Heat preservation belt winding equipment for petroleum conveying pipeline

A technology for oil conveying and thermal insulation belts, which is applied to devices and coatings that apply liquid to the surface. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

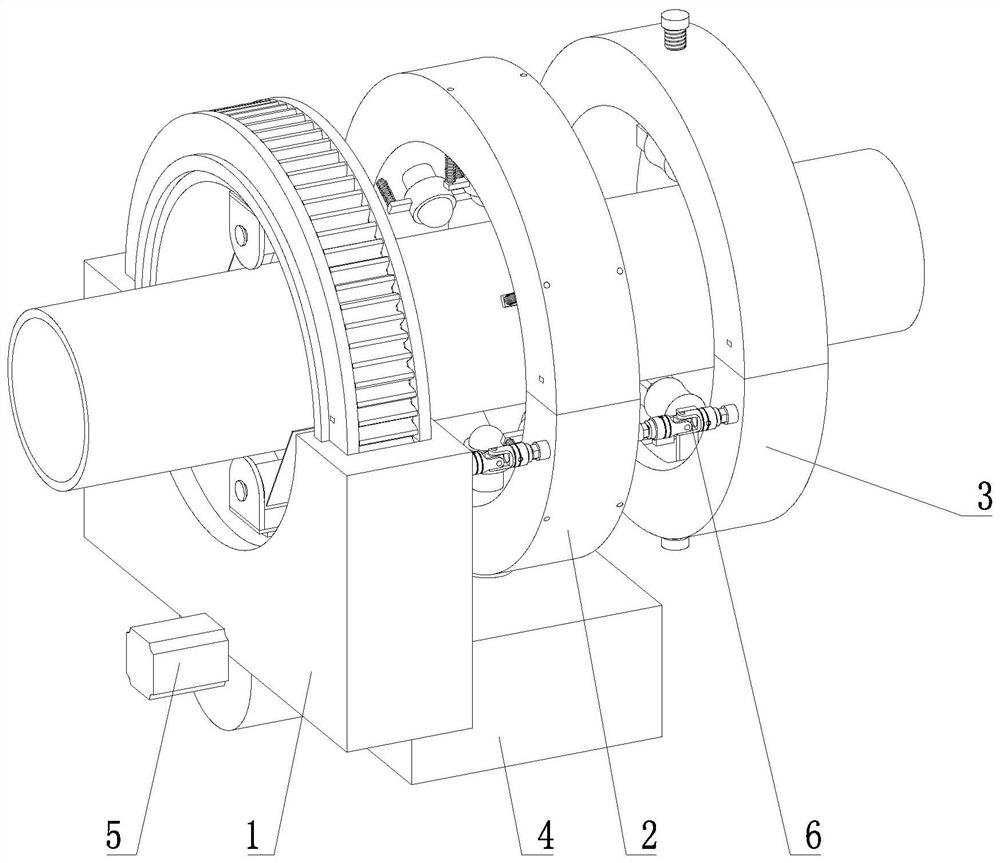

[0040] Such as figure 1 As shown, the present invention proposes a thermal insulation tape winding device for oil pipelines, including a winding assembly 1, a glue assembly 2 and a connecting assembly 6;

[0041] The winding assembly 1 is provided with an automatic glue-feeding assembly 4, the glue-making assembly 2 is connected with the winding assembly 1 through the connection assembly 6, and the glue-making assembly 2 is connected with the automatic glue-feeding assembly 4; the moving assembly 3 is connected with the glue-making assembly through the connection assembly 6 2 connections;

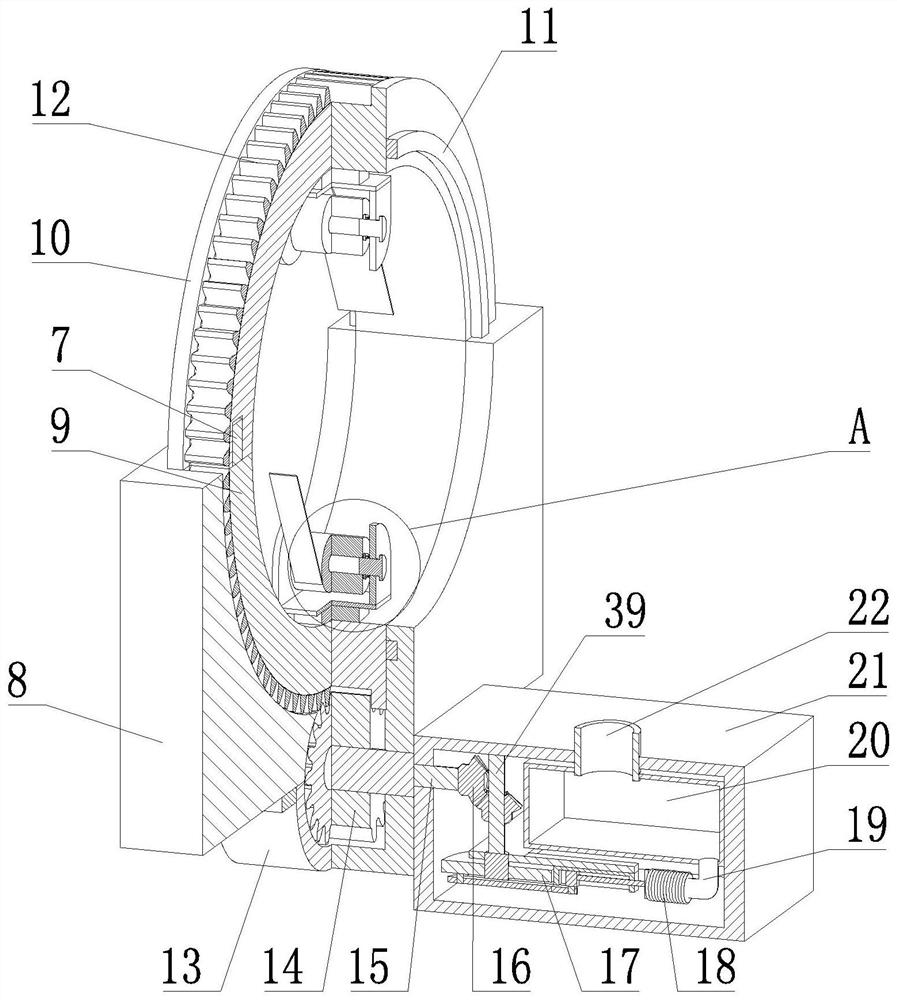

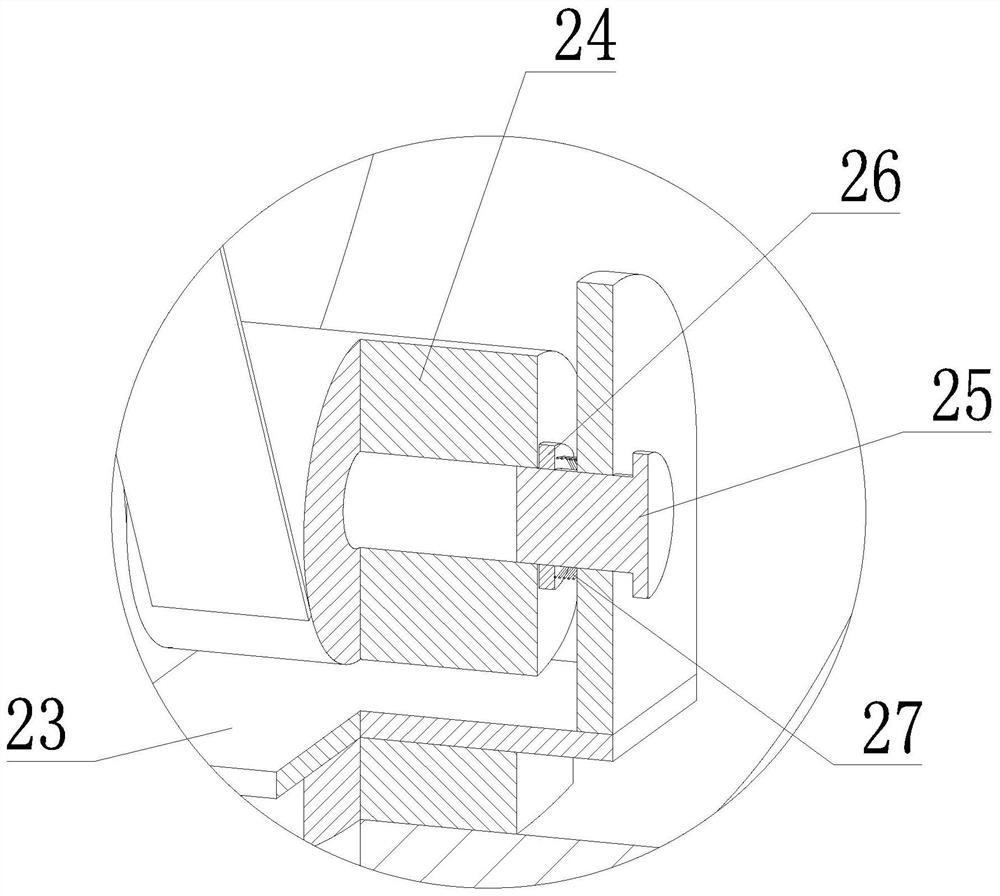

[0042] Such as Figure 2-3 As shown, the winding assembly 1 includes a locking member 7, a fixed seat 8, an upper fixed fan ring-9, a lower fixed fan ring-10, a fixed cover 13 and a gear 14; the fixed seat 8 is provided with a fan-shaped through groove, and the upper fixed fan ring The ring one 9 and the lower fixed fan ring one 10 are connected by two sets of locking parts 7; the upper f...

Embodiment 2

[0047] Compared with Embodiment 1, the present invention proposes a thermal insulation tape winding device for petroleum pipelines. The difference between this embodiment and Embodiment 1 is as follows: figure 2 with Figure 9 As shown, the automatic glue feeding assembly 4 includes a connection key 15, a transmission assembly 16, an air bag 18, a connecting pipe 19, a storage box 20 and a fixed box 21; the fixed box 21 is arranged on the fixed seat 8, and on the fixed box 21 A reciprocating device 17 is provided; the connecting key 15 is rotatably arranged on the fixed box 21 and connected with the rotating shaft of the gear 14, and the rotating shaft 39 is rotatably arranged on the fixed box 21 and connected with the reciprocating device 17, and the connecting key 15 and the rotating shaft 39 pass through the transmission Components 16 are connected by transmission; the storage box 20 is arranged on the fixed box 21, and the storage box 20 is provided with a connecting pipe...

Embodiment 3

[0052] Compared with Embodiment 1 or Embodiment 2, the thermal insulation tape winding equipment for petroleum pipeline proposed by the present invention has the following differences: figure 1 with Figure 5 As shown, it also includes a moving assembly 3; the moving assembly 3 is connected to the glue assembly 2 through a connecting assembly 6; wherein, the moving assembly 3 includes an upper fixed fan ring three 33, a lower fixed fan ring three 34 and a motor two 37; the upper fixed fan ring One end of the ring three 33 and the lower fixed fan ring three 34 is connected by hinge rotation, and the other end is connected by the locking member 7; the upper fixed fan ring three 33 and the lower fixed fan ring three 34 are all slidably connected with the second fixed frame 35, and Fixing frame two 35 is provided with threaded hole; Upper fixed fan ring three 33 and lower fixed fan ring three 34 are all provided with adjusting screw 38, and adjusting screw 38 is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com