Rotary 18-nozzle jet flow cross-shaped spray head

A rotary and cross-shaped technology, applied in the direction of spraying devices, spraying devices with movable outlets, chemical instruments and methods, etc., can solve the problems of inability to adjust, single function, inconvenient use, etc., to improve the striking force and strengthen the striking force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

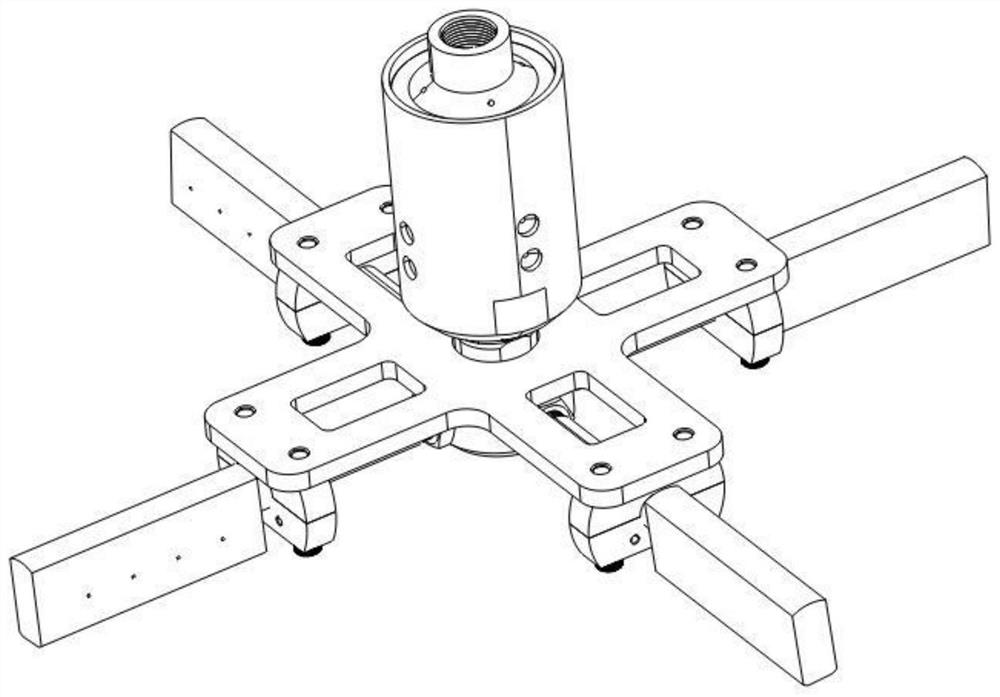

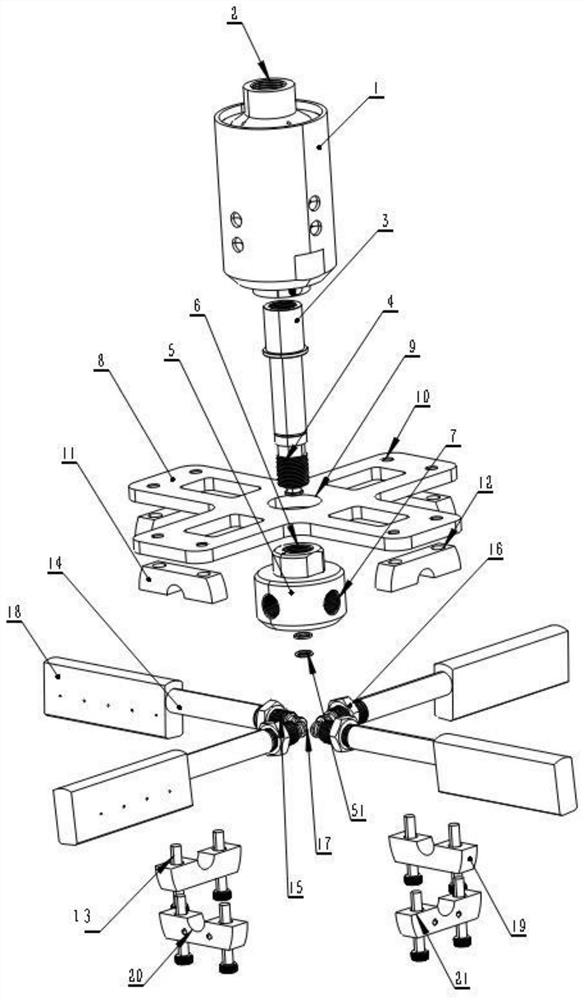

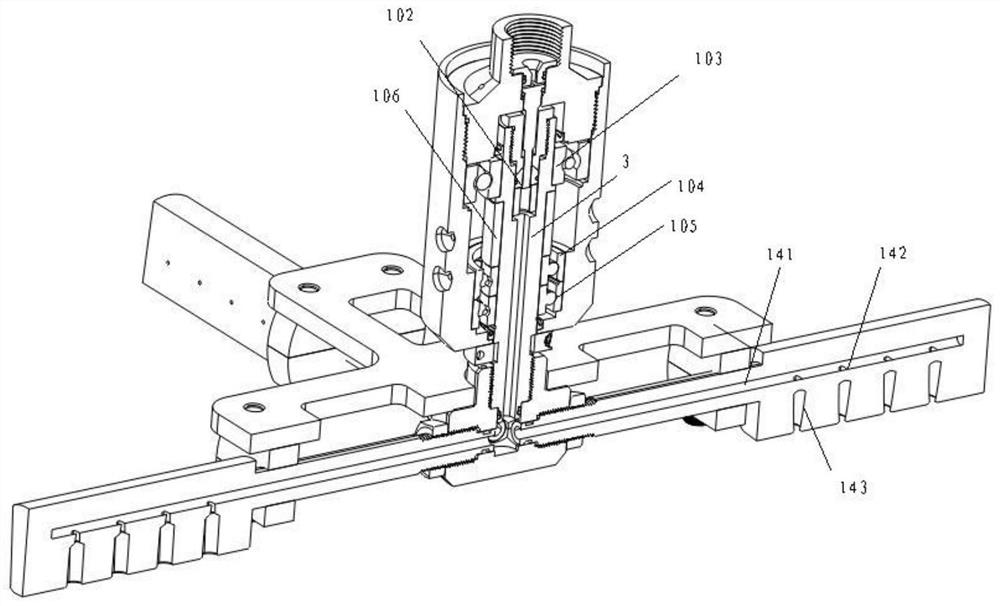

[0020] Such as Figure 1 to Figure 5 As shown, the present invention discloses a rotary 18-nozzle jet cross-shaped spray head. The technical solution adopted is to include a rotating body shell 1, a water inlet 2, a rotating shaft 3, a rotating shaft stabilization structure, a water outlet 4, and a rotating mounting ring 5 , installation ring sealing ring 51, water inlet joint 6, water outlet joint 7, cross mounting frame 8, through hole 9, installation hole 10, stable installation structure, water spray rod 14, water spray rod joint 15, angle adjustment structure, joint seal Ring 17, cutter head 18 and water spray structure, external high-pressure water enters the rotating shaft 3 installed inside the rotating body shell 1 through the water inlet 2, and the rotating shaft 3 is provided with a rotating shaft stabilization structure during installation to ensure its stable installation At the same time, it can be rotated again. The lower part of the rotating shaft 3 is threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com