Automatic marking head replacing system for robot

An automatic replacement and marking head technology, applied in the field of marking head system, can solve the problems of production efficiency impact, influence on the improvement of automation, prolong downtime, etc., and achieve the effect of solving low efficiency, shortening downtime and improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and specific examples, but is not limited as the invention.

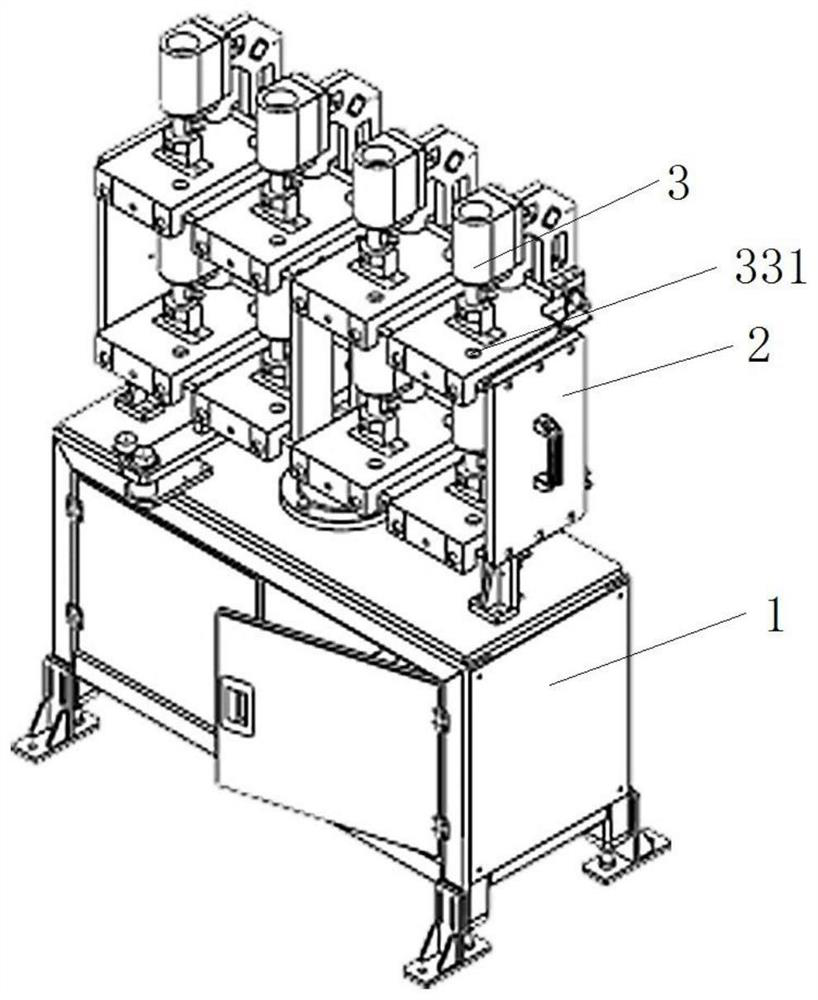

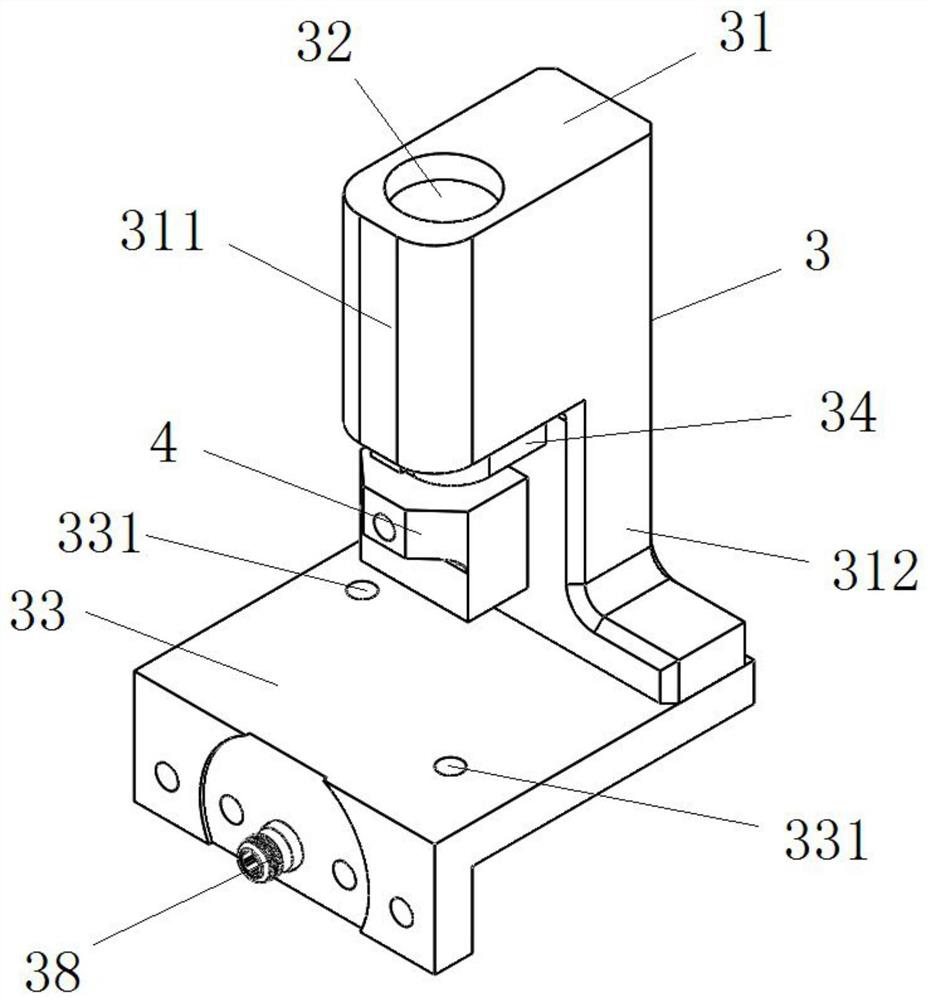

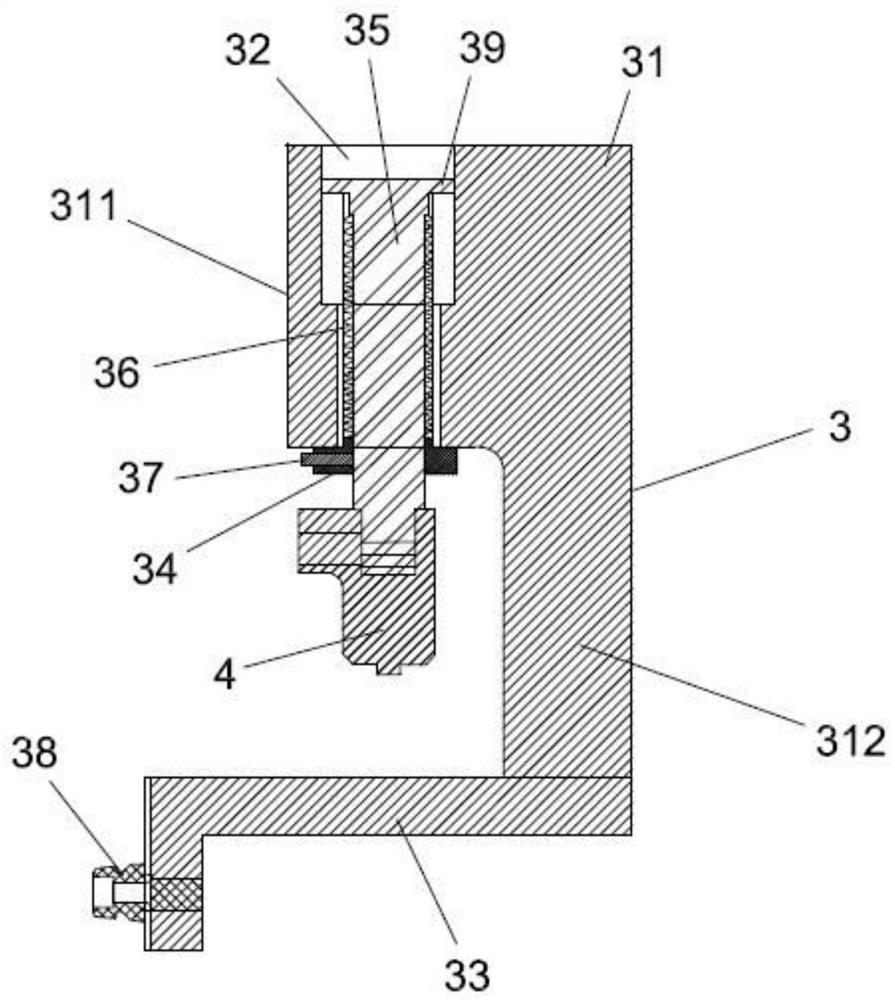

[0027] figure 1 It is a perspective view of the robot automatically replacing the header system in the present invention; figure 2 It is a perspective view of the taire head fast changing active end of the present invention; image 3 It is a schematic diagram of a sectional structure of a taist head fast-changing active end in the present invention. See Figure 1 to 3 As shown, a preferred embodiment is shown, and a robot showing a robot is automatically replaced, including a header character clamp 4, further comprising a character replacement turret 1, provided in the upper end of the character replacement The marking machine mounting the frame 2, and a number of tabs set on the marking machine mounting rack 2, each tamper snaps are provided with a header character clamp, respectively. 4, where the marking machine mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com