Torque measuring device based on motor manufacturing

A technology of torque measurement and electric motors, applied in the direction of measuring devices, torque measurement, manufacturing tools, etc., can solve problems such as random start-up, safety accidents, inability to realize torque detection and other detection, so as to improve convenience and avoid safety The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

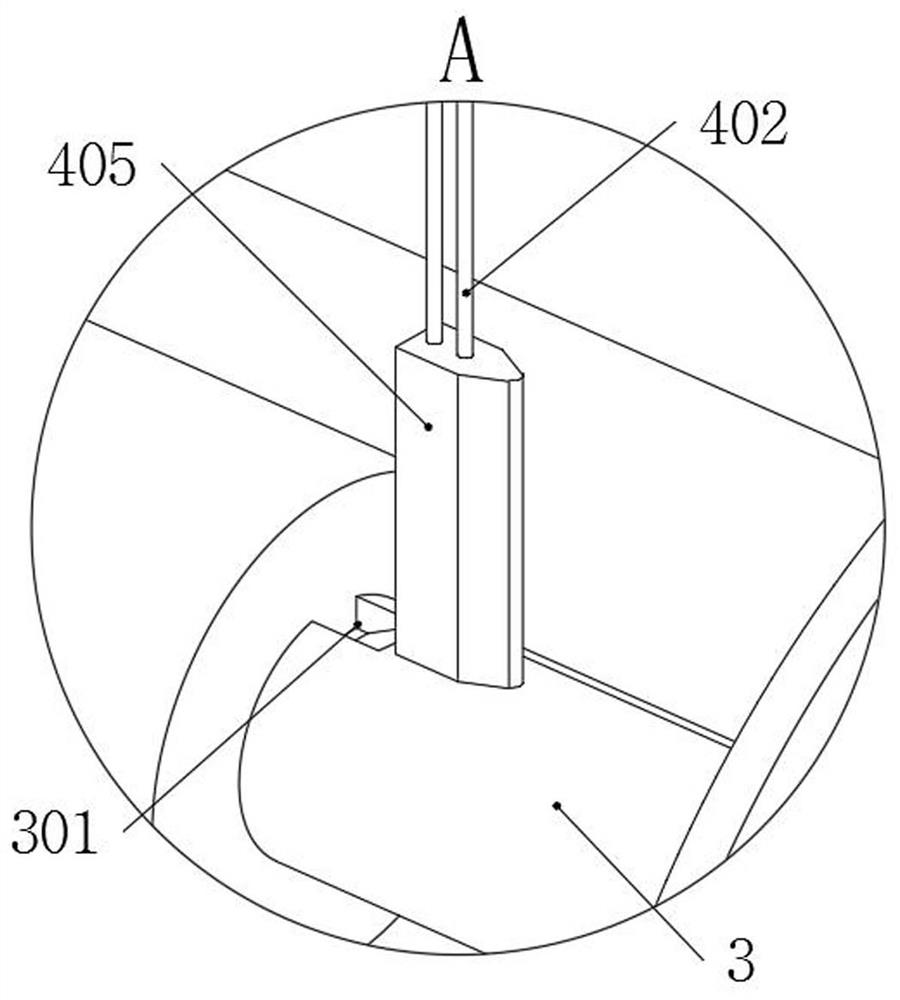

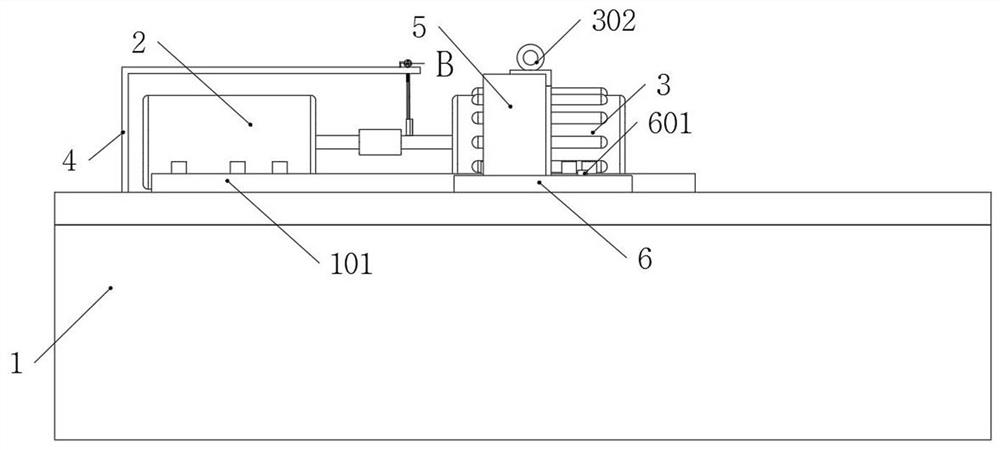

[0039] Example: Please refer to Figure 1 to Figure 9 :

[0040]The present invention proposes a torque measurement device based on motor manufacturing, including: a workbench 1, an auxiliary part 4, a locking part 5 and a control box 6; the workbench 1 is placed on the ground, and the workbench 1 is fixedly connected by bolts There is a detector 2, and a drive motor 3 is placed on the workbench 1; a suspension ring 302 is installed on the drive motor 3; the auxiliary part 4 is composed of a mounting arm 401, a sliding rod 402, a retaining ring 403, an elastic member 404, a contact block 405, a contact Board 406, mounting seat A407, indicator light 408 and contact switch 409, and mounting arm 401 is fixedly connected to workbench 1 by bolts; mounting arm 401 is slidably connected with two sliding rods 402, and one sliding rod on the left A retaining ring 403 is welded on the 402, and an elastic member 404 is sleeved on a sliding rod 402 on the left side; the tail ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com