Transfer device special for excavator manufacturing process

A technology of manufacturing process and transfer device, applied in the direction of hoisting device, etc., can solve the problems affecting the quality of excavator machine assembly, excavator machine performance, surface paint damage at the bottom of the boom, and increase post-processing costs, etc., to achieve manufacturing Low cost, good general performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

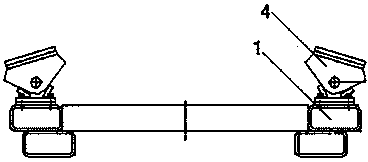

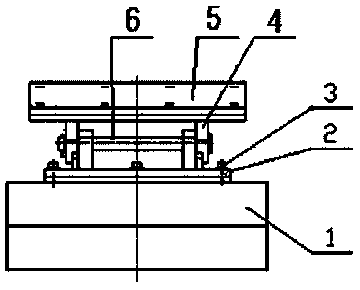

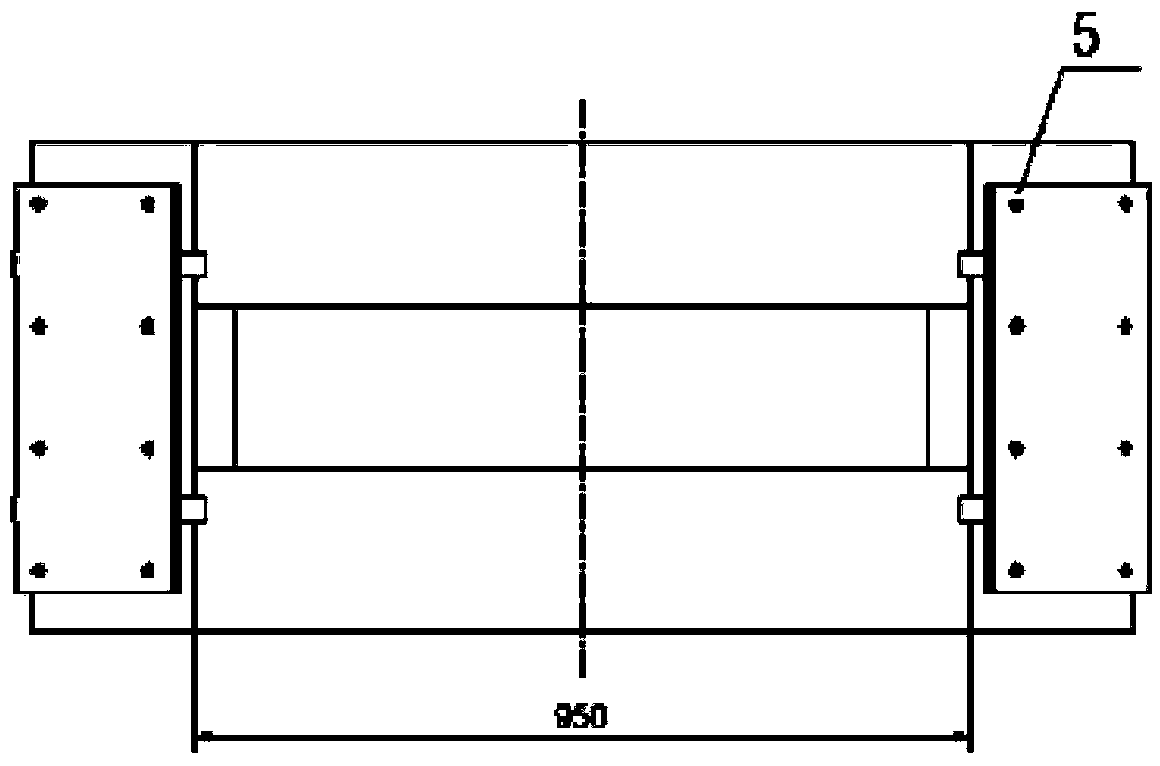

[0014] Such as figure 1 As shown, this embodiment is a special transfer device applied to the excavator manufacturing process. The special operation device includes a forklift base 1, a connection assembly and a support assembly, and the connection assembly is arranged on the fork Between the base 1 and the support assembly, the support assembly is movably connected with the connection assembly, and the support assembly can rotate relative to the connection assembly. The above-mentioned technical solution proposed by the present invention creatively improves the transfer device in the prior art, and sets a special operation device dedicated to the transfer of the arm of the excavator; the device includes a forklift base 1, a connection assembly and a support assembly become. The effect of described forklift base 1 is to carry out forklift in order to operate forklift conveniently, and this forklift base is the base with excellent versatility, can match the work with various t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com