Method for preassembling impact type water distribution ring pipe

A water distribution ring and impact type technology, which is applied in the fields of hydroelectric power generation, hand-held tools, climate sustainability, etc., can solve the problem of low versatility of installation, and achieve the effect of improving work efficiency, good general performance, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

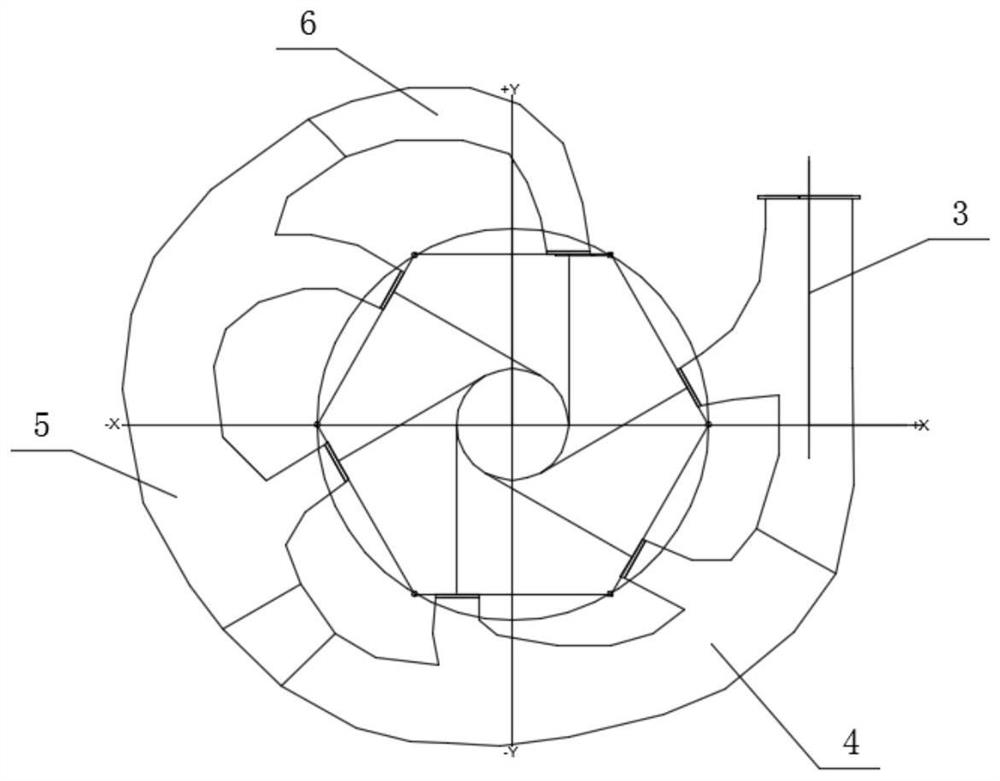

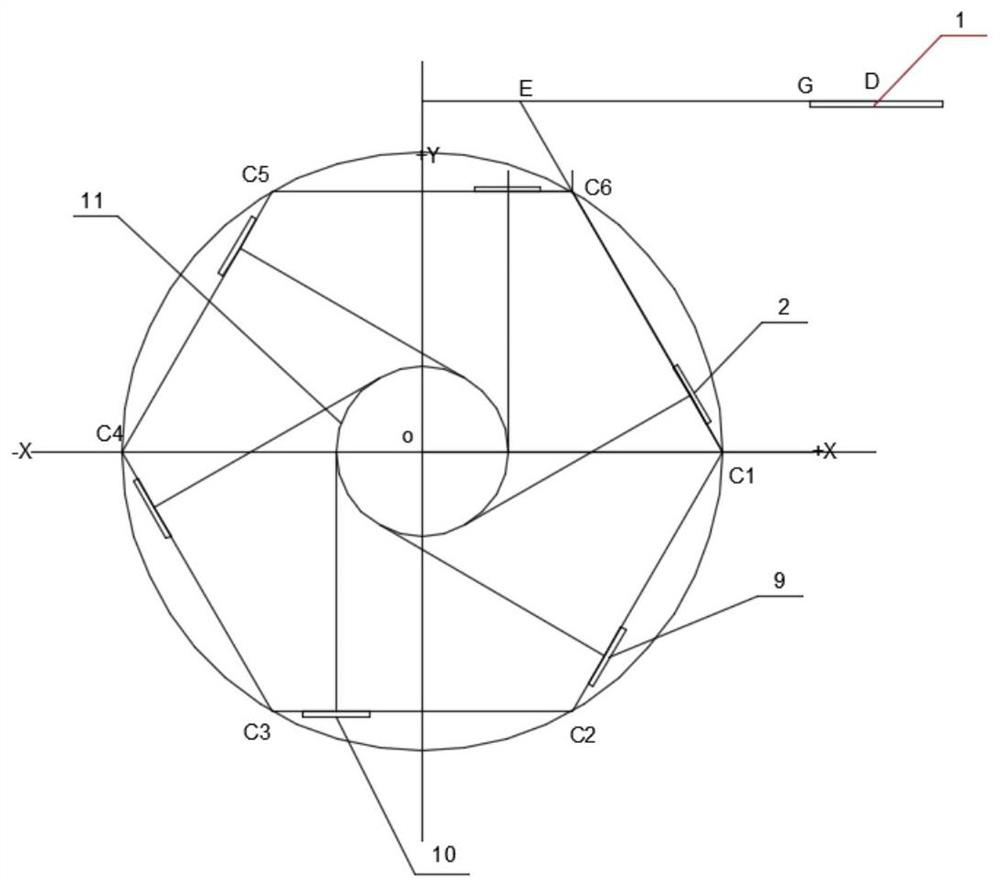

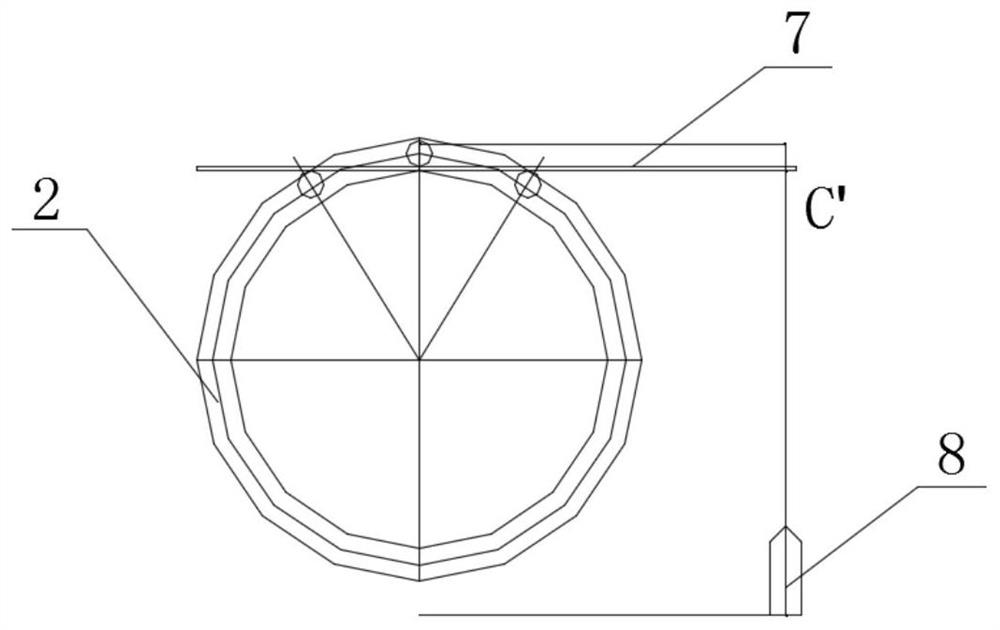

[0025] Such as figure 1 , figure 2 and image 3 As shown, a method for pre-installing the impact water distribution ring, specifically includes the following steps:

[0026] Step 1. Plan the pre-installation site: the site is equipped with ground rails, and T-nut installation grooves are installed on the ground rails to facilitate the topping, pressing and fixing of the position and shape of the ring pipe in the later stage;

[0027] Step 2. Preparation and scribing: prepare 6 sets of 5-thread high-precision (within 5-meter error less than 2mm) laser levels, 1 set of leveling instruments, several jacks of different sizes as needed (more than ten), 50 pieces of backing plates and wedges each ( can be borrowed and recycled), and several auxiliary scales 7; a center of circle is set in the middle of the field, and the jet pitch circle 11 of the runner is drawn according to the center of the circle. The center line of the nozzle flange 2 is tangent to the jet pitch circle 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com