Objective driving apparatus

A driving device and objective lens technology, applied in the configuration/installation of the head, supporting the head, protecting the transducing head, etc., can solve the problems of low operation efficiency and peeling of the protective part 110, and achieve the effect of reducing the assembly process and stabilizing the protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

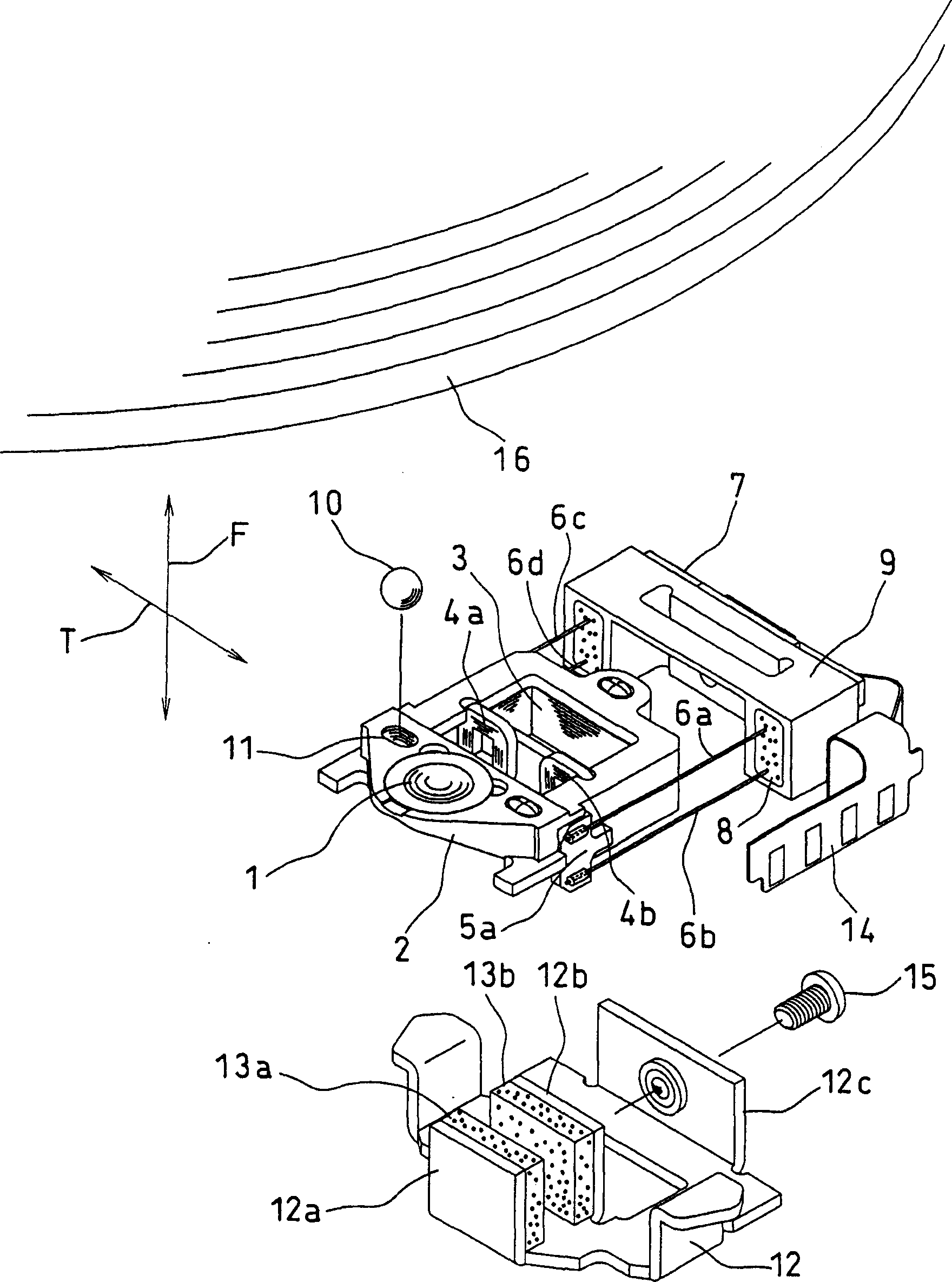

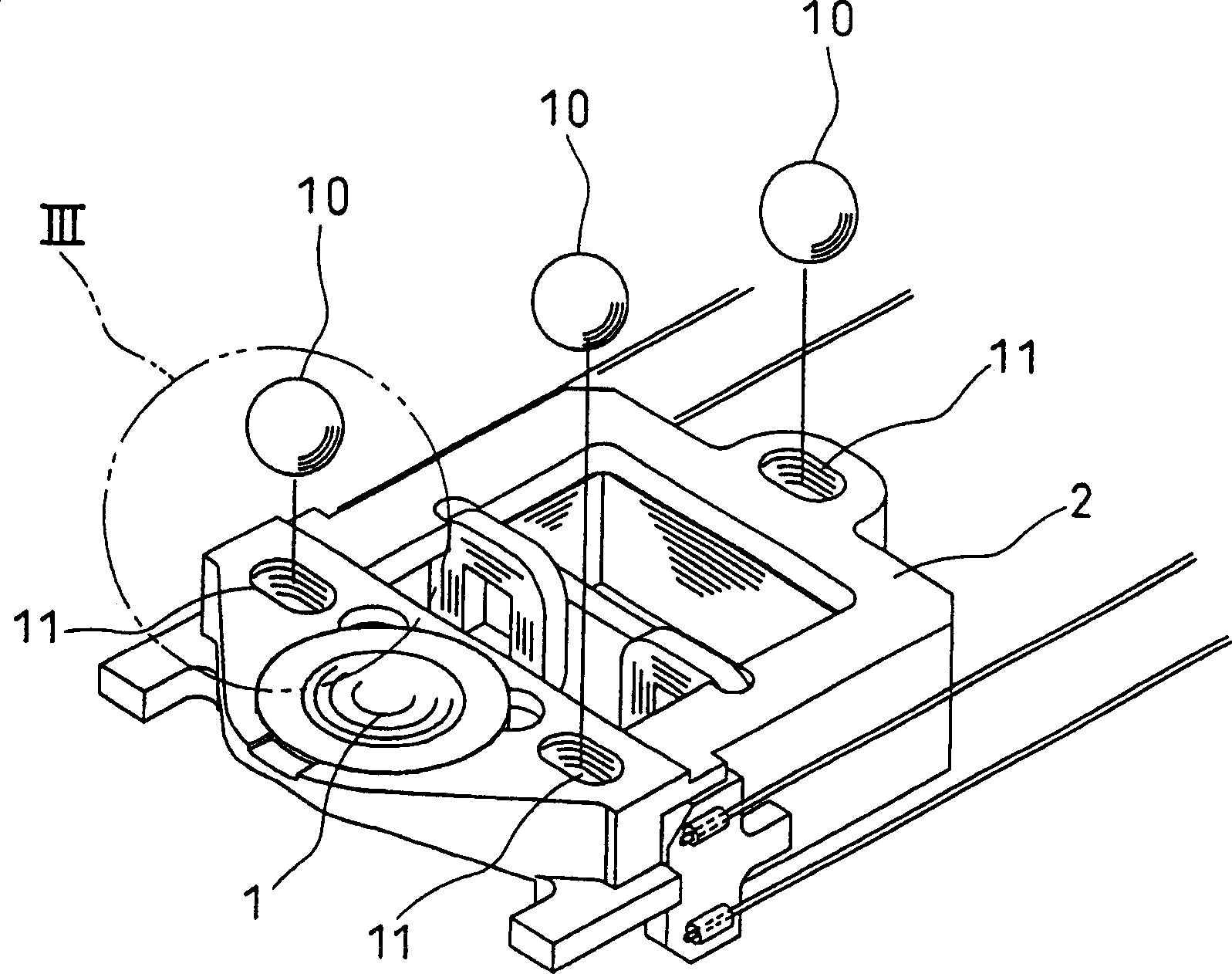

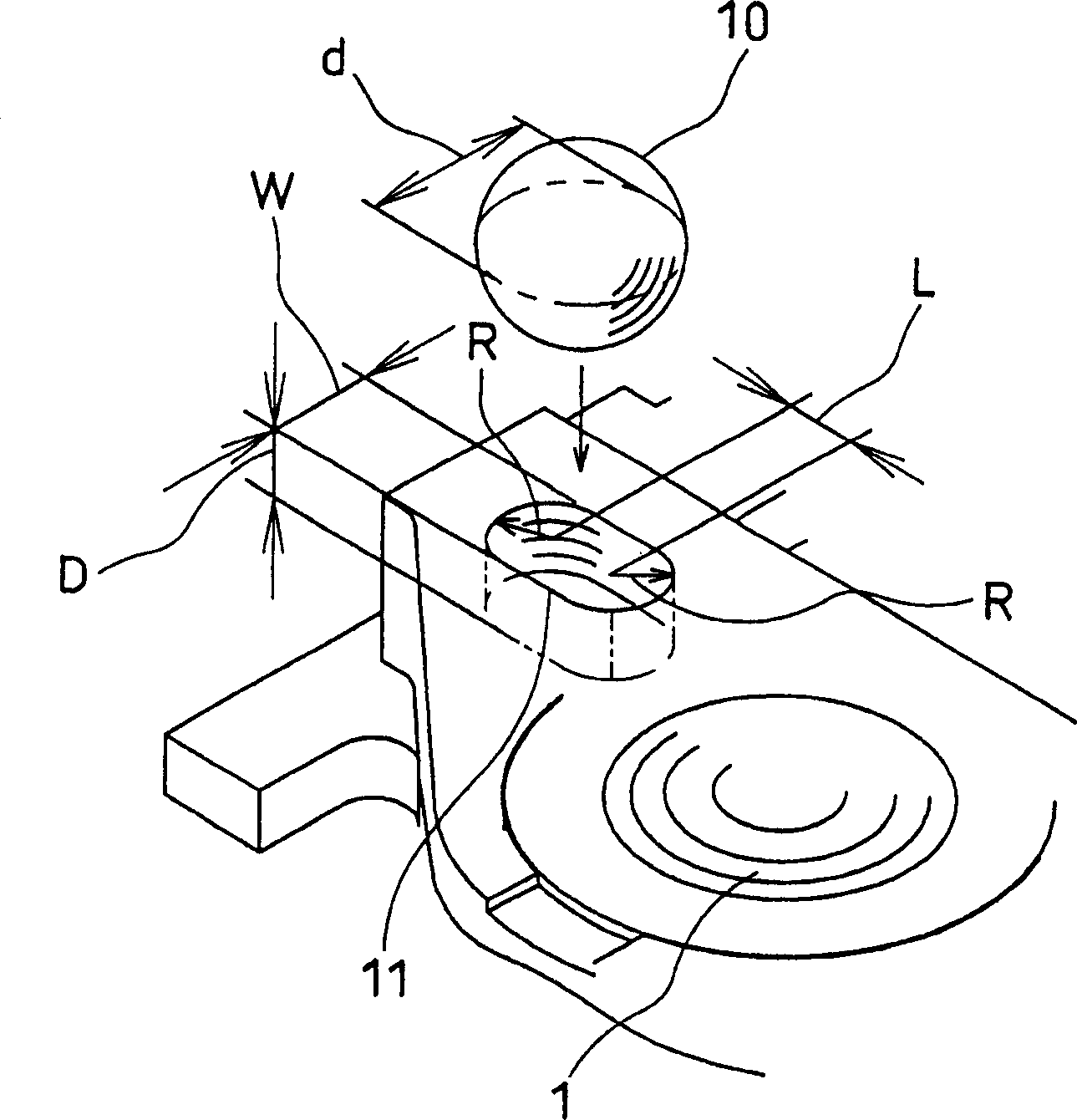

[0037] figure 1 It is an exploded perspective view showing the overall structure of the objective lens driving device in the embodiment of the present invention. figure 1 Among them, 1 is an objective lens, 2 is an objective lens holder, 3 is a focusing coil, 4a, 4b are tracking coils, 5a, 5b are coil substrates (the coil substrate 5b is not shown). On the objective lens holder 2, the objective lens 1, the coil substrates 5a, 5b, the focusing coil 3, and the tracking coils 4a, 4b are respectively fixed at desired positions. Further, the lead terminals of the respective coils are soldered and fixed to the lands of the circuit patterns formed on the coil substrates 5a and 5b. 10 is a protector (protector member), and 11 is a protector mounting part provided on the upper surface of the objective lens holder. The protector 10 is a spherical member made of silicone rubber, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com