A round pipe trimming equipment for building construction

A technology for building construction and round pipes, which is applied in the field of round pipe edge trimming equipment, and can solve the problems of round pipe deformation, shape, difficulty in ensuring a neat cut, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

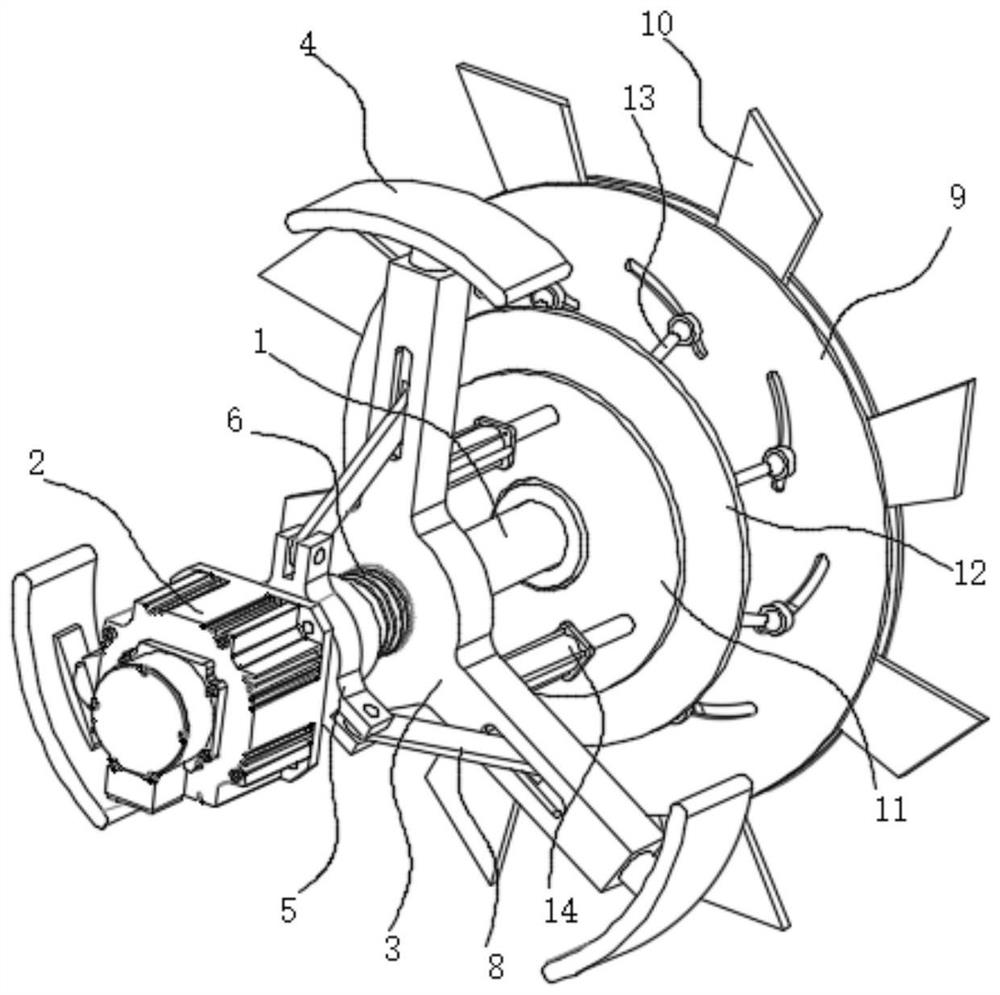

[0031] see figure 1 , in an embodiment of the present invention, a round pipe edge trimming device for building construction includes a main shaft 1, a support frame 3 is rotatably arranged in the main shaft 1, and one end of the main shaft 1 is connected to the support frame 3 in the output end of the fixedly connected motor 2;

[0032] The outer circumference of the support frame 3 is distributed with a plurality of arc-shaped support pieces 4, and the support pieces 4 can be supported into the inner wall of the circular tube;

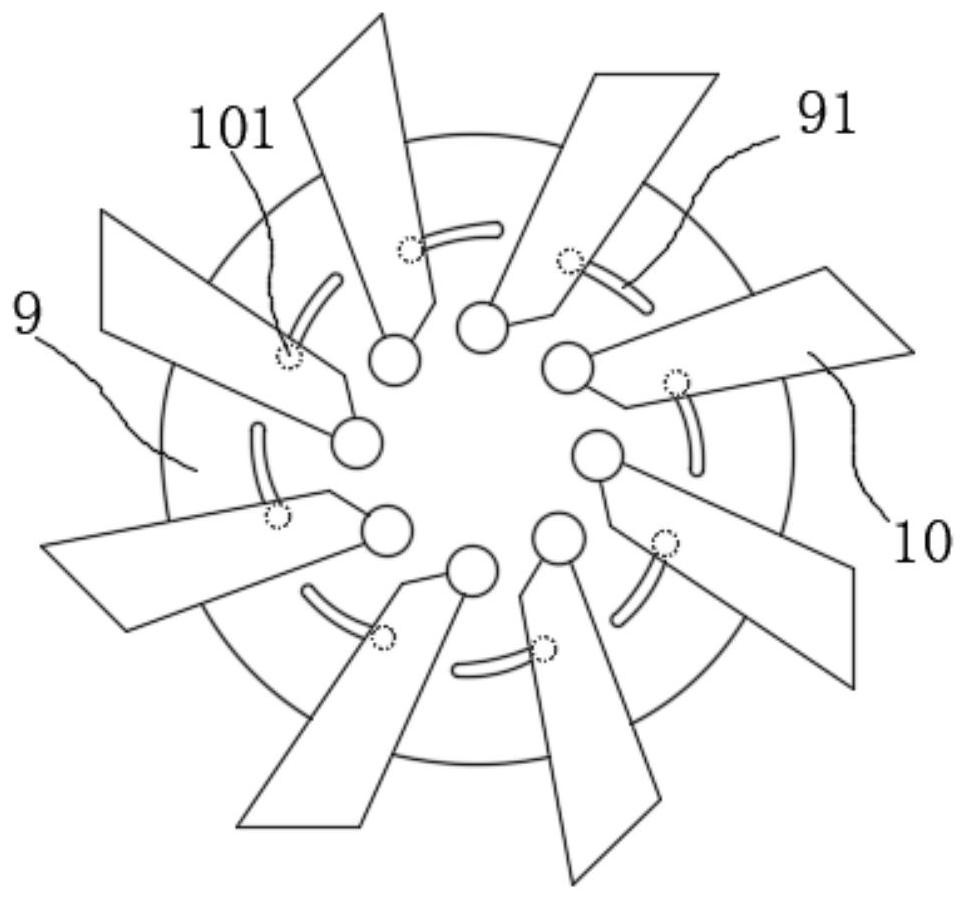

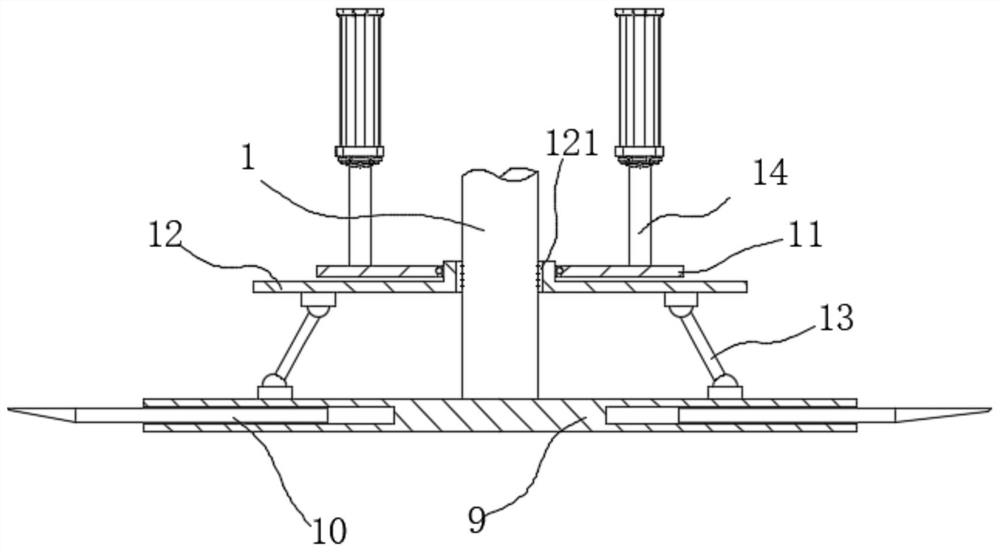

[0033] The end of the main shaft 1 away from the motor 2 is fixed with a turntable 9 , and a plurality of cutting knives 10 are distributed around the outer circumference of the turntable 9 .

[0034] see figure 2 , in this embodiment, there are a plurality of support rods 41 that can move radially along the circumference of the support frame 3, the support piece 4 is fixedly connected to the outward end of the support rod 41, and the support fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap