Improved intelligent desktop 3D printer

A 3D printer and improved technology, applied in the field of smart desktop 3D, can solve the problems of decreased printing efficiency, reduced printing speed, slow wire replacement speed, etc., to solve the effect of wire waste and avoid jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

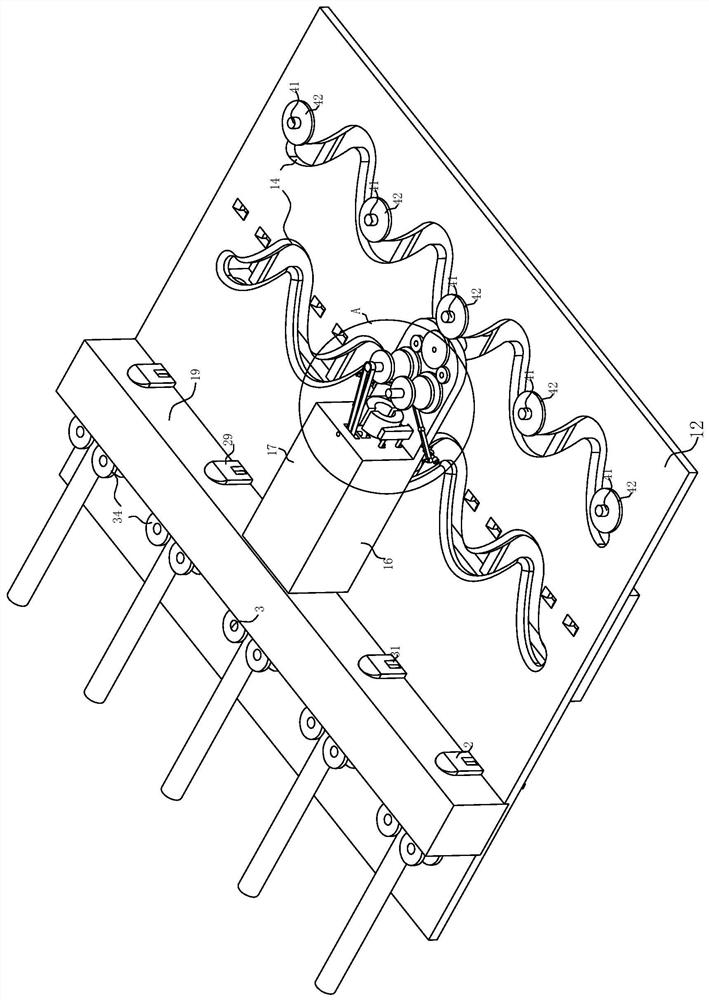

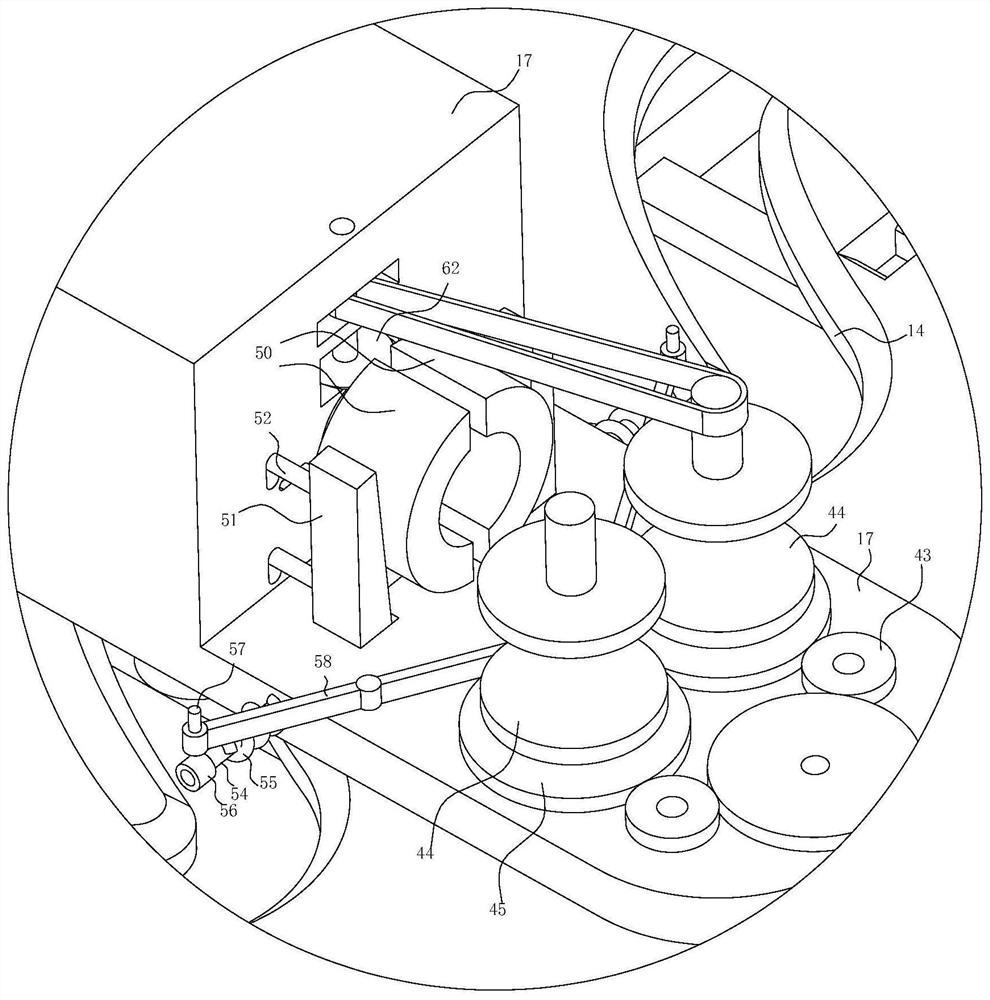

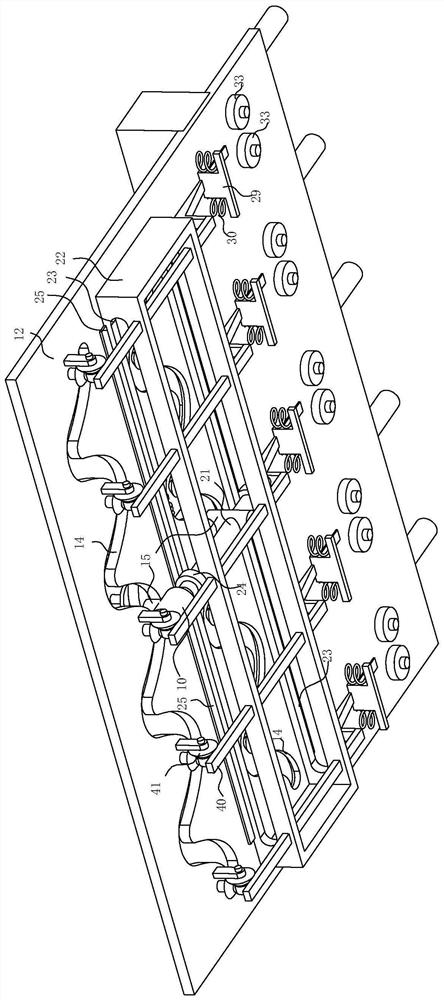

[0034] see Figure 1-9 , the present invention provides a technical solution: an improved intelligent desktop 3D printer, including a motor 10, an electromagnetic rod 11, a mounting plate 12 and a connector 13, two groups of parallel wave grooves 14 are opened on the upper end of the mounting plate 12, two The inner wall of the wave groove 14 is slidingly provided with parallel rods 15, and the upper ends of the two parallel rods 15 are fixedly provided with the same stepping mechanism 16. The block 17 is fixedly arranged on the upper ends of the two parallel rods 15, the middle of the bridging block 17 is provided with a feeding hole 18, the rear end of the feeding hole 18 is large and the front end is small, and the inner wall of the bridging block 17 surrounds the feeding hole 18 and the side wall is fixedly provided with a connector 13 , the upper end of the mounting plate 12 is fixedly provided with a branching block 19, and the side wall of the branching block 19 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com