[0025] 2) cleaning the silicon carbide substrate;

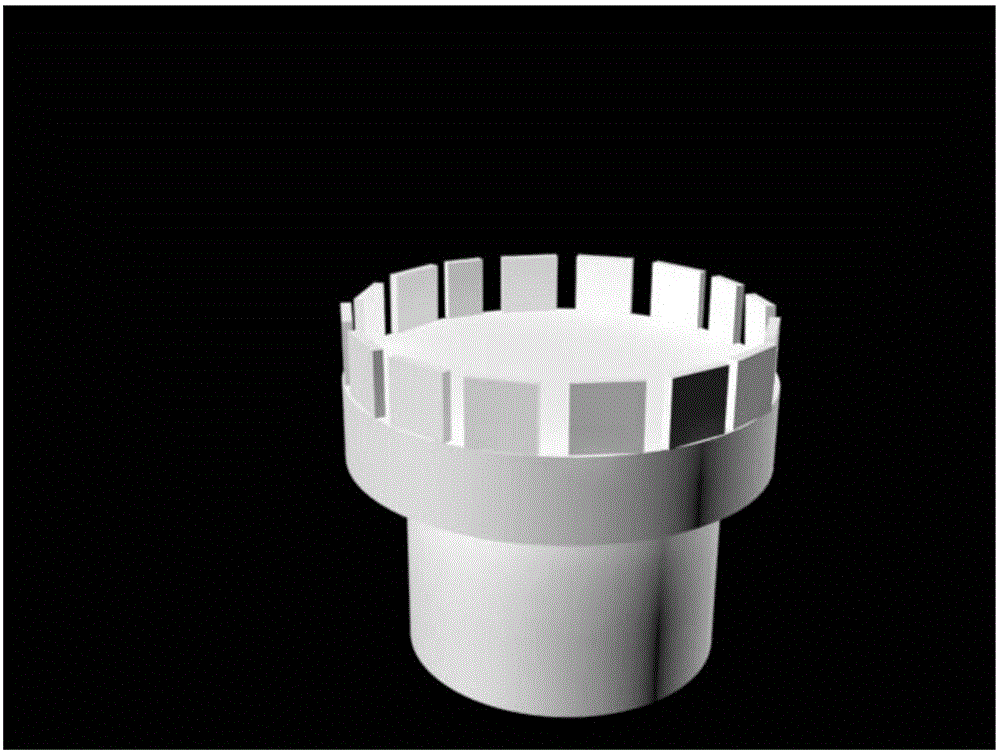

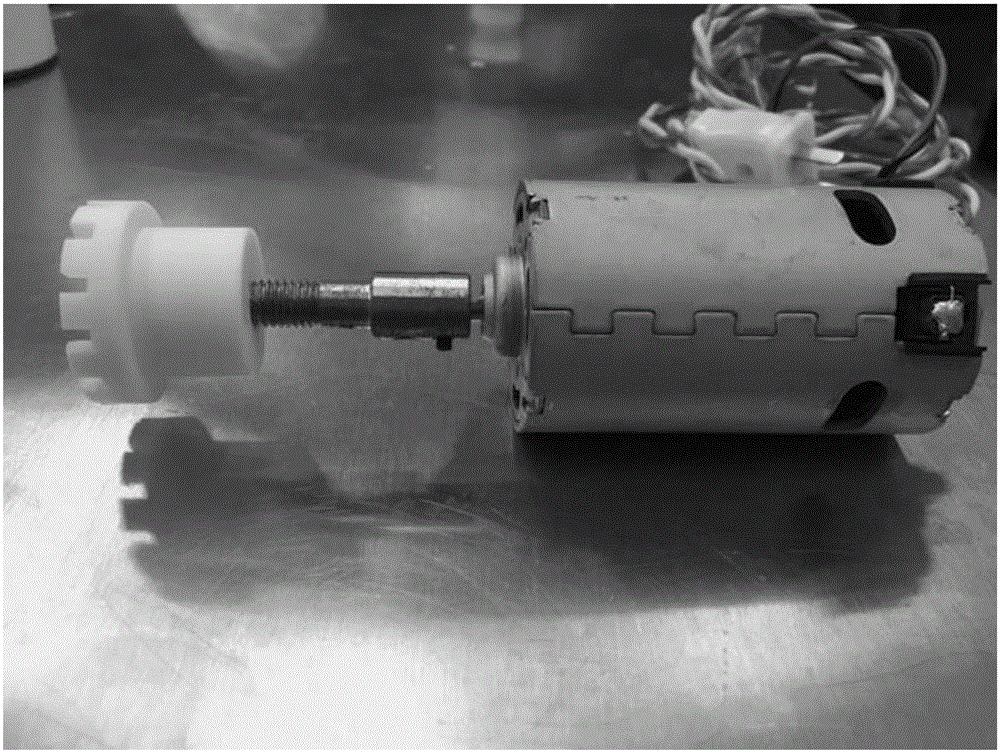

[0026] 3) Put the silicon carbide substrate ultrasonically cleaned in deionized water on a Teflon device for drying, and use the spin of the Teflon device to dry the substrate. The hollow tooth-shaped edge can not only hold the edge of the substrate to prevent the substrate from being thrown out at high speed, but also throw out the residual liquid on the substrate so that the substrate is not stained with liquid for the next drying operation .

example 2

[0027] Example 2, the steps are as follows:

[0028] 1) The purchased silicon substrate containing an oxide layer is cut into a square with a side length of 1.5cm×2cm;

[0029] 2) performing a cleaning operation on the silicon wafer;

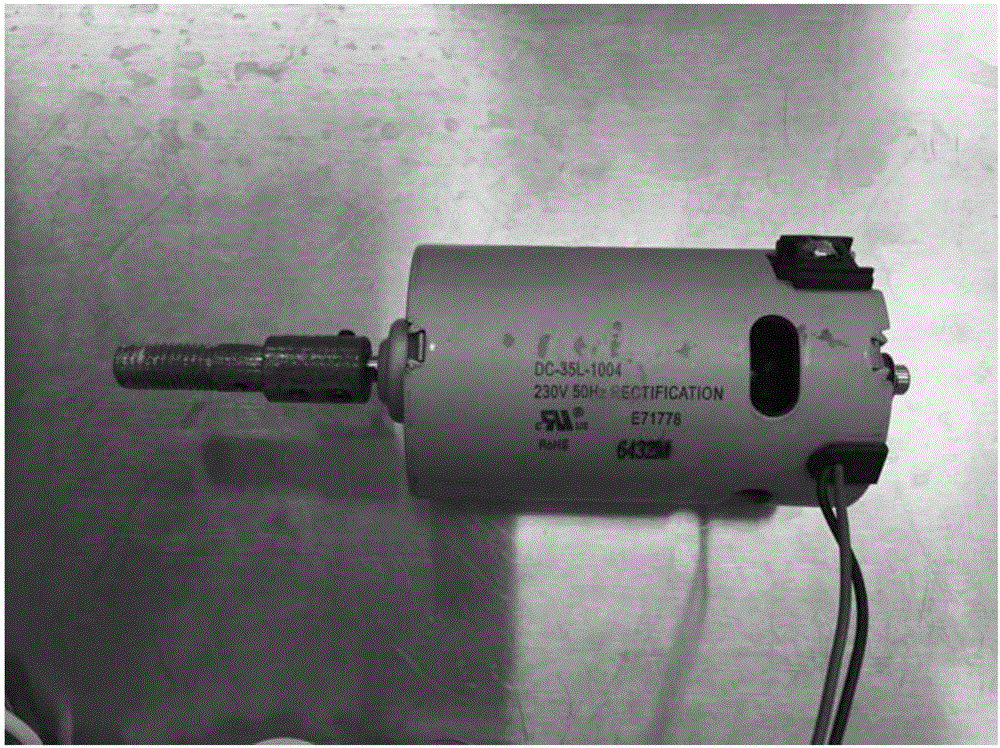

[0030] 3) Place the silicon wafer after ultrasonic cleaning in deionized water on the Teflon device for drying, and use the spin of the Teflon device to dry the substrate (it can be assembled with a small motor). The hollow tooth-shaped edge can not only hold the edge of the substrate to prevent the substrate from being thrown out at high speed, but also throw out the residual liquid on the substrate so that the substrate is not stained with liquid for the next drying operation .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com