A working electrolytic chamber device with temperature control

A technology of temperature control and electrolysis chamber, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of low control precision, difficult fixation, and many faults, and achieve the effect of simple device structure, easy temperature control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

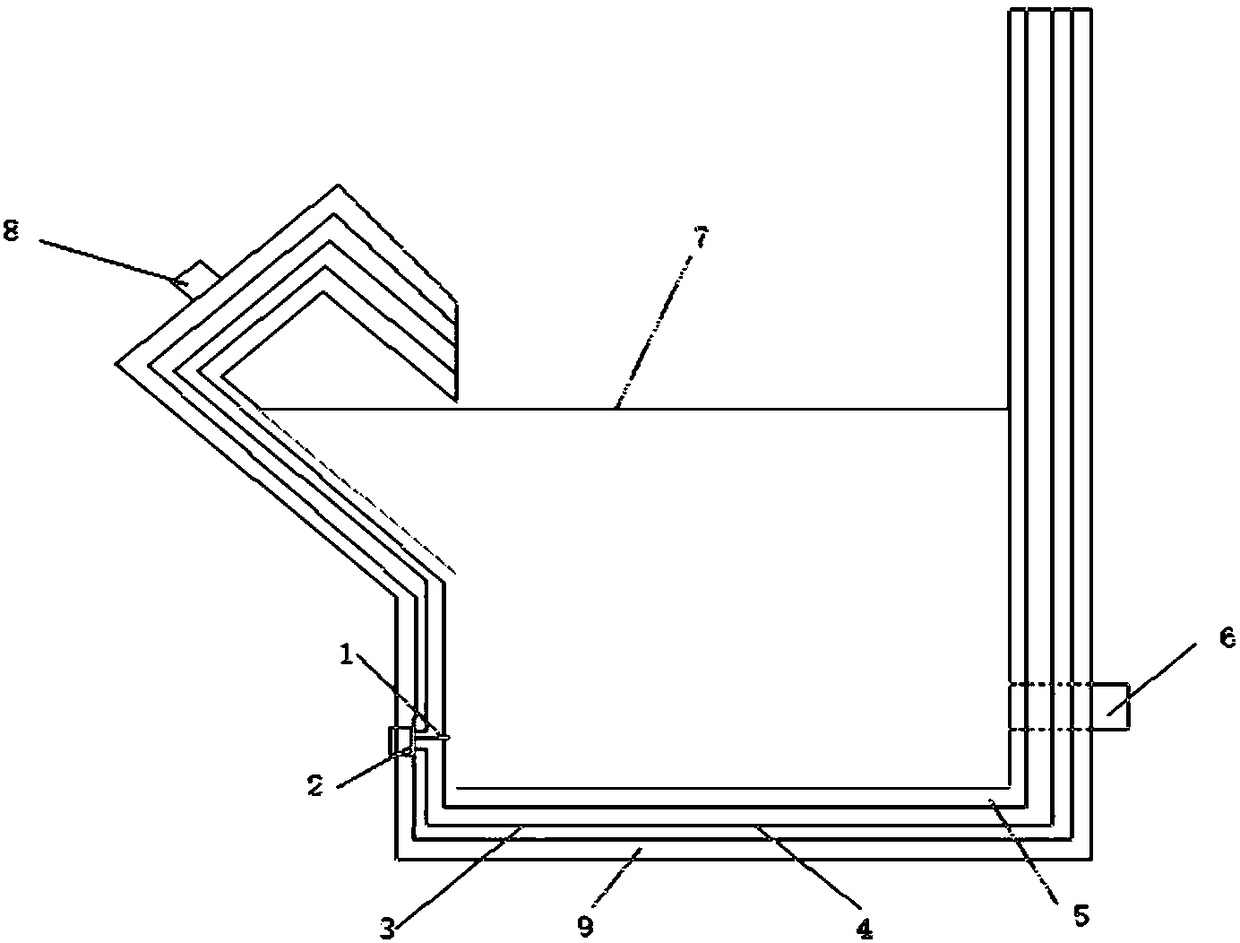

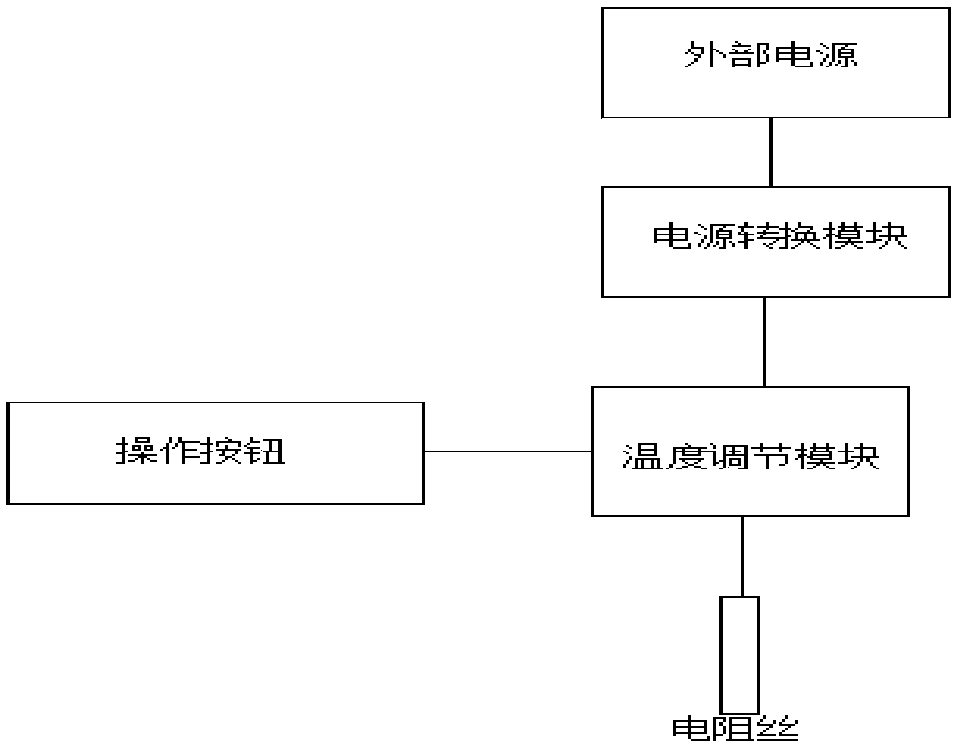

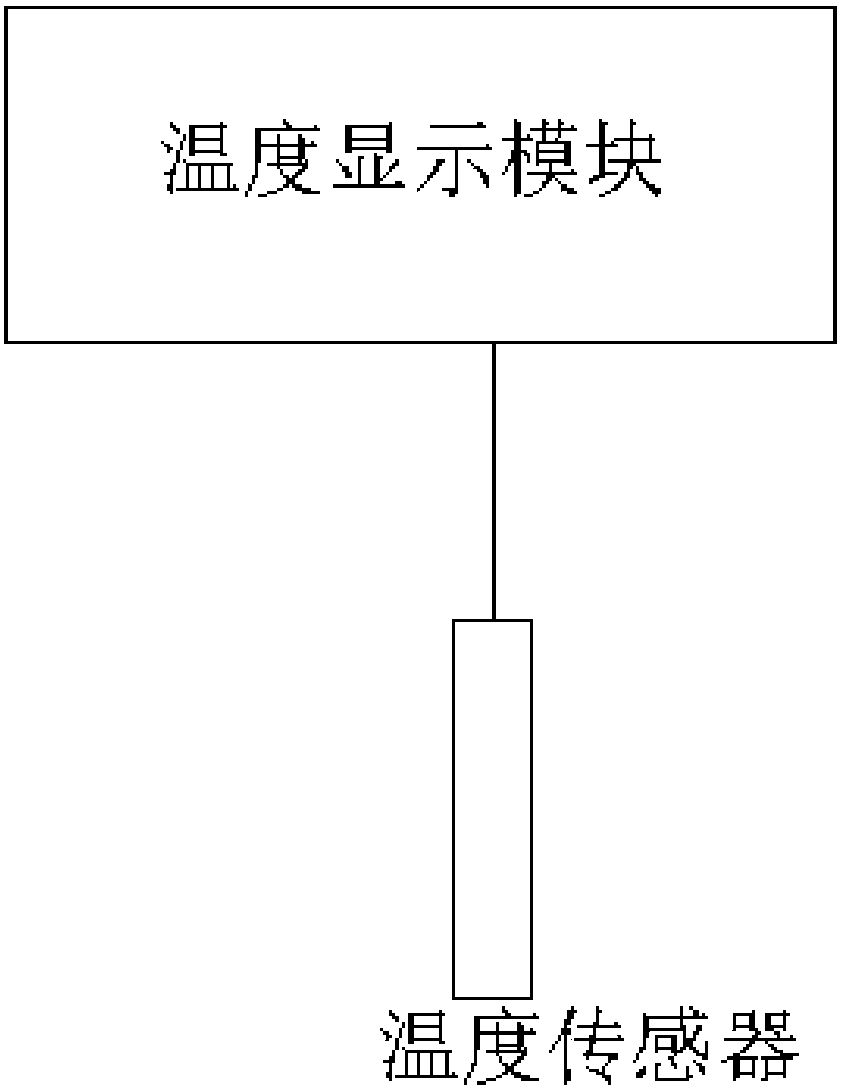

[0028] Such as Figure 1~5 As shown, a working electrolytic chamber device with temperature control includes temperature sensor 1, electrical component installation hole 2, heating resistor 3, interlayer one 4, interlayer two 5, auxiliary electrode pool interface 6, electrolyte solution 7, measuring electrode installation Hole 8, interlayer three 9, the working electrolysis chamber has interlayer one 4, interlayer two 5, interlayer three 9, electrical component installation hole 2, auxiliary electrode pool interface 6 and measuring electrode installation hole 8; described interlayer one 4 There is a heating resistor 3 inside, the interlayer 2 5 is filled with a heat transfer medium and a temperature sensor 1 is installed, and the interlayer 3 9 is filled with heat insulating material.

[0029] Further work, the inner wall of the electrolytic chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com