An automated testing device for a semiconductor device

An automated testing and semiconductor technology, which is applied in semiconductor/solid-state device testing/measurement, measuring devices, components of electrical measuring instruments, etc., and can solve problems such as cumbersome detection of refrigeration chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

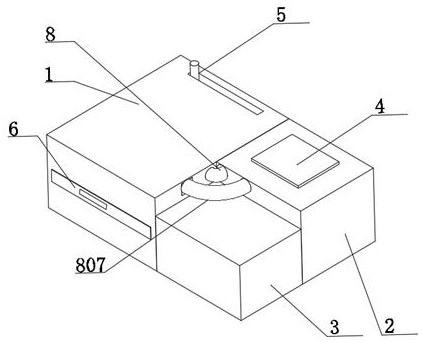

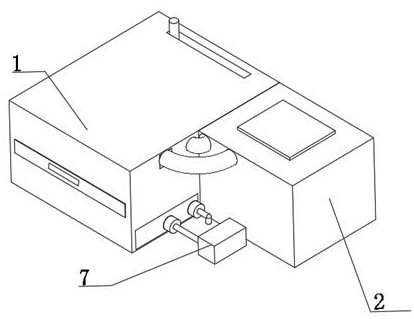

[0038] Such as Figure 1-13 As shown, an automated testing device for a semiconductor device includes a chassis 1, a conductive socket 9 is provided on one side of the chassis 1, a conductive component 8 and a current output control component 5 are arranged inside the upper side of the chassis 1, and the chassis 1 One side of 1 is fixedly connected to a temperature measuring box 2, and a digital display thermometer 4 is fixedly installed on the upper side of the temperature measuring box 2, and a water tank 3 is fixedly connected to the side of the chassis 1 close to the temperature measuring box 2, and inside A temperature guide assembly 7 is provided, a fixed assembly 6 is fixedly installed inside the cabinet 1, a conduction assembly 8 is fixedly installed inside the upper side of the cabinet 1, two electric push rods 610 are fixedly installed inside the cabinet 1, two The output ends of the electric push rods 610 are respectively fixedly connected with a docking assembly 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com