A high-precision head frame

A high-precision, headstock technology, which is applied in the direction of grinding frame, grinding drive device, manufacturing tools, etc., can solve the problems of unable to meet the high-precision requirements of shaft parts, unable to keep clean, low transmission accuracy, etc., to maintain Cleanliness, reduce the tolerance of axial movement, and ensure the effect of transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

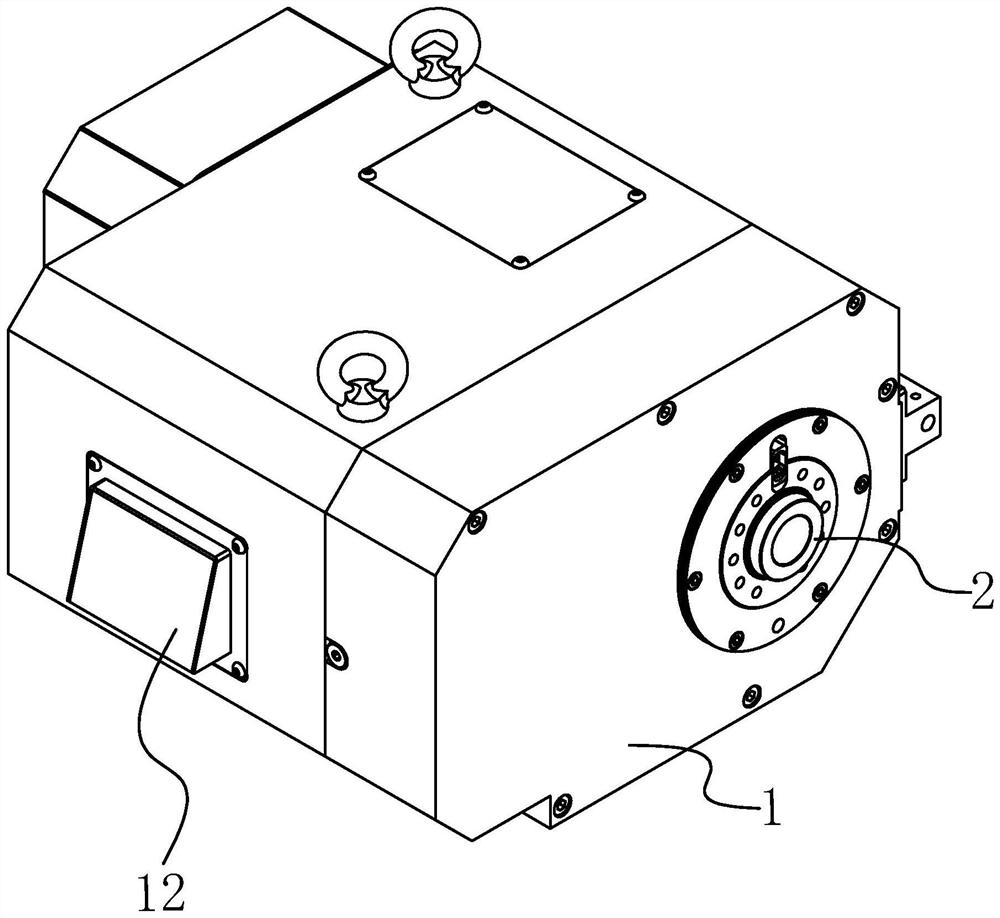

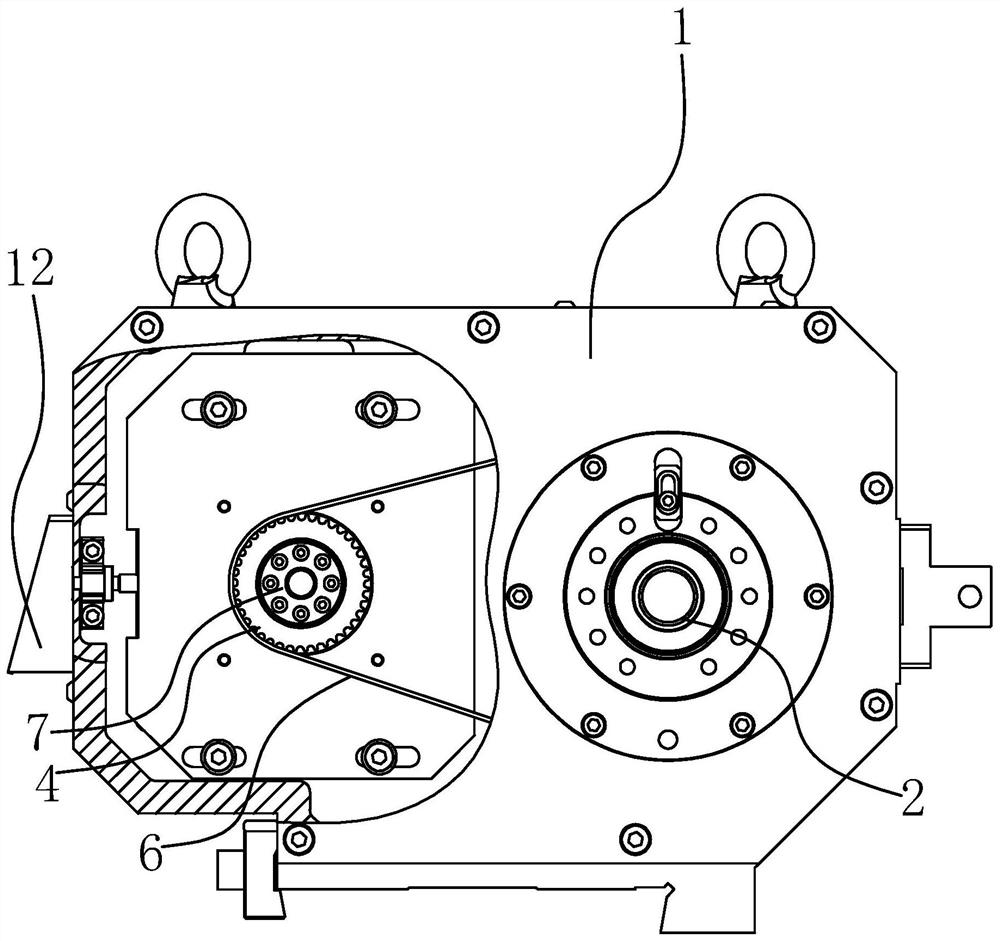

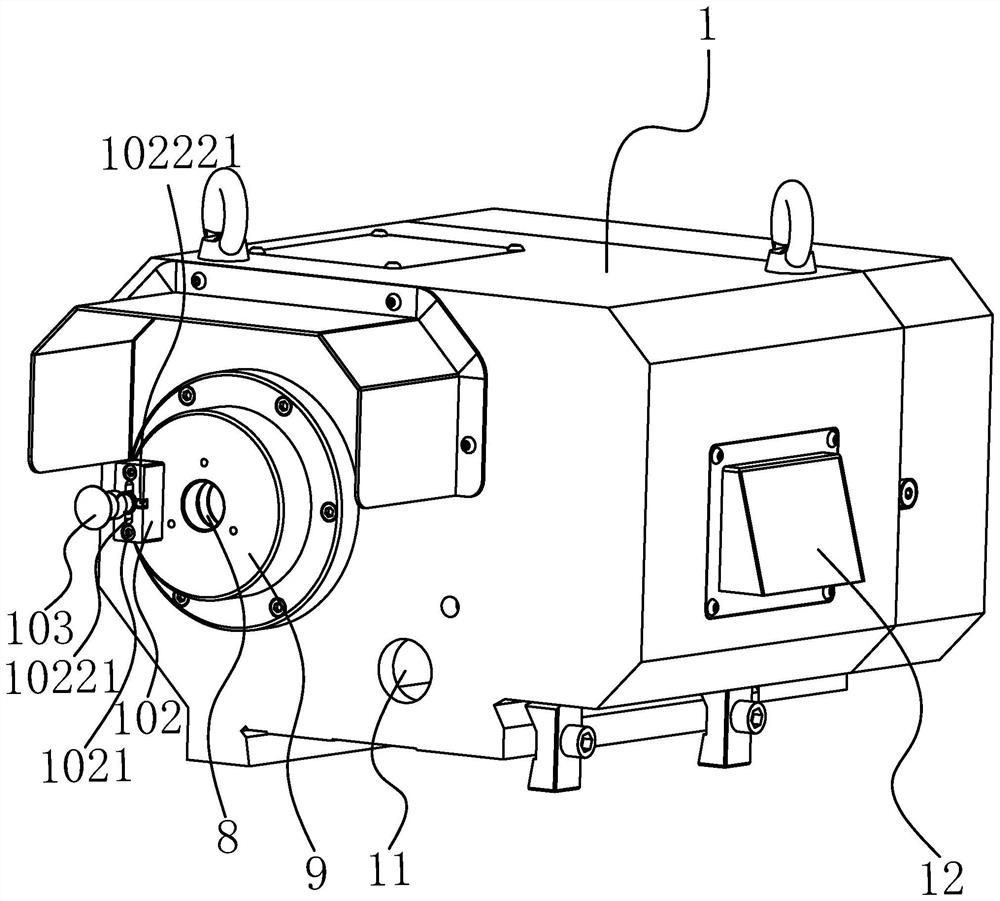

[0031] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0032] like Figure 1-5 As shown, the present invention includes a casing 1, a main shaft 2, a motor 3 is arranged in the casing 1, a motor synchronizing wheel 4 is arranged on the output shaft of the motor 3, a main shaft synchronizing wheel 5 is connected to the upper surface of the main shaft 2, and the main shaft synchronizing wheel 5 It is connected with the motor synchronous pulley 4 through the belt 6 .

[0033] The motor 3 drives the output shaft to drive the motor synchronous wheel 4 to rotate, the motor synchronous wheel 4 rotates to drive the belt 6 to drive, the belt 6 drives the spindle synchronous wheel 5 to rotate, the spindle synchronous wheel 5 rotates to drive the spindle 2 to rotate, and the motor 3 is arranged in the housing....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap