Energy-saving automatic vertical curing oven

A curing furnace, automatic technology, applied in the field of energy-saving automatic vertical curing furnace, can solve the problems of inconvenient container clamping, inconvenient import and export protection, inconvenient adjustment of the length of the conveyor frame according to needs, etc., to achieve the effect of increasing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

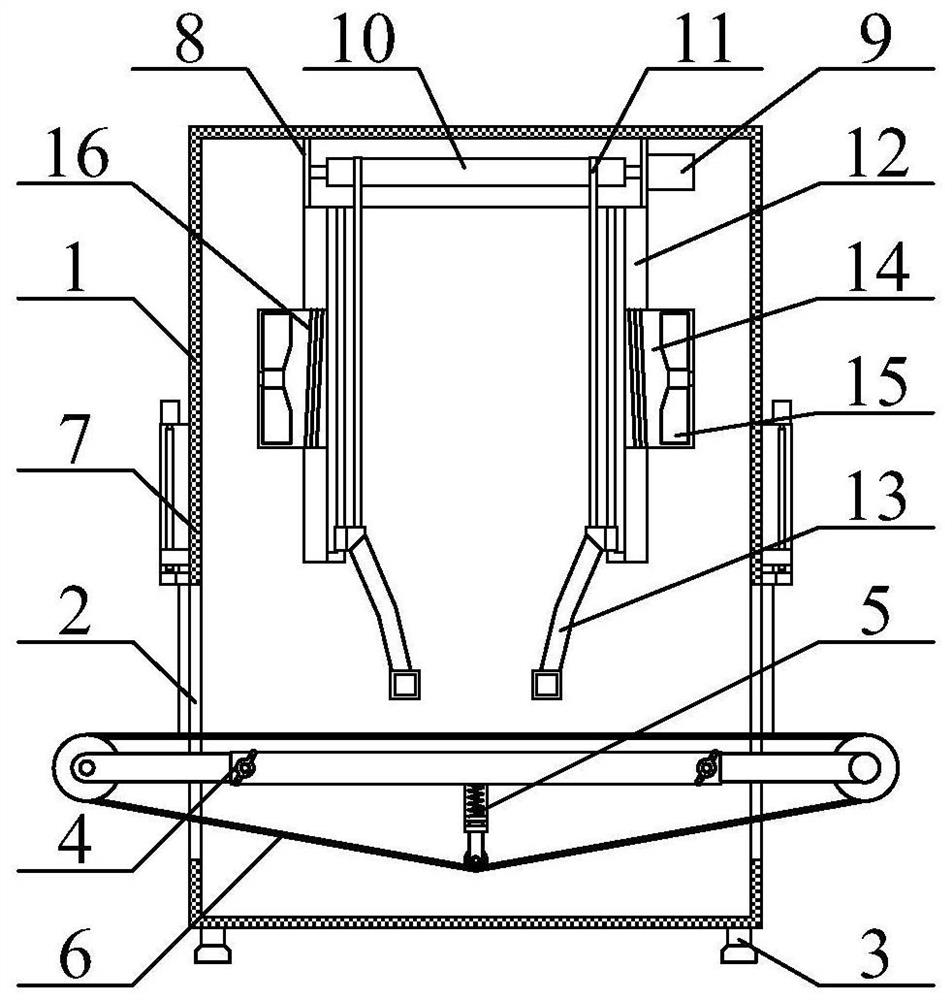

[0039] as attached figure 1 And attached figure 2 shown

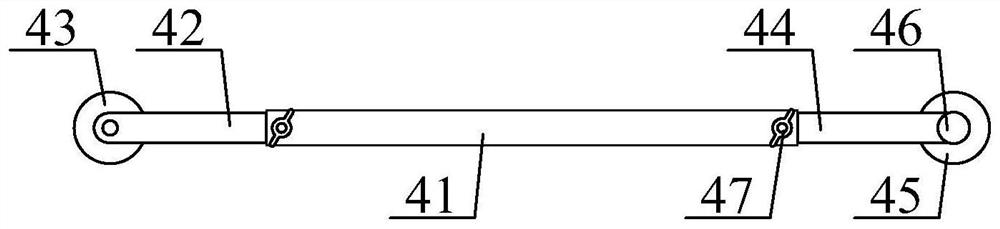

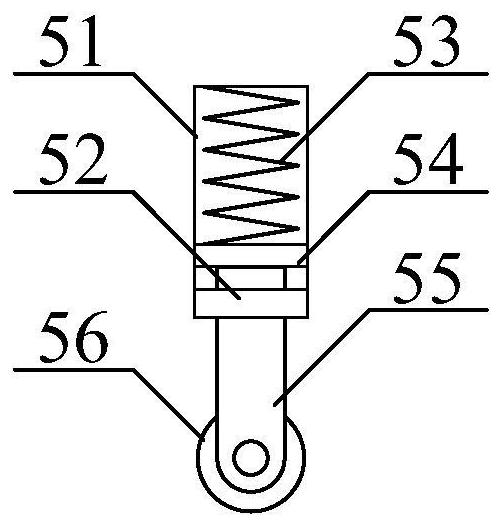

[0040]The invention provides an energy-saving automatic vertical curing furnace, which includes an outer frame 1, an inlet and outlet frame 2, a bottom bracket 3, an adjustable drive frame structure 4, a buffer top tension frame structure 5, a conveyor belt 6, an adjustable protective frame structure 7, Installation frame 8, winding motor 9, winding roller 10, lifting rope 11, longitudinal mounting frame 12, adjustable clamping frame structure 13, fan frame 14, blower 15 and electric heating tube 16, and the inlet and outlet frame 2 is embedded in the outer frame The left and right sides of the lower part of 1; the bolts of the bottom bracket 3 are installed at the four corners of the lower part of the outer frame 1; the adjustable driving frame structure 4 is installed on the inner lower part of the outer frame 1; In the middle and lower part of the adjustable driving frame structure 4; the adjustable protective fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com