Intermittent feeding device for compound fertilizer production

An intermittent, compound fertilizer technology, applied in the direction of mixers, solid materials, mixers with rotating stirring devices, etc., can solve the problems of large resistance of the stirring rod, manual bagging, slow mixing rate of raw materials, etc., and achieve a reasonable structure The effect of simplicity, low production cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

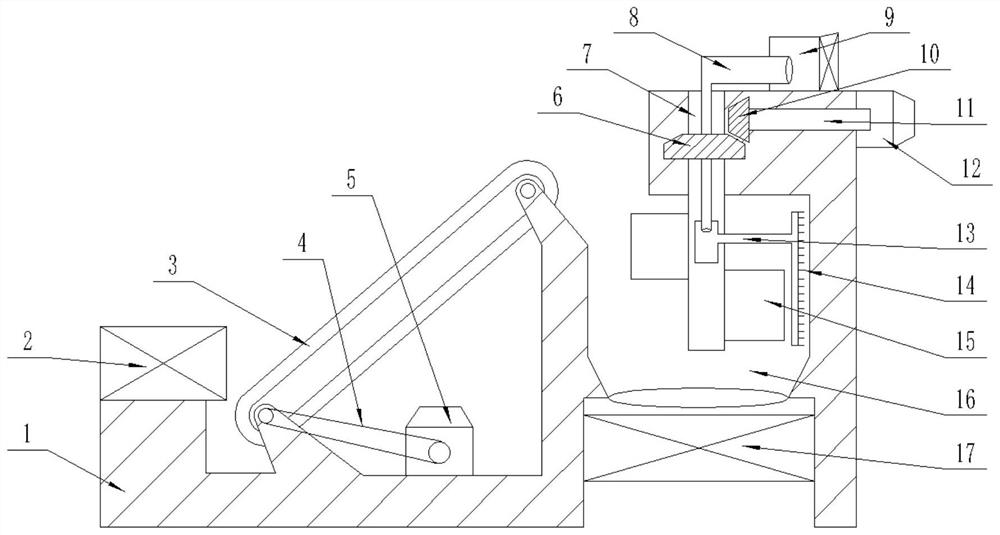

[0020] like figure 1 As shown, this specific embodiment adopts the following technical solutions: an intermittent feeding device for compound fertilizer production, including a device frame 1, an intermittent device 2, a conveyor belt 3, a belt 4, a first motor 5, a first gear 6, a hollow rod 7, trachea 8, air pump 9, second gear 10, gear rod 11, second motor 12, hollow brush rod 13, hair brush 14, stirring blade 15, discharge port 16 and discharging bag sealing device 17; The lower end of the right side of the device frame 1 is provided with a material discharge sealing device 17, and the upper end of the discharge sealing device 17 is provided with a discharge port 16; the left side of the device frame 1 is provided with an intermittent device 2; A conveyor belt 3 is provided; the middle lower end of the device frame 1 is provided with a first motor 5, and the output end of the first motor 5 is connected with the input end of the left end of the conveyor belt 3 through a bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com