Sterile sealing equipment for producing disposable sterile double-lumen bronchial cannula

A technology of sealing equipment and bronchi, which is applied in the directions of packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of insufficient sealing and low work efficiency, and achieve the effect of improving tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

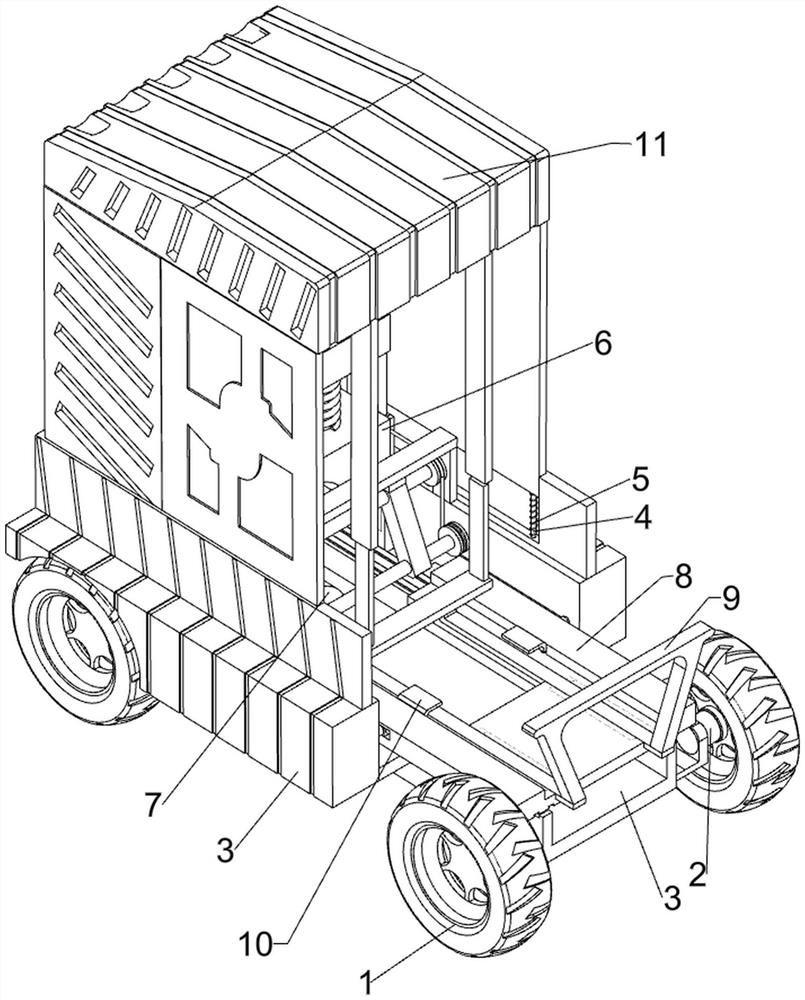

[0080] A sterile sealing device for the production of disposable sterile double-lumen endobronchial tubes, such as Figure 1-4 Shown, comprise wheel 1, connecting rod 2, place plate 3, the first limit rod 4, the first spring 5, press down mechanism 6 and sealing mechanism 7, place plate 3 left and right sides all front and back symmetrical rotation type connections have The connecting rod 2 is connected with the wheel 1 on the connecting rod 2, and the left and right sides of the placing plate 3 are symmetrically provided with the first limit rod 4, and the placing plate 3 is provided with 4 first springs 5, and the first springs 5 are respectively Covered on the first limit rod 4 , the placing plate 3 is provided with a pressing mechanism 6 , and a sealing mechanism 7 is connected between the pressing mechanism 6 and the placing plate 3 .

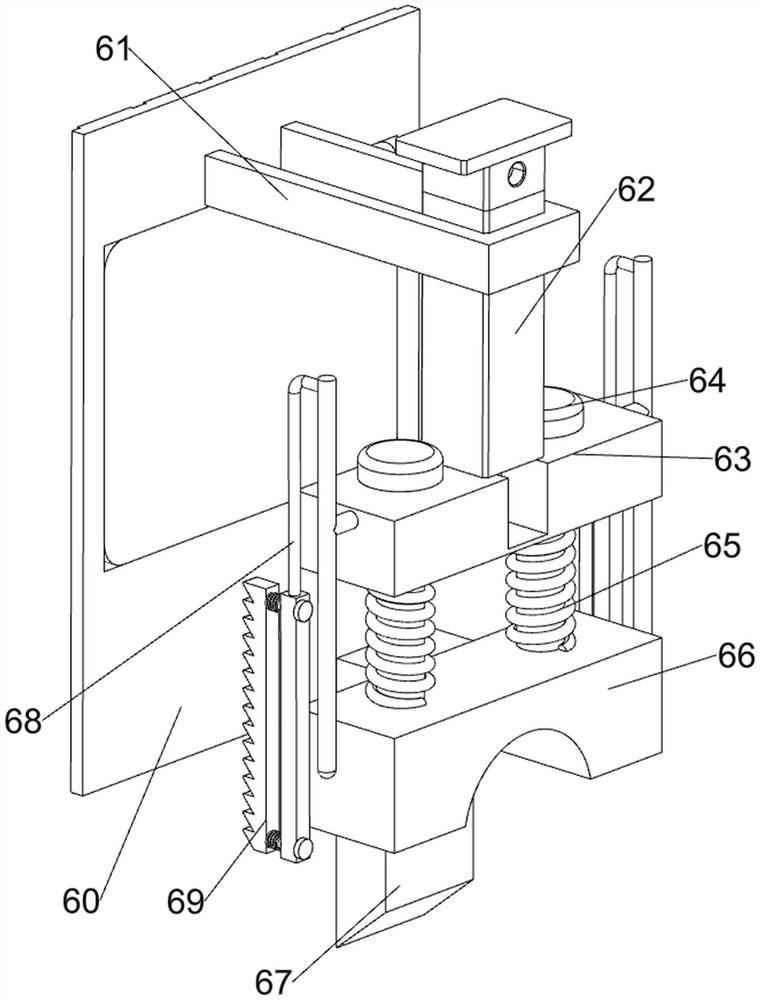

[0081] The pressing mechanism 6 includes a front baffle plate 60, a first fixing plate 61, a cylinder 62, a first connecting plate 63, ...

Embodiment 2

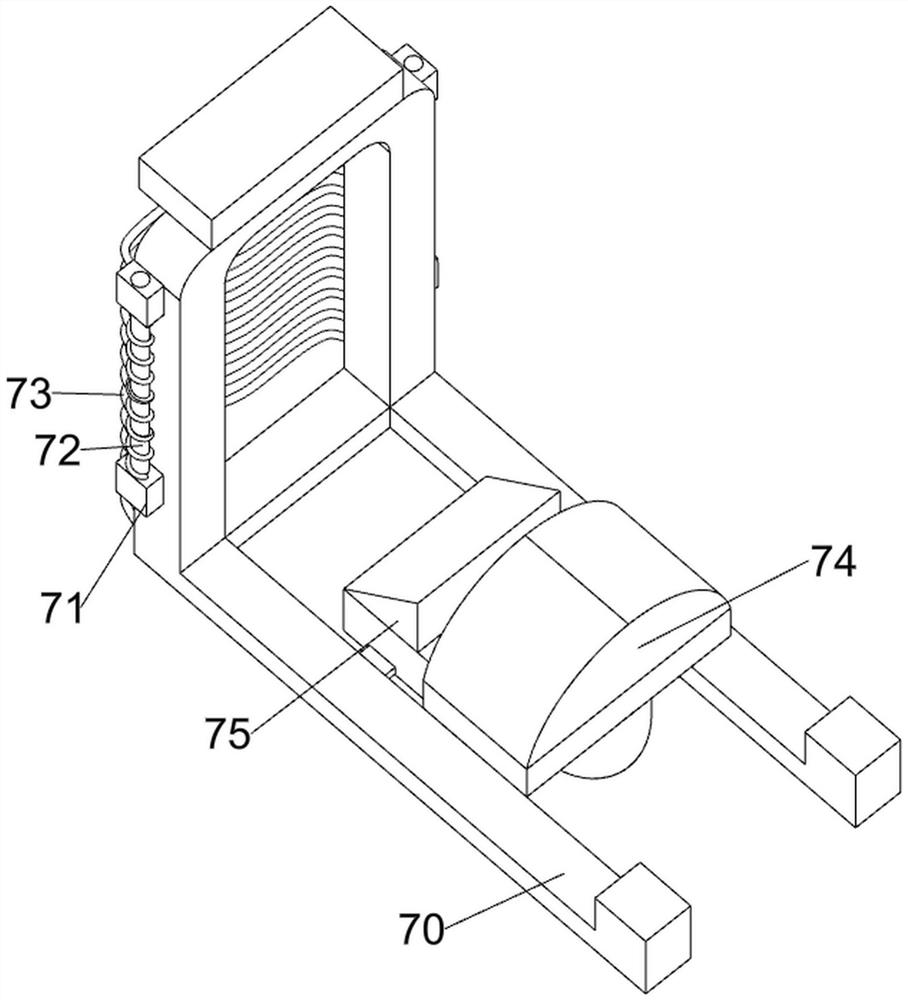

[0085] On the basis of Example 1, such as Figure 5-9 As shown, an automatic material pushing mechanism 8 is also included, and the automatic material pushing mechanism 8 includes a first sliding plate 80, a fifth limit rod 81, a fifth spring 82, a second connecting block 83, a traction rope 84, a reel 85, fixed rod 86, the third fixed plate 87, slide rail 88 and the third connecting block 89, the top of the placement plate 3 is slidingly connected with the first sliding plate 80, and the connection between the first sliding plate 80 and the placement plate 3 is elastic Parts, the middle part of the first sliding plate 80 is symmetrically provided with the fifth stop rod 81, the front side of the fifth stop rod 81 is slidably connected with the second connecting block 83, and the rear side of the second connecting block 83 is connected with the first sliding block. The fifth spring 82 is connected between the plates 80, the top of the placement plate 3 is provided with a third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com